Device and method for detecting air tightness of casing of automobile reducer

A technology of airtight detection and reducer, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc., which can solve the problems of inability to realize automatic operation, high requirements for workers' sense of responsibility, and inability to read Leakage and other issues, to achieve the effect of easy computer communication, high degree of automation, high application rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described below in conjunction with the drawings and specific embodiments.

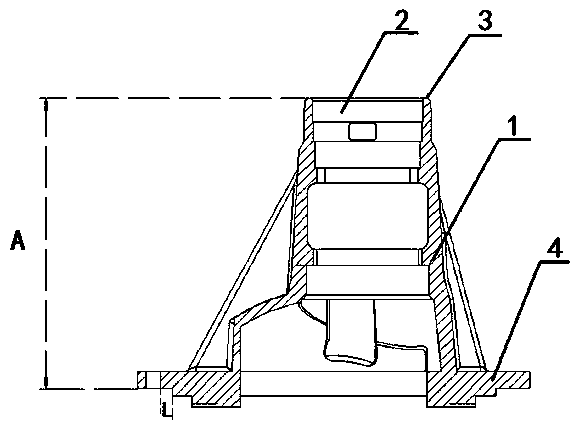

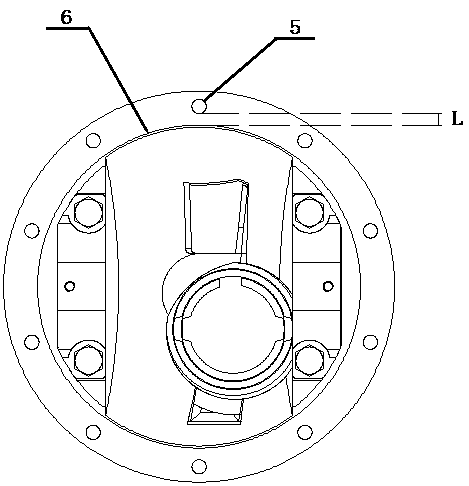

[0039]The invention provides an airtight detection device for an automobile reducer housing, which seals the end face (3) of the oil seal hole (3) at the upper end of the reducer housing (1) and the lower end flange surface (4) and prevents casting defects of the reducer housing (1) A series of processes, such as detection, are automatically controlled by the PLC control system.

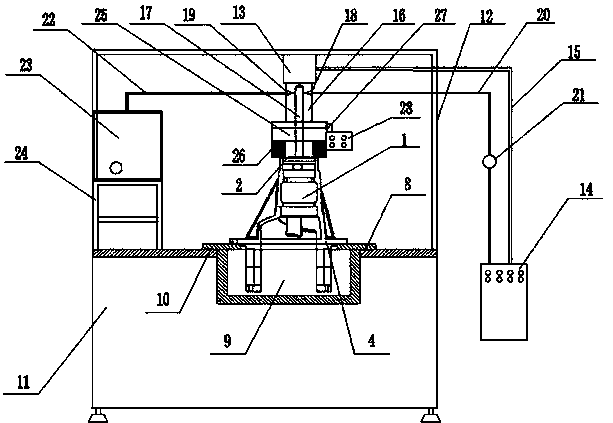

[0040] like image 3 , Figure 4 As shown, the present invention includes a press device, an upper sealing device, a lower sealing device, an air supply system, a low-pressure leak detection system, and a main control system. The press device includes a press frame (12) and a cylinder (13), and the press frame (12) is fixed on the equipment platform (8) with bolts, and the cylinder (13) is fixed on the upper part of the press fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com