Deflection correction method for clay conveying pump of heading machine

A technology of roadheader and conveying pump, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc. It can solve the problems of large limitation of grouting pressure control, failure to achieve deviation correction effect, general deviation correction effect, etc., to achieve control of surface subsidence, Superior economic benefit, good effect of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

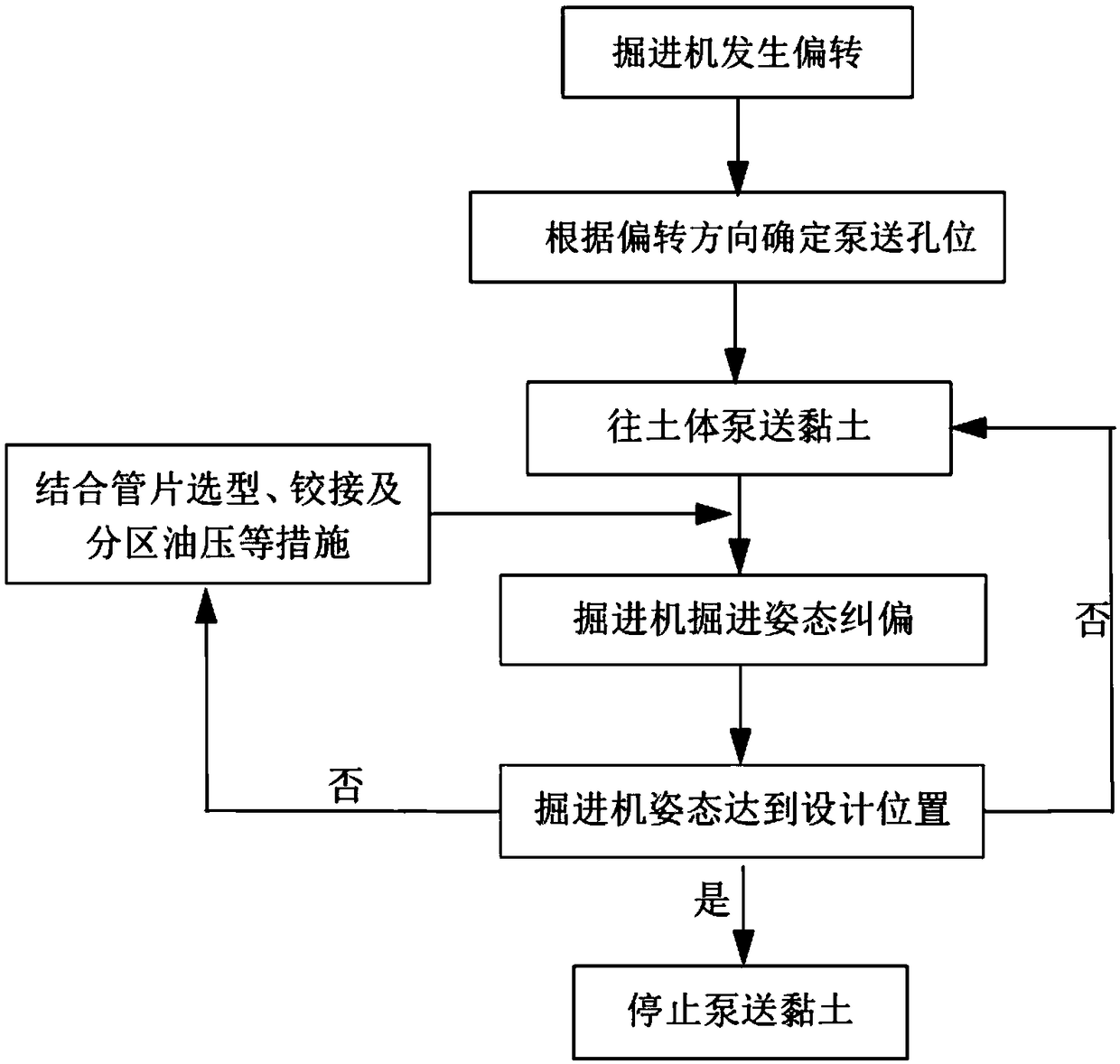

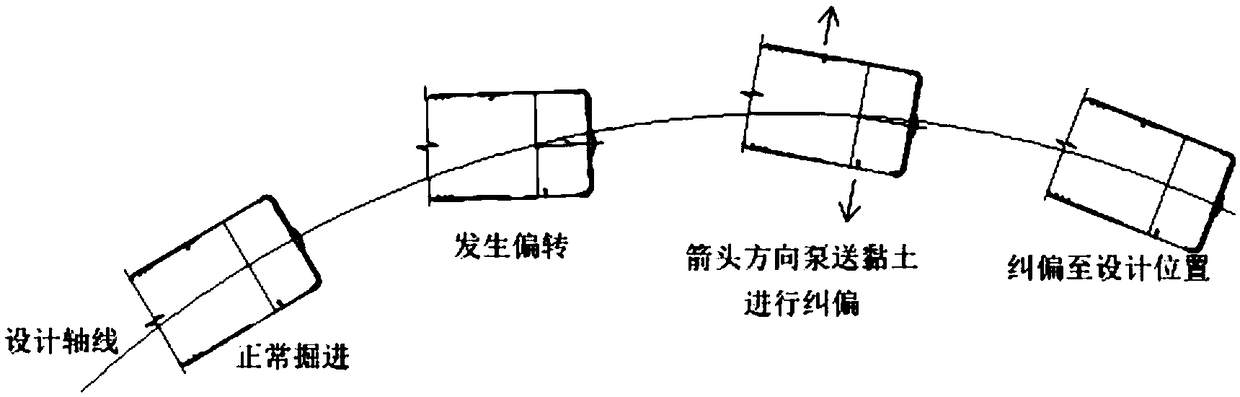

[0027] like figure 1 , 2 As shown, a method for correcting the deviation of a roadheader clay conveying pump includes the following steps:

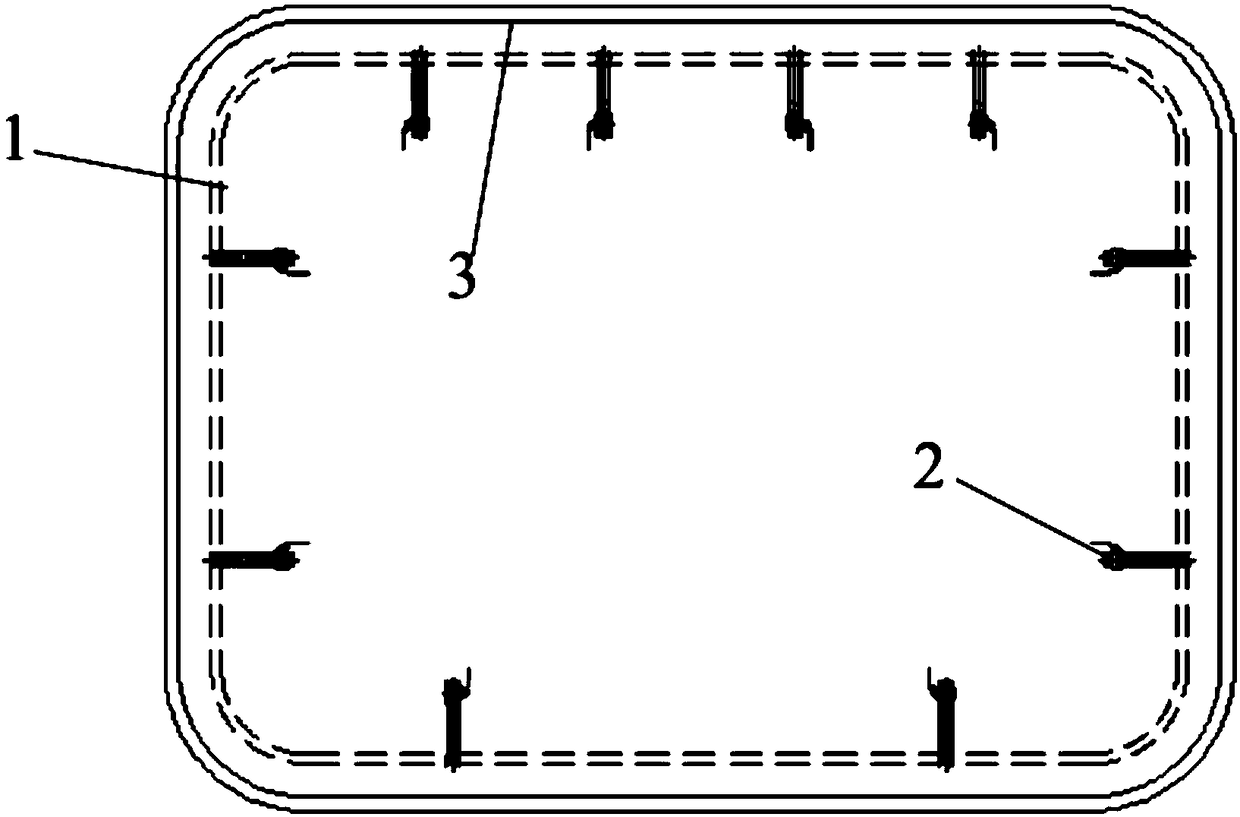

[0028] (1) Determination of the pumping hole 2: According to the deflection direction of the roadheader 1, select a reserved hole on the casing 3 of the roadheader in the same direction as the deflection direction or re-open the hole as the pumping hole 2. Specifically, when the front casing of the roadheader 1 is deflected to the left and the rear casing is deflected to the right, select the hole on the left side of the front casing of the roadheader 1 or the hole on the right side of the rear casing or both at the same time as the pumping hole 2. When the front casing of the roadheader 1 is deflected to the right and the rear casing is deflected to the left, select the right hole of the front casing of the road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com