Wet spray construction process

A construction technique and wet spraying technology, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of low wet spraying quality and cumbersome operation of wet spraying process, and achieve low labor intensity, low rebound rate of shotcrete, The effect of convenient and safe operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

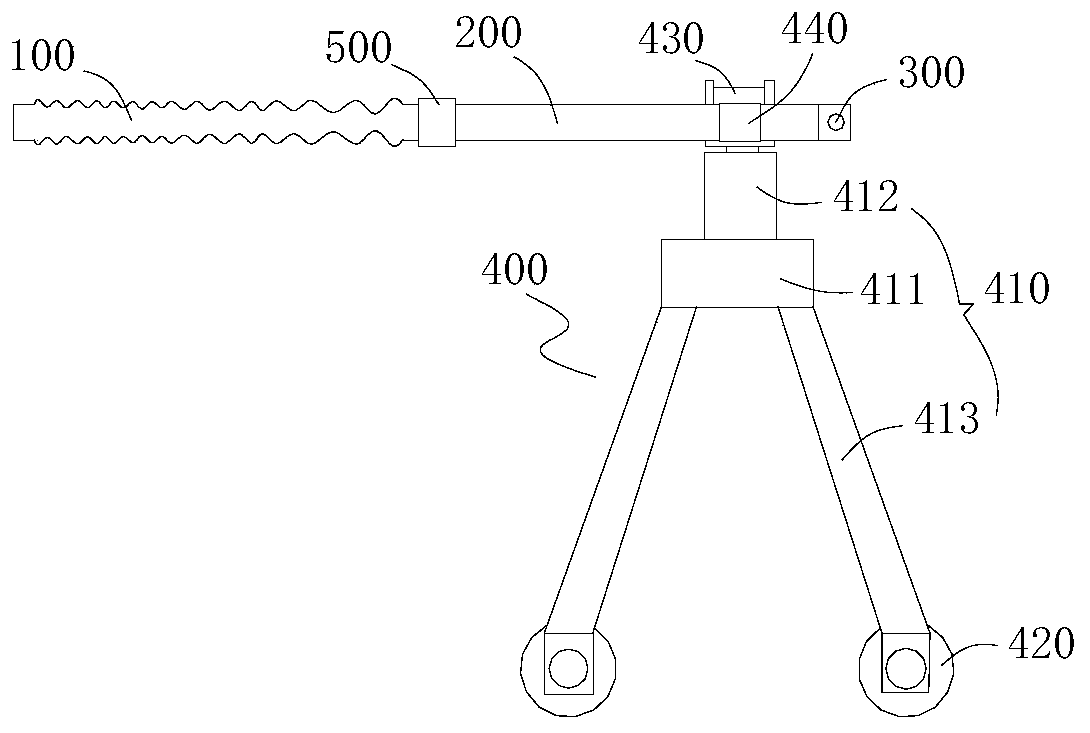

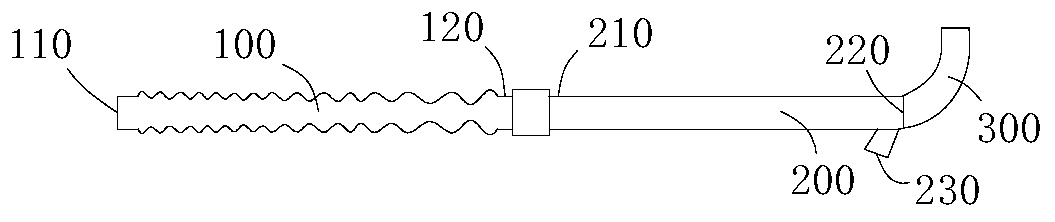

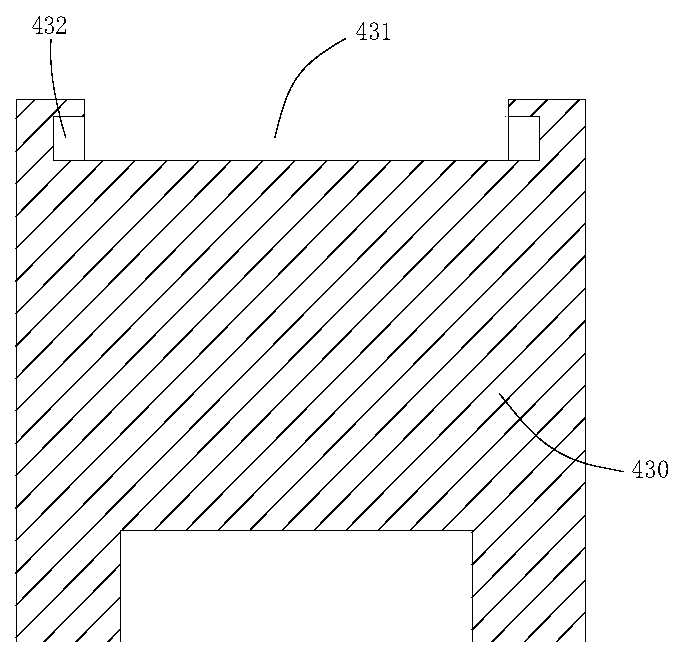

[0037] see figure 1 - Figure 8 , the present embodiment provides a kind of wet spraying construction technique, is used for the wet spraying operation of tunnel, and this construction technique comprises the following steps:

[0038]Use the wet spray manipulator to spray the concrete mixture, first spray the side wall of the tunnel, spray from bottom to top when spraying the side wall, and spray the discharge port of the wet spray manipulator perpendicular to the side wall, the discharge port The distance from the side wall is 0.8m-1.2m. Then, the arched top of the tunnel is sprayed, and the whole wet spraying operation is carried out step by step from one end of the tunnel to the other end.

[0039] Optionally, the concrete mixture includes cement, coarse aggregate, fine aggregate, quick-setting agent, water reducer and water, and the weight of the cement, coarse aggregate, fine aggregate, water reducer and water The share ratio is (450-480): (860-880): (931-945): (22.5-25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com