Cornice formwork support device, support and removal method on the track

A formwork and cornice technology, which is applied to the field of cornice formwork support devices on the track, can solve the problems of low construction efficiency, poor forming effect, and difficult formwork support, and achieve the effect of improving construction efficiency and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

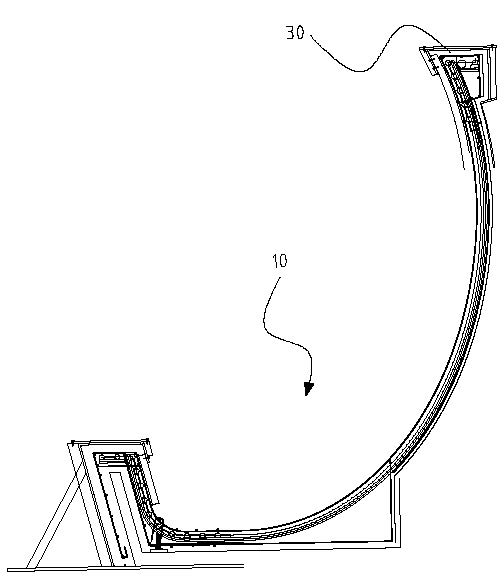

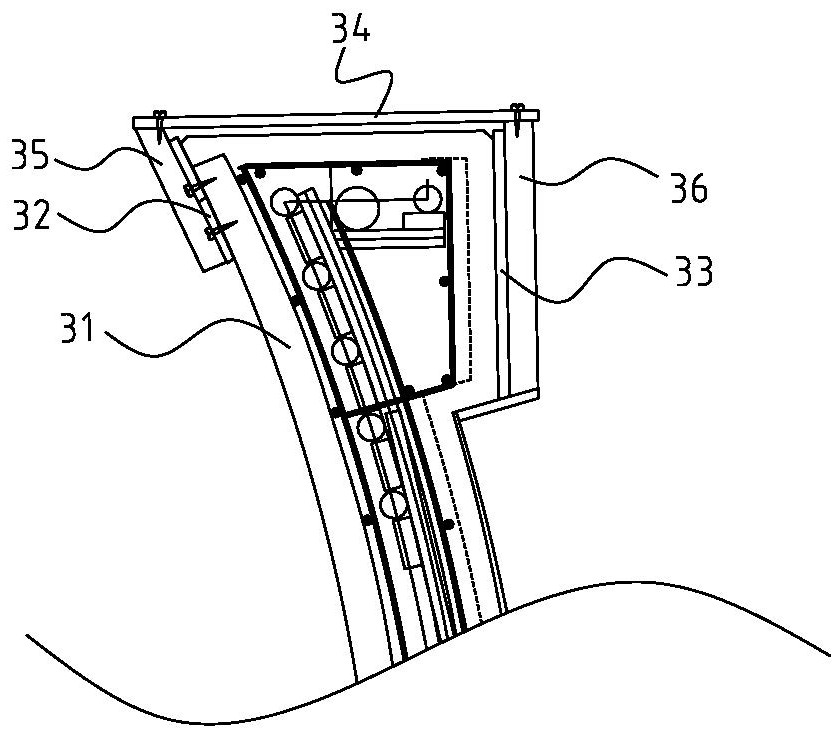

[0025] Such as figure 1 and figure 2 As shown, the present embodiment provides a supporting device for cornice formwork on the track, wherein the upper cornice 30 is located at one end of the track 10, and the upper cornice formwork supporting device includes an inner surface of the upper cornice 30 The leveling pipe 31, the inner formwork 32, and the outer formwork 33 opposite to the inner formwork 32, wherein the upper end of the inner formwork 32 is flat with the concrete design surface at the top of the upper cornice 30, and the lower end of the inner formwork 32 is pasted Close to the leveling pipe 31 , the top of the upper cornice 30 is provided with a plurality of support strips 34 along the surface of the concrete, and the support strips 34 are connected to the inner formwork 32 and the outer formwork 33 .

[0026] The cornice formwork supporting device on the track in this embodiment, wherein the upper cornice 30 is located at one end of the track 10, and the upper ...

Embodiment 2

[0032]This embodiment provides a method for supporting cornice formwork on a race track. According to the cornice formwork support device on a race track described in Embodiment 1, the upper cornice of the race track is supported, including the following steps: Step S1: along the The upper eaves 30 of the race track are arranged with an inner formwork 32, an outer formwork 33 and a leveling pipe 31, and the upper end of the inner formwork 32 is level with the concrete design surface at the top of the upper eaves 30, and the lower end of the inner formwork 32 is fixed on On the leveling pipe 31; step S2: laying a plurality of support strips 34 along the surface of the concrete on the top of the upper cornice 30, and connecting the support strips 34 to the inner formwork 32 and the outer formwork 34 .

[0033] The cornice formwork support method on the racetrack described in this embodiment, in the step S1, the inner formwork 32, the outer formwork 33 and the leveling pipe 31 ar...

Embodiment 3

[0035] This embodiment provides a method for dismantling cornice formwork on a track. The cornice formwork supporting device on a track described in Embodiment 1 is removed, including the following steps: Before the initial setting, remove the support bar 34 first; continue to remove the inner formwork 32, and then remove the leveling pipe 31 after the inner formwork 32 is dismantled; finally remove the outer formwork 33.

[0036] This embodiment provides a method for removing cornice formwork on the track. Due to formwork support spraying and formwork support spraying, there will be some staggered platforms on the joint surface, resulting in obvious delamination. Therefore, it is required to remove the formwork before initial setting , carry out the joint surface treatment in time to achieve the overall effect, specifically, after the concrete spraying and leveling of the inner surface of the upper cornice 30 are completed, before the initial setting of the concrete, the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com