Slanting backward type road shoulder wall back drainage system and construction method

A technology for drainage system and road shoulder, which is applied in the field of drainage system behind inclined road shoulder wall, which can solve the problems of increased load, increased saturated area of sliding body, damage, etc., and achieves the effect of convenient and fast construction and easy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

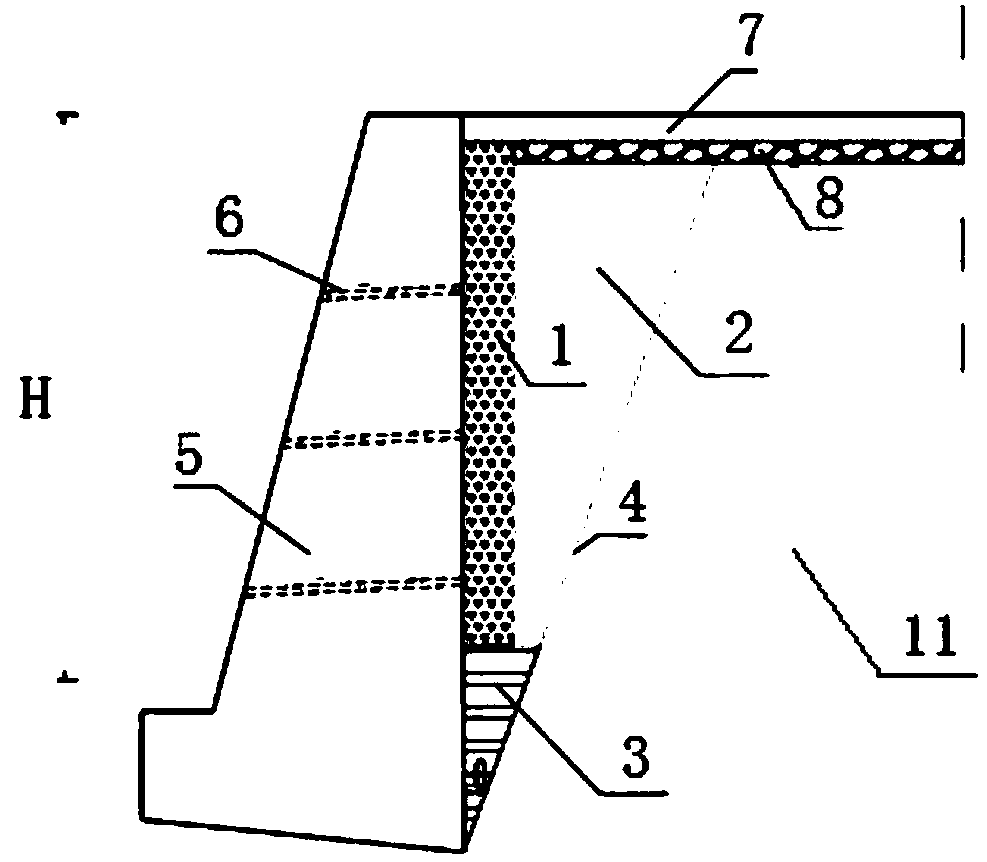

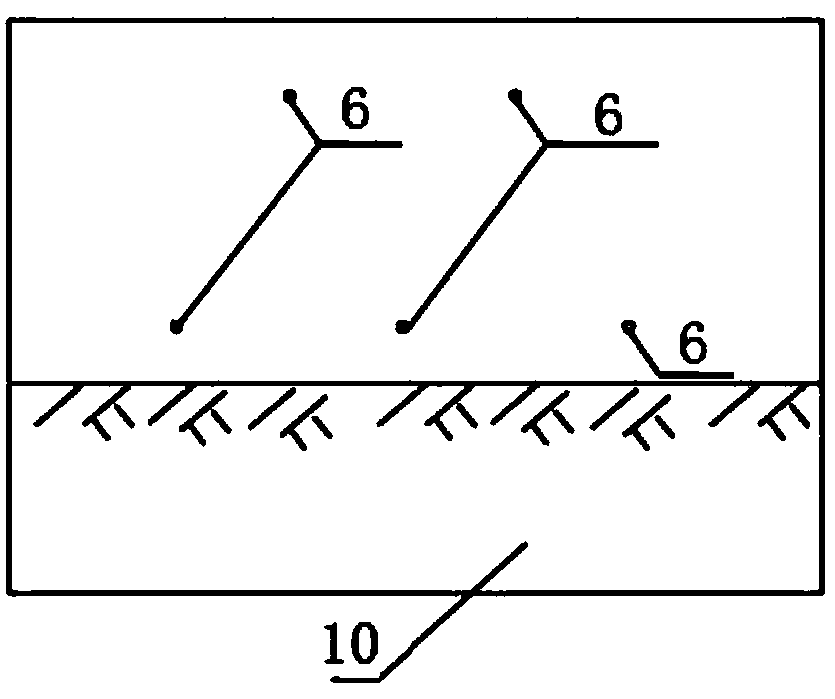

[0076] Example 1, see figure 1 , Figure 3-Figure 6 , a drainage system behind an inclined road shoulder wall, which includes a gravel or pebble filter layer 1, a water-permeable material 2, a permeable geotextile 4, a drain pipe 6, and a graded gravel subbase 8. The gravel or pebble filter layer 1 has a width of 30 cm and is placed inside the retaining wall 5 . The upper part is the pavement structure layer 7 and the lower part is the cohesive soil 3 . The permeable material 2 is mainly composed of medium-coarse sand, wrapped by a composite geomembrane, placed between the gravel or pebble filter layer 1 and the backfill roadbed 11, and has an inverted right-angled triangle structure, with one vertical side close to the graded gravel subbase 8. The other vertical side is close to the inner side of the retaining wall 5, that is, the water-permeable material 2 gradually increases from bottom to top. The permeable geotextile 4 is arranged along the side slope of the backfill ro...

Embodiment 2

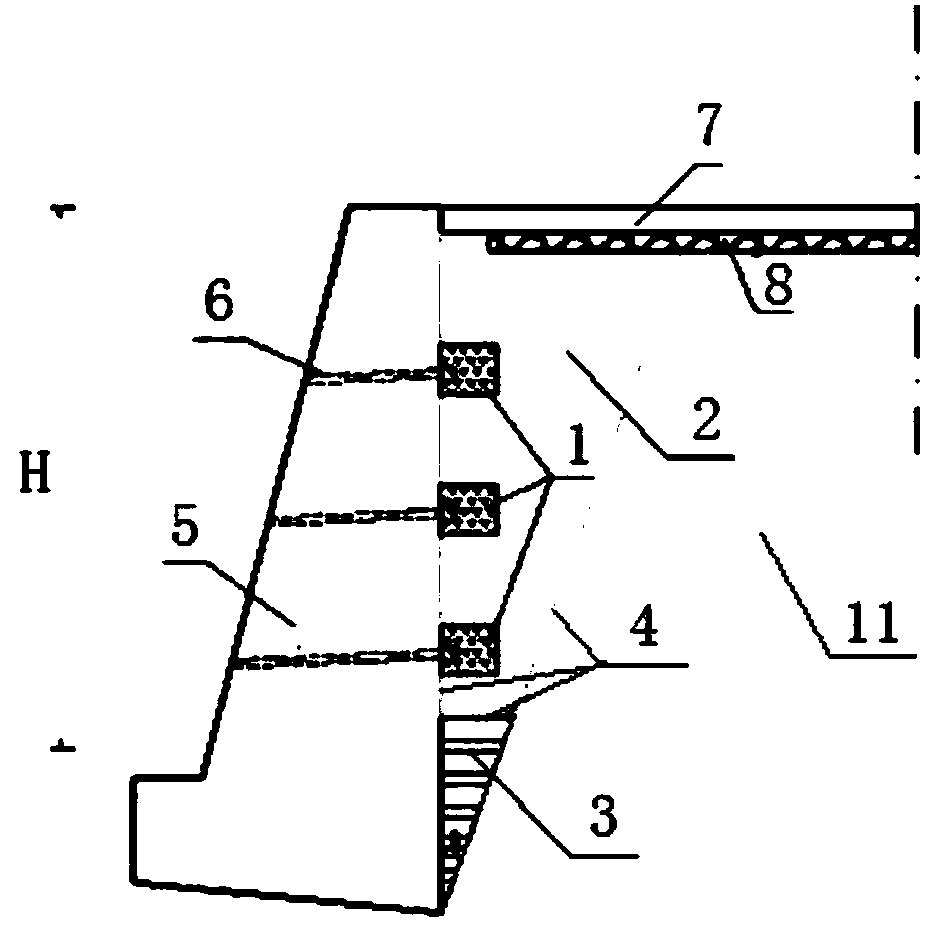

[0098] Example 2, see Figure 2-Figure 6 , a drainage system behind an inclined road shoulder wall, which includes a gravel or pebble filter layer 1, a water-permeable material 2, a permeable geotextile 4, a drain pipe 6, and a graded gravel subbase 8. There are multiple gravel or pebble filter layers 1, which are placed inside the retaining wall 5 and are located at the drain holes respectively. The permeable material 2 is mainly composed of medium-coarse sand, wrapped by a composite geomembrane, placed between the retaining wall 5 and the backfill roadbed 11, and has an inverted right-angled triangle structure, one vertical side is close to the graded crushed stone subbase 8, and the other is vertical The side is close to the inner side of the retaining wall 5, that is, the water-permeable material 2 gradually increases from bottom to top. The gravel or pebble filter layer 1 is embedded on the water-permeable material 2; the water-permeable geotextile 4 is arranged along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com