Spray belt cooling water high and low temperature dual control system with a plurality of stainless steel water pools being connected in series

A cooling system and cooling water technology, applied in the direction of furnace cooling, furnace control device, processing of discharged materials, etc., can solve the loss of tens of thousands, or even hundreds of thousands of yuan, high cost of reinforced concrete pools, water seepage in reinforced concrete pools, etc. problems, achieve full utilization of energy, save investment in pool scrapping and reconstruction, and speed up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

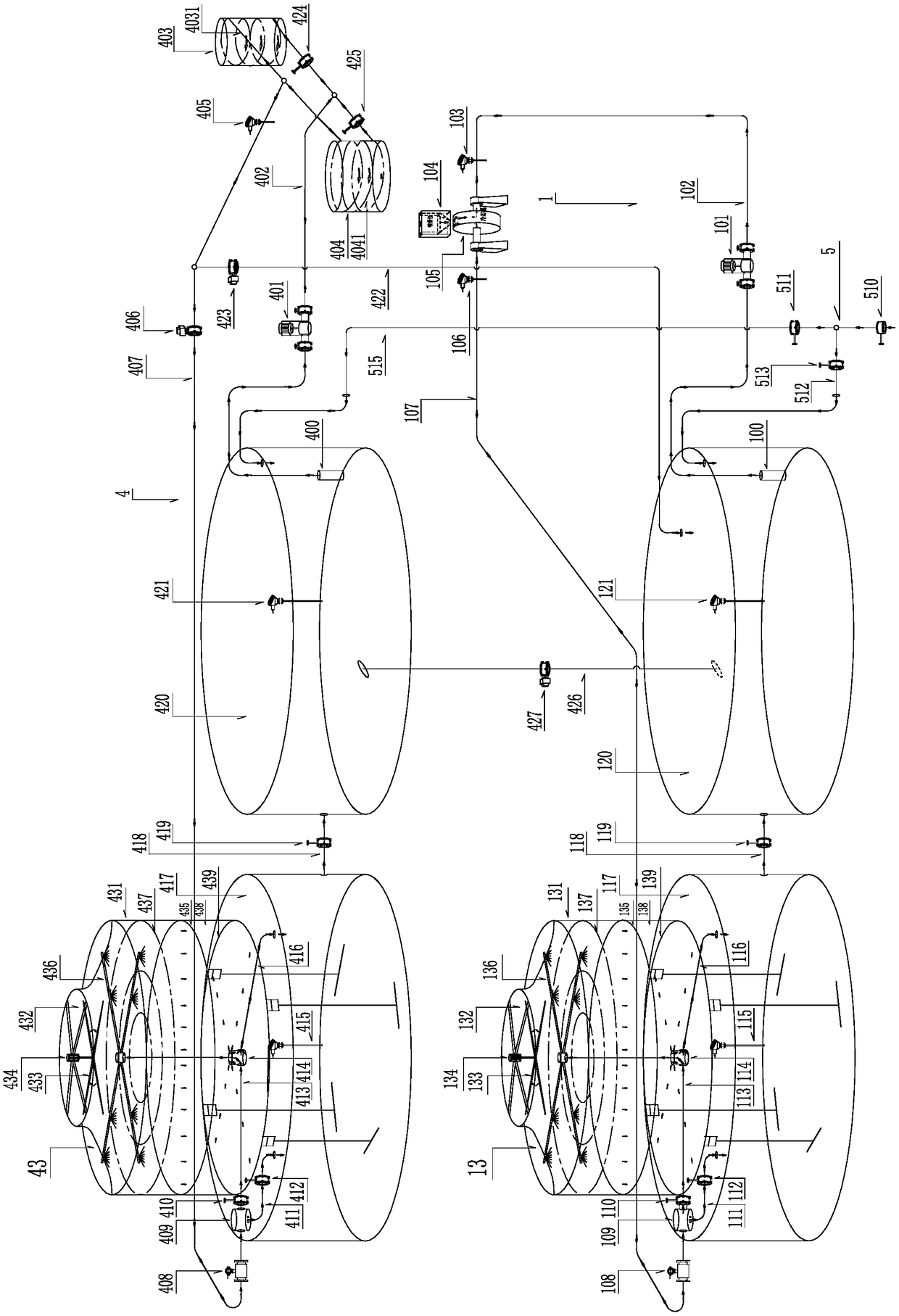

[0028] Such as figure 1 As shown, a plurality of stainless steel water pools are connected in series with spray belt cooling water high and low temperature dual control system, including spray belt production line system 1 and smelting furnace holding furnace system, and also includes the first cooling water temperature control system 11 and the second cooling water temperature control system 41 respectively connected demineralized water supply system 5. The spray belt production line system 1 is equipped with a first cooling water temperature control system 11 ; the smelting furnace holding furnace system is equipped with a second cooling water temperature control system 41 .

[0029]The first cooling water temperature control system 11 comprises two 1.1# stainless steel pools 117 and 1.2# stainless steel pools 120 connected in series, and 1# cooling tower 13 is installed on the upper end of 1.1# stainless steel pools 117. 1.1# stainless steel pools 117 and 1.2# stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com