Single-cylinder spiral airflow engine

A technology of spiral airflow and engine, which is applied to engine components, machines/engines, non-variable-capacity engines, etc., can solve the problems of low engine efficiency, pollute the environment, and low function conversion efficiency, achieve high efficiency, ensure safety performance, The effect of delaying the ignition and detonation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

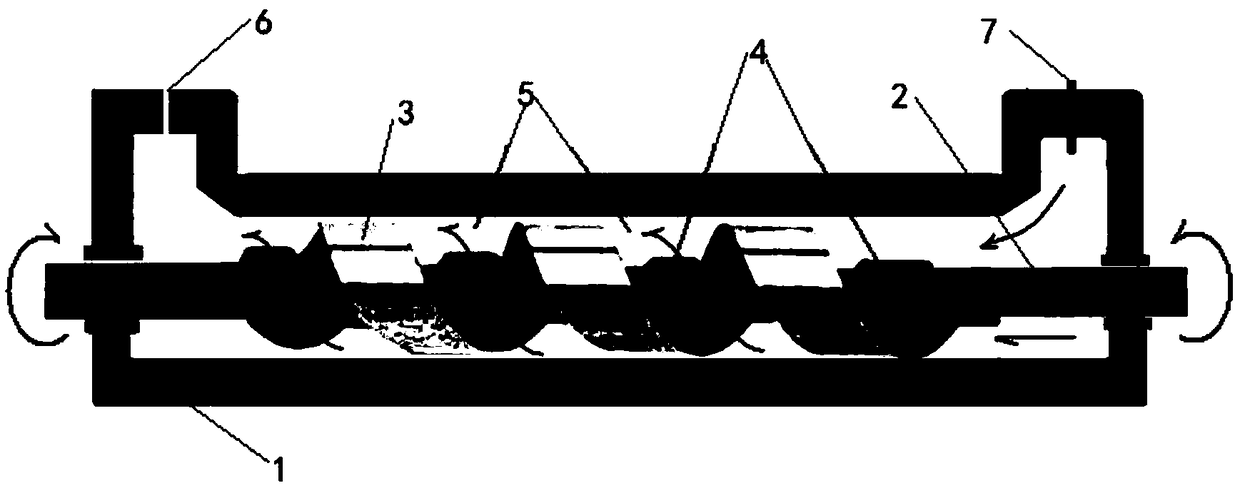

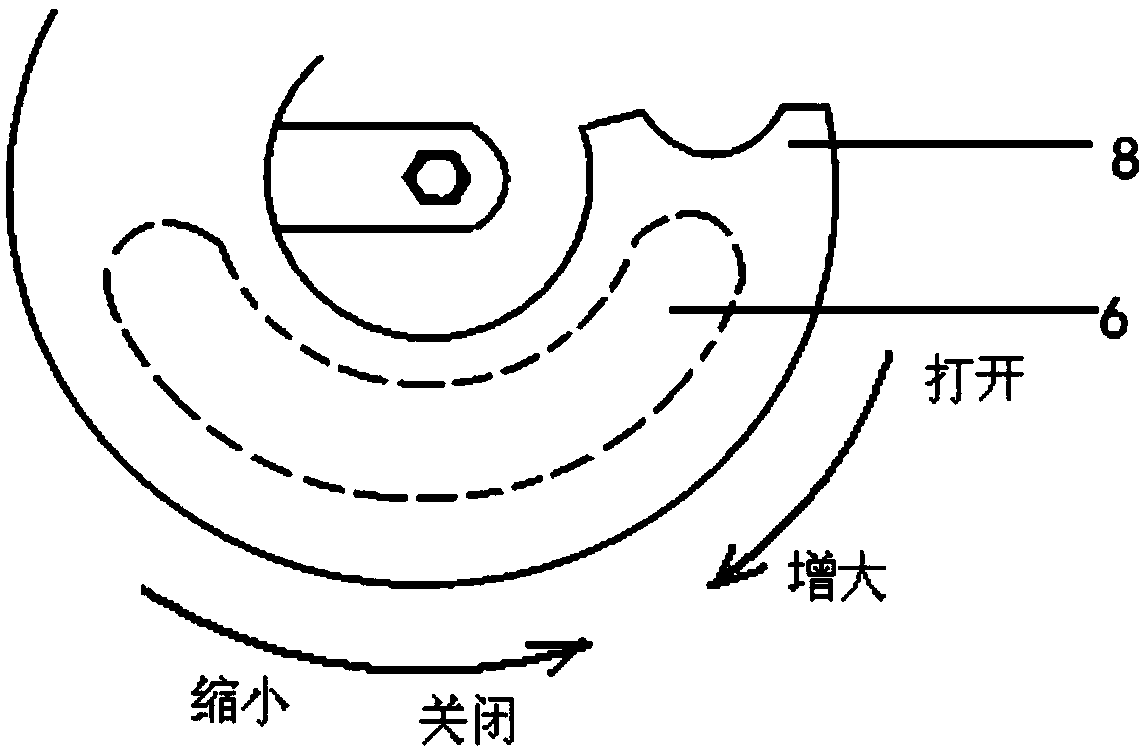

[0033] Such as figure 1 and Figure 6 Shown, the invention provides a kind of single-cylinder helical flow engine, comprising:

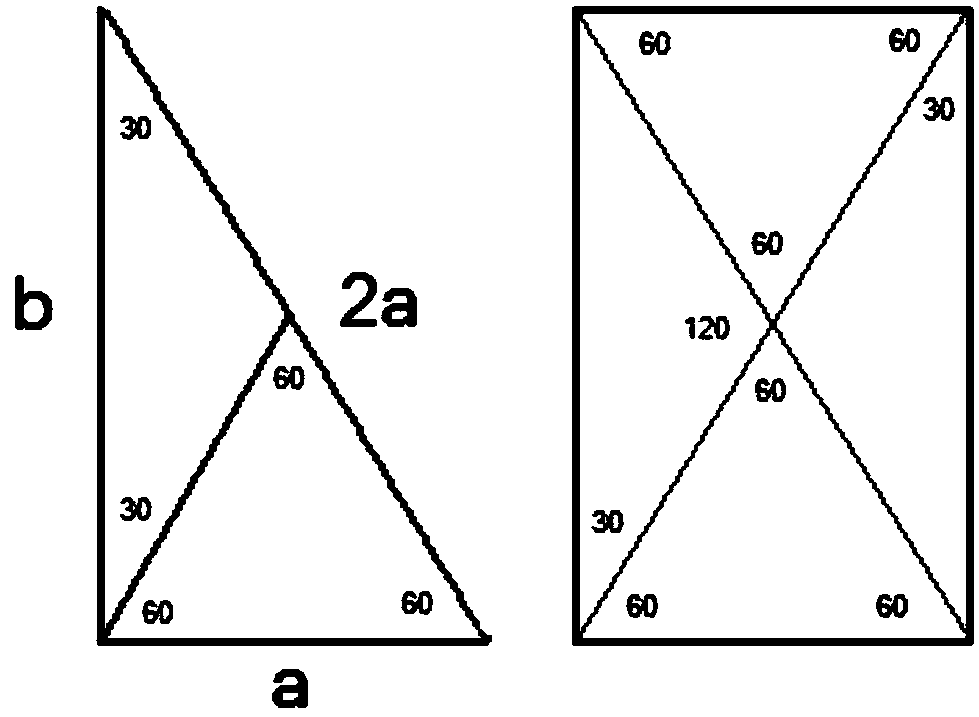

[0034] The cylinder block 1 and the cylinder shaft 2 arranged along the axis of the cylinder block, the helical impeller 3 spirally arranged along the circumference of the cylinder shaft 2, and the spiral impeller 3, the inner wall of the cylinder block 1 and the cylinder shaft 2 define a directional spiral air flow channel 5;

[0035] The resistance protrusion 4 is arranged on the cylinder shaft 2 and is located in the spiral air flow passage 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com