Audible sound measurement device and method for GIL breakdown positioning

A technology of measuring device and measuring method, applied in the direction of using acoustic measurement for testing, testing dielectric strength, etc., can solve the problems of high requirements on sensor durability and anti-interference ability, unstable measurement effect, damage to GIL equipment, etc. Achieve the effect of improving real-time responsiveness, reducing economic and maintenance costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An audible sound measurement method, characterized in that: a plurality of acoustic sensors are arranged along the length direction of the GIL pipe gallery,

[0062] Methods include:

[0063] Obtaining multiple acoustic signals collected by the acoustic sensor;

[0064] Perform real-time preliminary processing on the obtained acoustic signal, and extract the acoustic signal data that meets the trigger condition when it is judged to be a breakdown acoustic signal;

[0065] Based on the extracted acoustic signal data, the location algorithm is used to calculate the breakdown location.

[0066] Further, the real-time preliminary processing includes:

[0067] The acquired acoustic signals are respectively conditioned and converted to obtain corresponding digital signals;

[0068] Based on the obtained digital signal, it is judged whether it is a breakdown acoustic signal.

[0069] Further, the audible sound measuring method is characterized in that:

[0070] Based on t...

Embodiment 2

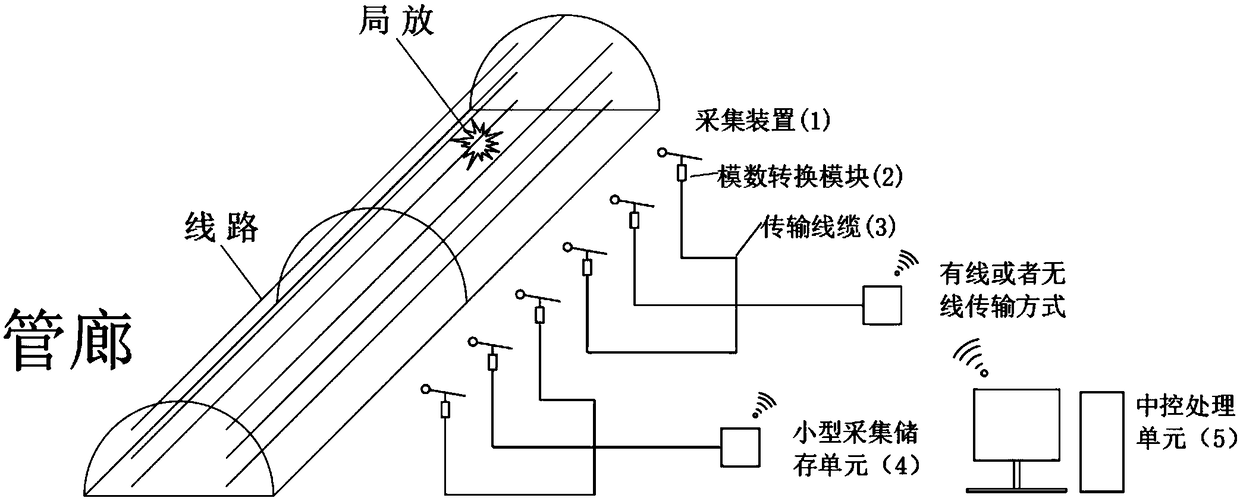

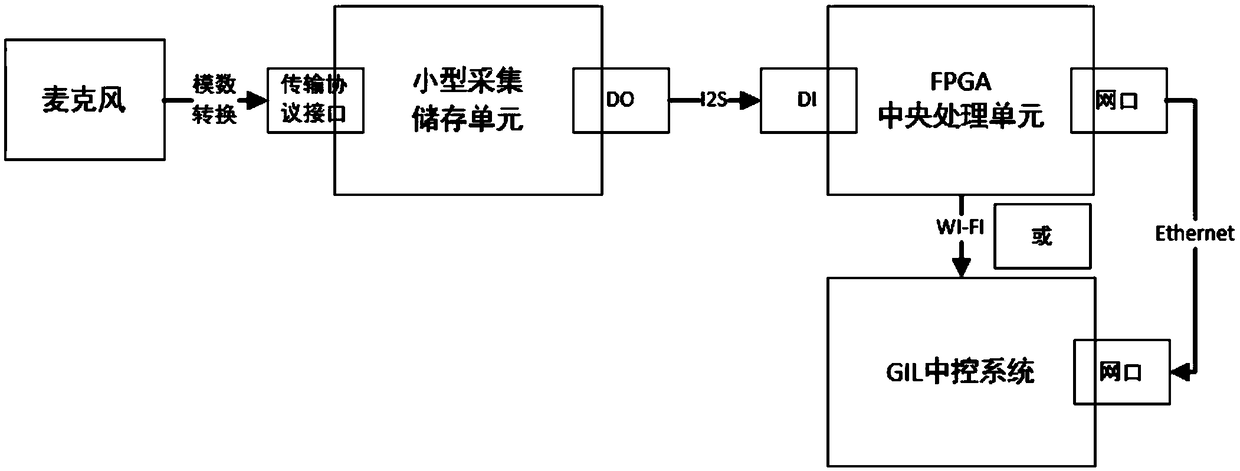

[0072] Such as figure 1 with figure 2 As shown, the present invention provides an audible sound measurement device for GIL breakdown location, including an acoustic sensor 1, an analog-to-digital conversion module 2, powering the acoustic sensor and the analog-to-digital conversion module and data for the FPGA central processing module Transmission cable 3, small acquisition and storage unit 4, and FPGA central processing module 5.

[0073] The acoustic sensors are arranged along the GIL pipe gallery;

[0074] The central processing module is used for:

[0075] Obtaining multiple acoustic signals collected by the acoustic sensor;

[0076] Perform real-time preliminary processing on the obtained acoustic signal, and extract the acoustic signal data that meets the trigger condition when it is judged to be a breakdown acoustic signal;

[0077] Based on the extracted acoustic signal data, the location algorithm is used to calculate the breakdown location.

[0078] The real-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com