Particle field measurement device based on infrared holography

A particle field and infrared technology, applied in the field of infrared holography, can solve problems such as the inability to obtain real information of other particles, achieve high resolution and improve imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

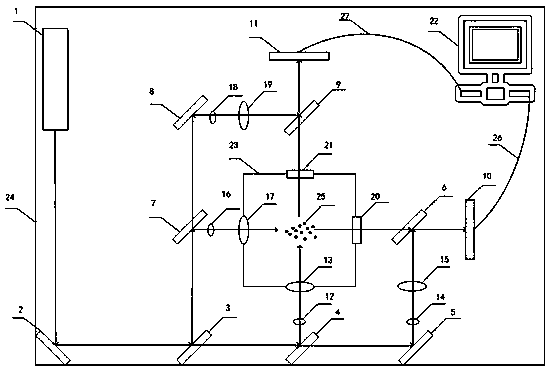

[0024]A device using infrared holography for particle field measurement, including an infrared laser 1, an infrared total reflection mirror I2, an infrared beam splitter I3, an infrared beam splitter II4, an infrared total reflection mirror II5, an infrared beam splitter III6, an infrared beam splitter Beam splitter Ⅳ7, infrared total reflection mirror Ⅲ8, infrared beam splitter Ⅴ9, infrared CCD Ⅰ10, infrared CCD Ⅱ11, infrared beam expander Ⅰ12, infrared collimator Ⅰ13, infrared beam expander Ⅱ14, infrared collimator Ⅱ15, infrared beam expander Mirror Ⅲ16, infrared collimating mirror Ⅲ17, infrared beam expander Ⅳ18, infrared collimating mirror Ⅳ19, germanium flat crystal Ⅰ20, germanium flat crystal Ⅱ21, computer 22, inner shell 23, outer shell 24, particle field to be measured 25, Data line Ⅰ26, data line Ⅱ27, the infrared laser emitted by infrared laser 1 is reflected by the infrared total reflection mirror Ⅰ2 to the infrared beam splitter Ⅰ3, and the infrared beam splitter Ⅰ3...

Embodiment 2

[0032] The structure of this embodiment is the same as that of Embodiment 1, except that:

[0033] The whole device is protected and fixed with an opaque shell, the shell is divided into an inner shell 23 and an outer shell 24, the inner and outer shells are integrated, similar to the square structure of the "back", the inside of the back is empty; The four sides of the inner shell 23 are provided with four round holes, which are respectively embedded with infrared collimating lens I13, infrared collimating lens III17, germanium flat crystal I20, and germanium flat crystal II21, which are respectively used for beam expansion of infrared laser beams. Collimate output, receive and filter out the interference of visible light to improve imaging quality. The infrared laser emitted by the infrared laser 1 is a wave source within the range of 8-13 μm in the infrared atmospheric window band, so as to avoid rapid attenuation when propagating in the air.

[0034] The infrared beam spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com