Variable frequency electromagnetic boiler

A boiler and electromagnetic technology, applied in the field of frequency conversion electromagnetic boiler, can solve the problems of electric boiler heating technology is not very mature, short service life, large maintenance, etc., to achieve the effect of good insulation, no maintenance costs, long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

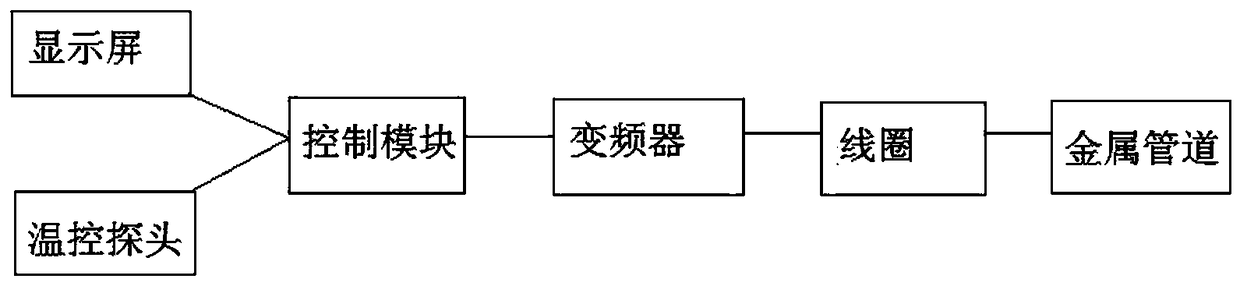

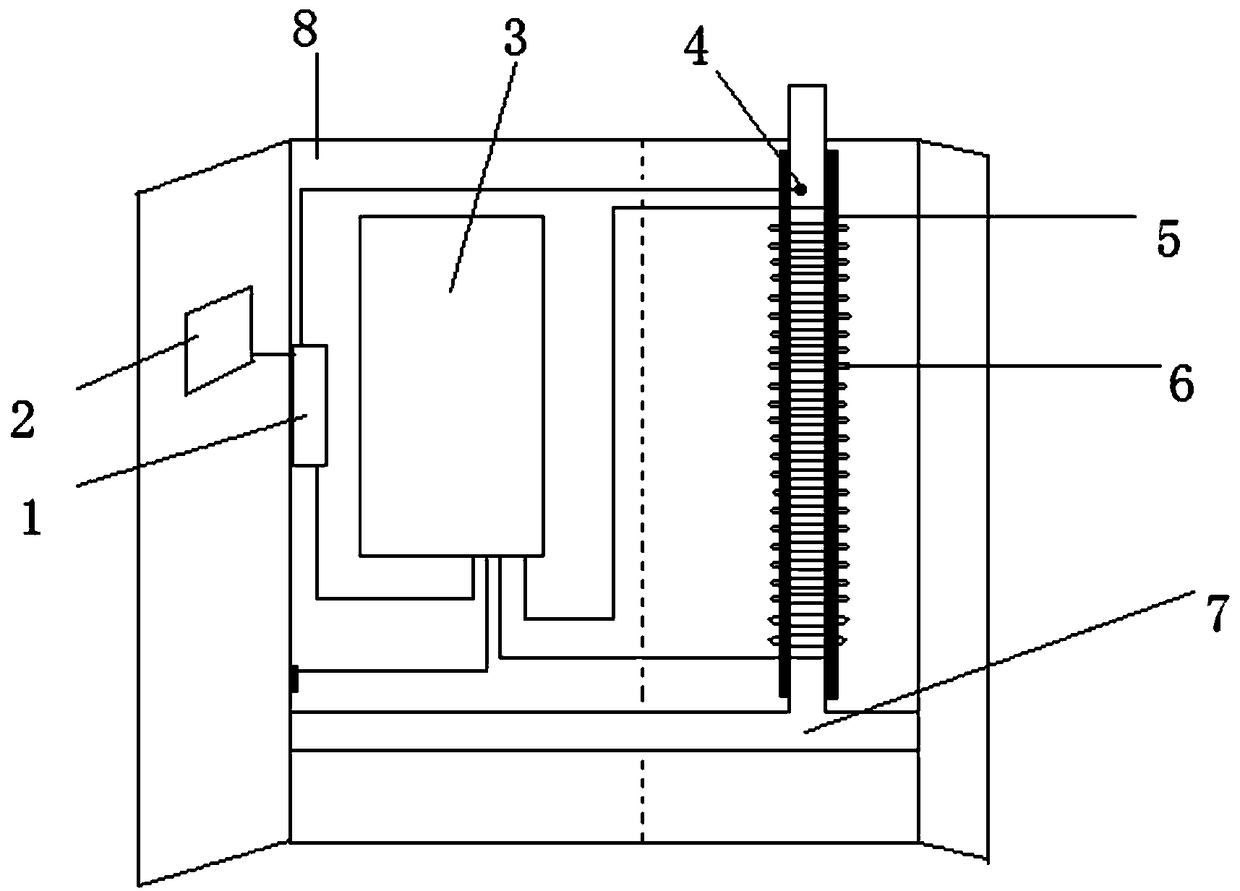

[0015] Such as figure 1 , 2 As shown, the present invention discloses a variable frequency electromagnetic boiler, which includes a furnace body 8, a metal pipe 7, a coil 6, an insulating layer 5, a temperature control probe 4, a frequency converter 3, a control module 1, and a display screen 2 , the display screen 2 is connected to the control module 1, the control module 1 is connected to the frequency converter 3 and the temperature control probe 4, the frequency converter 3 is connected to the coil 6, the inner layer of the coil is an insulating layer 5, and the insulating layer 5 is wrapped with a metal pipe 7, all The outermost layer of the accessories is the furnace body 8, and liquid is arranged in the metal pipe.

Embodiment 2

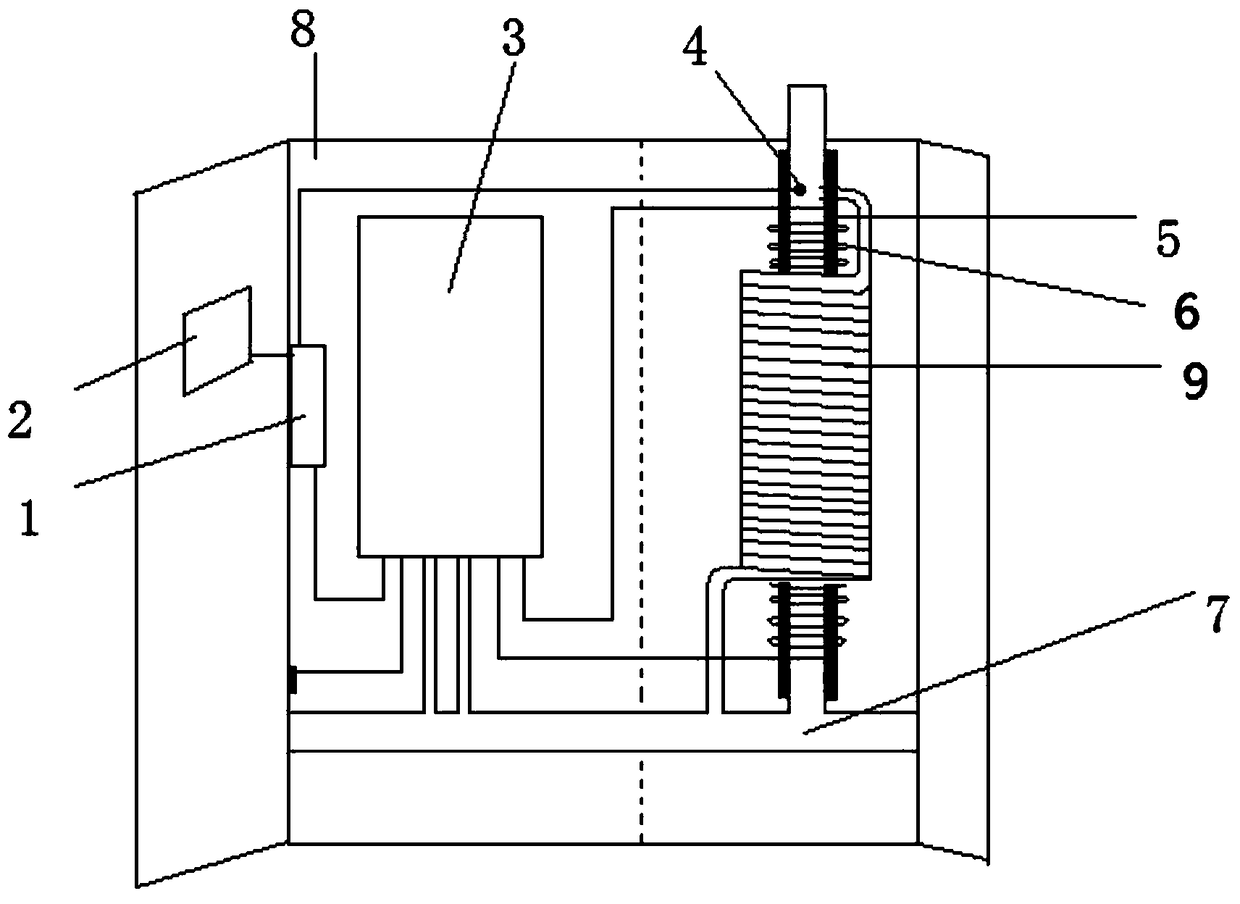

[0017] image 3 It is a schematic diagram of double-barrel heating of a frequency conversion electromagnetic boiler high temperature coil in the present invention, as shown in image 3 As shown, the present invention discloses a frequency conversion electromagnetic boiler. The difference from Embodiment 1 is that a second layer of metal pipes 9 is arranged outside the coil.

[0018] The second layer of metal pipe 9 is hollow and spirally wound outside the coil 6, and the liquid in the two layers of pipes communicates; the frequency converter 3 in Embodiment 2 is water-cooled.

[0019] In the present invention, a plurality of frequency converters can be connected in series or in parallel to form a group, the frequency converters are respectively connected to the coils wrapped in metal pipes, and the metal pipes are connected in series or in parallel.

[0020] The frequency conversion electromagnetic boiler of the present invention is currently unattended, and can achieve remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com