A kind of environment-friendly high-strength elastic coating and preparation method thereof

An elastic coating, high-strength technology, applied in the direction of coating, etc., can solve the problems of poor mechanical properties and water resistance, and achieve the effect of fast curing speed, good product stability and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

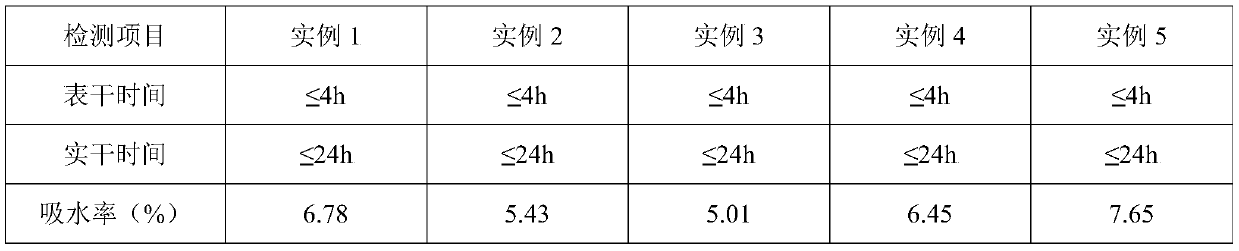

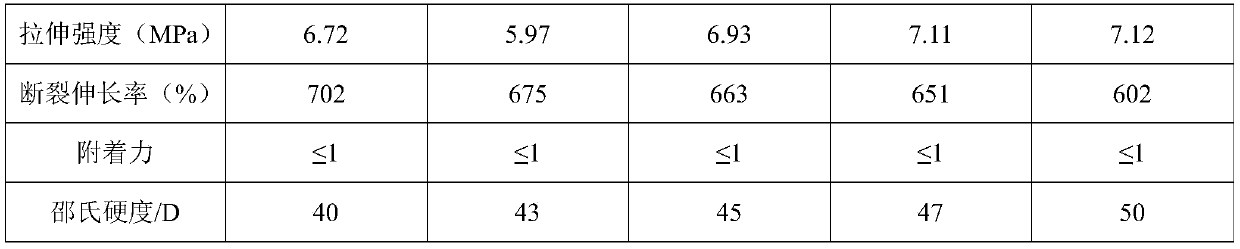

Examples

preparation example Construction

[0028] The preparation method of a kind of environment-friendly high-strength elastic paint of the present invention comprises the following steps:

[0029] a, by weight, add 40-50 parts of water, 0.5-1 part of nonionic surfactant, 0.5-1 part of anionic surfactant, 4-8 parts of octamethylcyclotetrasiloxane into the reactor, 0.4~1 part of tetramethyltetravinylcyclotetrasiloxane, react at 70~80°C for 3~4 hours, add 0.2~0.8 parts of hexamethyldisiloxane, continue to react for 2~3 hours, stop Heating and cooling to room temperature can prepare polysiloxane emulsion.

[0030] b. Using polysiloxane emulsion as seed emulsion, add 40-50 parts of polysiloxane emulsion, 1-1.75 parts of alkyl alcohol polyoxyethylene (3) ammonium DNS-18 and 0.5-1 part of polysiloxane emulsion into the reactor. Oxyethylene octylphenol ether-10, mixed solution A was prepared after stirring evenly.

[0031] c. Weigh 60-80 parts of acrylate monomers and 10-40 parts of cross-linking agent monomers. After mix...

Embodiment 1

[0035] a, by weight, add 40 parts of water, 0.5 part of nonionic surfactant, 1 part of anionic surfactant, 4 parts of octamethylcyclotetrasiloxane, 0.8 part of tetramethyltetravinyl For cyclotetrasiloxane, react at 80°C for 2 hours, add 0.2 parts of hexamethyldisiloxane, continue the reaction for 2.5 hours, stop heating, and cool to room temperature to prepare polysiloxane emulsion.

[0036] b, with polysiloxane emulsion as seed emulsion, add 50 parts of polysiloxane emulsion, 1.75 parts of alkyl alcohol polyoxyethylene (3) ammonium DNS-18 and 0.5 part of polyoxyethylene octylphenol ether into the reactor -10, mix solution A after stirring evenly.

[0037] c. Weigh 63.5 parts of acrylate monomers and 34.5 parts of cross-linking agent monomers, mix evenly and add 1 / 10 of the mixed monomers to the mixed solution A, and continue to react at 80°C for 1 Mixed solution B was prepared in 1 hour; then 0.2 parts of water-soluble initiator was dissolved in 20 parts of water to make ini...

Embodiment 2

[0043] a, by weight, add 50 parts of water, 1 part of nonionic surfactant, 0.5 part of anionic surfactant, 8 parts of octamethylcyclotetrasiloxane, 1 part of tetramethyltetravinyl For cyclotetrasiloxane, after reacting at 80°C for 4 hours, add 0.8 parts of hexamethyldisiloxane, continue the reaction for 3 hours, stop heating, and cool to room temperature to prepare polysiloxane emulsion.

[0044] b, with polysiloxane emulsion as seed emulsion, add 40 parts of polysiloxane emulsion, 1 part of alkyl alcohol polyoxyethylene (3) ammonium DNS-18 and 1 part of polyoxyethylene octylphenol ether into the reactor -10, mix solution A after stirring evenly.

[0045] c. Weigh 66 parts of acrylate monomers and 33 parts of cross-linking agent monomers, mix them evenly and add 1 / 10 of the mixed monomers to the mixed solution A, and continue to react at 70°C for 0.5 Mixed solution B was prepared within 1 hour; then 0.3 parts of water-soluble initiator was dissolved in 10 to 30 parts of water...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap