Multifunctional replaceable coupling beam structure

A multi-functional, connecting beam technology, applied in truss structures, joists, girders, etc., can solve problems such as poor displacement control effect, shear damage, and insignificant improvement, and avoid post-earthquake repair and reinforcement costs. , Improve the ability of rapid recovery, and facilitate the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

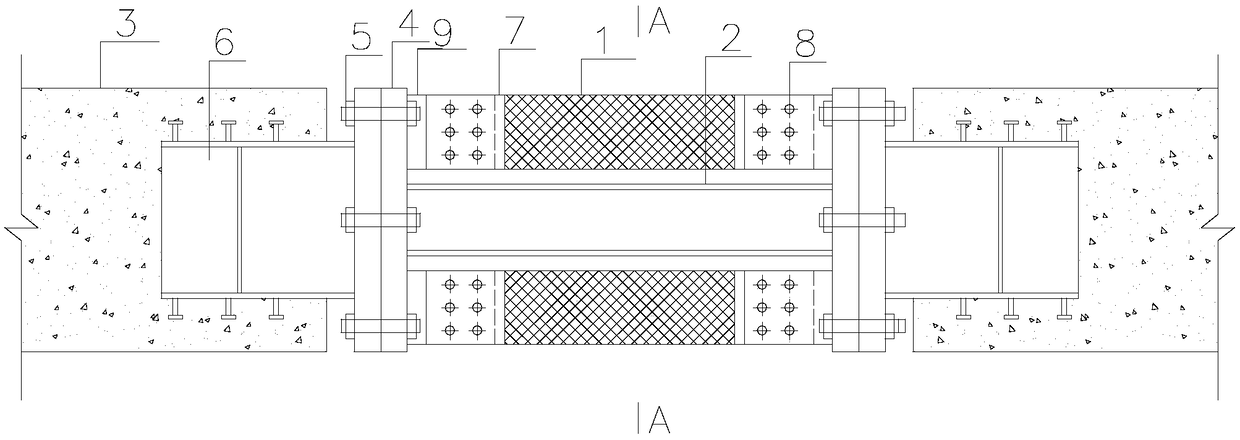

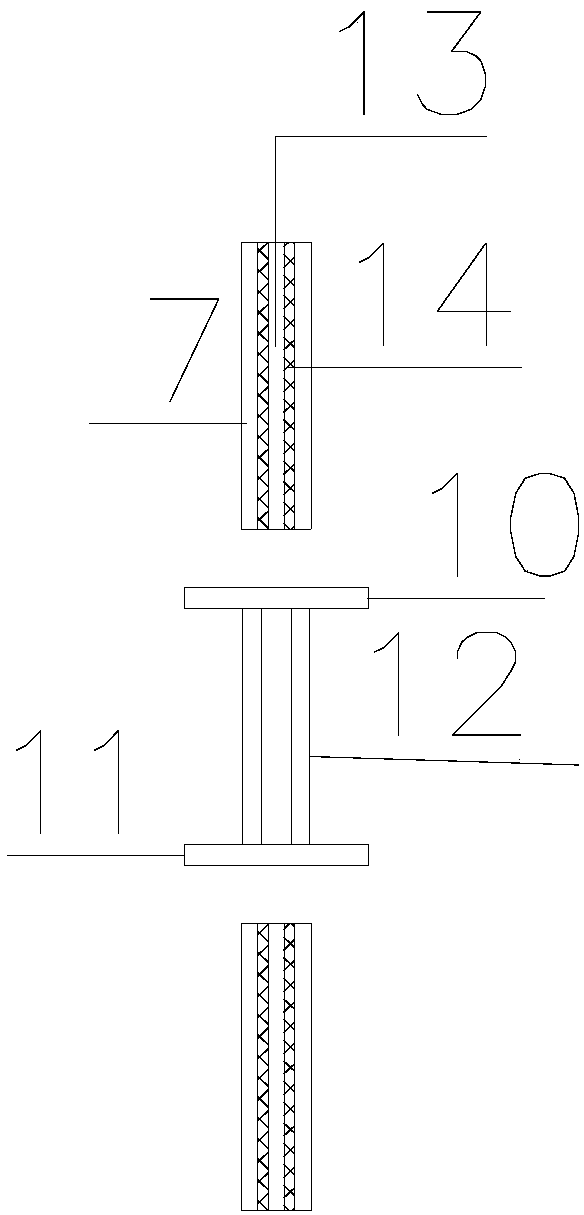

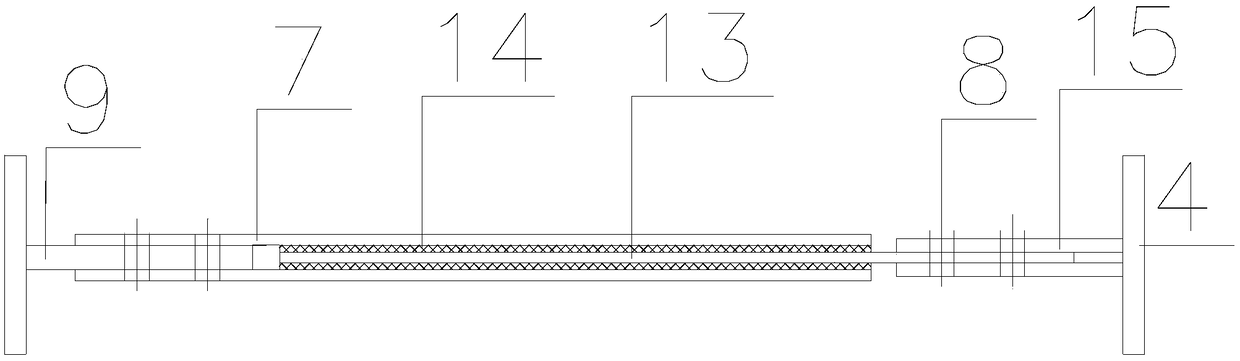

[0026] Such as figure 1 and 2 As shown, the new replaceable connecting beam structure with a composite damper of the present invention includes a viscoelastic damper 1, a metal damper 2, a non-replaceable section 3 and an embedded part 6. The metal damper 2 is composed of an upper flange 10, a lower flange 11 and a plurality of parallel webs 12. The webs are made of steel with a low yield point, and the flanges 10 and 11 are welded together with the webs. Lower shear yield energy dissipation. The viscoelastic damper is composed of rubber layer 14, inner steel plate 13 and outer steel plate 7, which can dissipate energy under the action of wind vibration and small earthquake. The metal damper 2 and the viscoelastic damper 1 are connected in parallel and welded with the end plate 4 . The bending strength and shear strength of the non-replacement section 3 are greater than those of the composite damper, ensuring that the non-replacement section does not yield under the action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com