Method for measuring voltage difference before and after charging or discharging of battery pack as well as measuring circuit

A measurement method and technology of battery packs, which are applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of large magnification, difficult to meet error requirements, poor precision, etc., and achieve low DC noise, high precision, and signal reduction. The effect of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

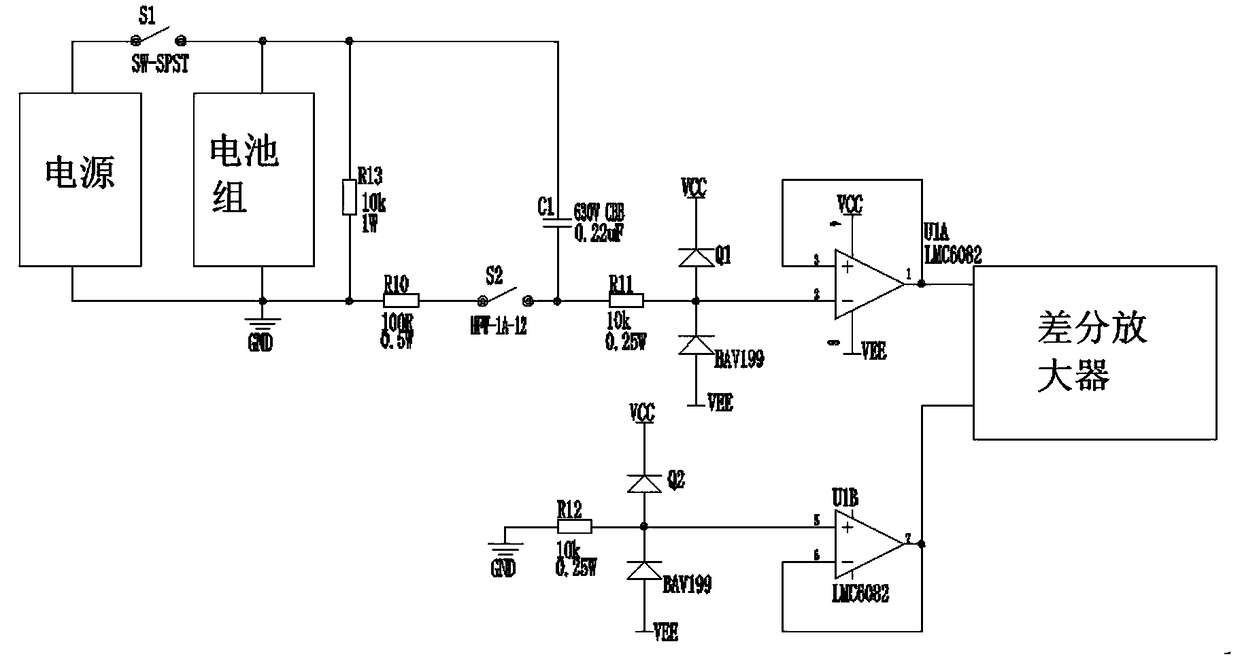

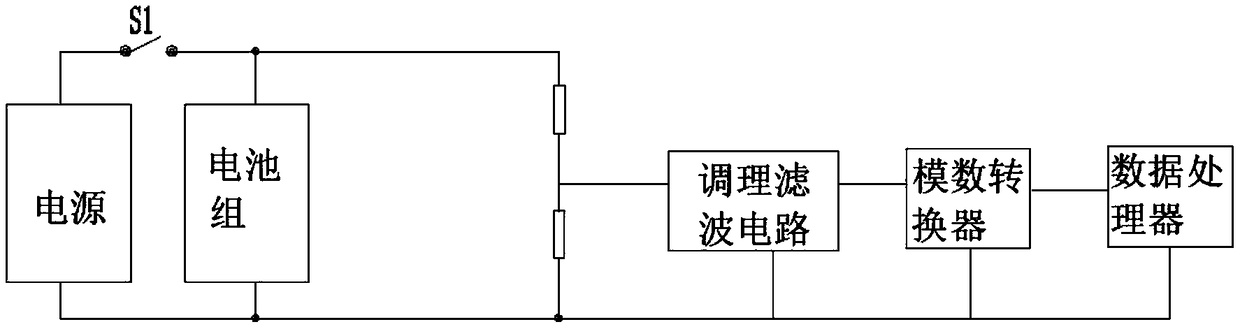

[0050] A high-precision measurement method for voltage difference before and after charging and discharging of a battery pack, comprising the following steps:

[0051] (1) Connect the battery pack to a voltage holding device, so that the voltage holding device can collect and obtain the voltage V0 of the battery pack before charging;

[0052] (2) The battery pack is disconnected from the voltage holding device, and the battery pack is connected to the power supply for charging, so as to obtain the charged voltage V1 of the battery pack;

[0053] (3) Disconnect the battery pack from the power supply, connect the voltage holding device and the battery pack to the input terminal of the differential amplifier at the same time, and connect the output terminal of the differential amplifier to the input terminal of the digital-to-analog converter, thereby obtaining at the output terminal of the digital-to-analog converter Amplified high precision voltage difference.

[0054] The vol...

Embodiment 2

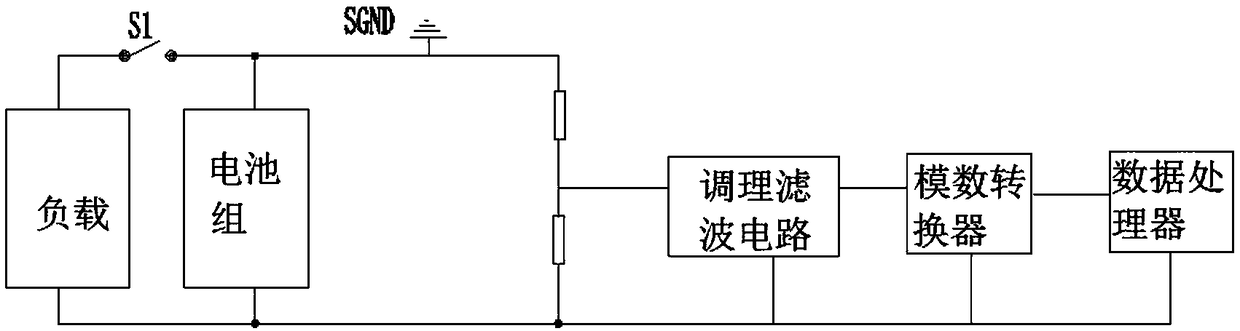

[0075] A high-precision measurement method for voltage difference before and after charging and discharging of a battery pack, comprising the following steps:

[0076] (1) Connect the battery pack to a voltage holding device, so that the voltage holding device can collect and obtain the voltage V0 of the battery pack before discharge;

[0077] (2) Disconnect the battery pack from the voltage holding device, connect the battery pack to the load and discharge, and obtain the discharged voltage V1 of the battery pack;

[0078] (3) Disconnect the battery pack from the load, connect the voltage holding device and the battery pack to the input terminal of the differential amplifier at the same time, and connect the output terminal of the differential amplifier to the input terminal of the digital-to-analog converter, thereby obtaining Amplified high precision voltage difference.

[0079] The voltage maintaining device is a high insulation resistance capacitor, the insulation resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com