Honeycomb core structure design method for spherical robot cushioning shell

A design method and technology of honeycomb core, applied in design optimization/simulation, instrument, calculation, etc., can solve the requirements that limit the application of flat honeycomb core structure and cannot meet the requirements of a specific number of cells in the three-dimensional spherical honeycomb core layer, Shape distortion and other problems to achieve the effect of ensuring the characteristics of a positive sphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In this embodiment, the design goal is to design a spherical honeycomb core layer with a diameter of 240 mm, a core layer thickness of 20 mm, a cell wall thickness of 0.1 mm, and a cell side length of about 5 mm to 6 mm;

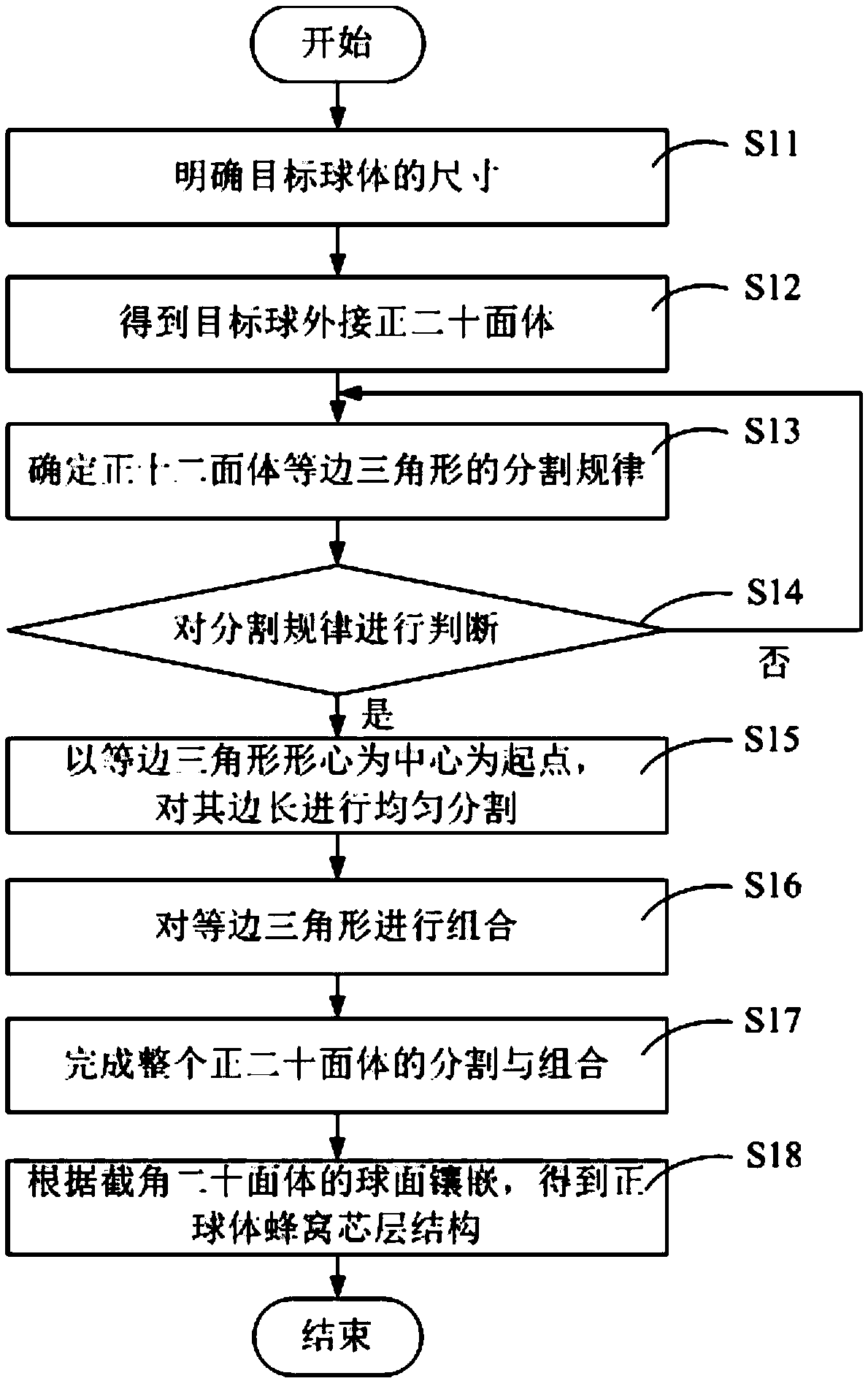

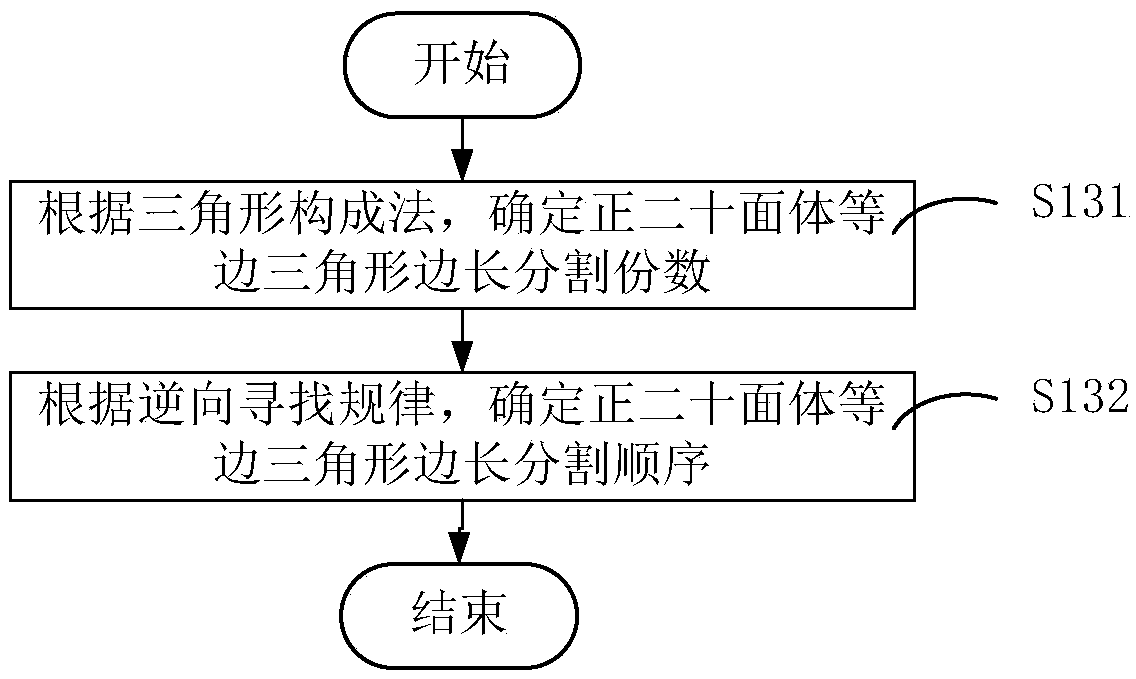

[0023] Such as figure 1 Shown spherical honeycomb core structure design method of the present invention, comprises the following steps:

[0024] Step S11, determine the radius r of the target sphere, and then draw the spherical surface of the target sphere; in this embodiment, r is 100mm;

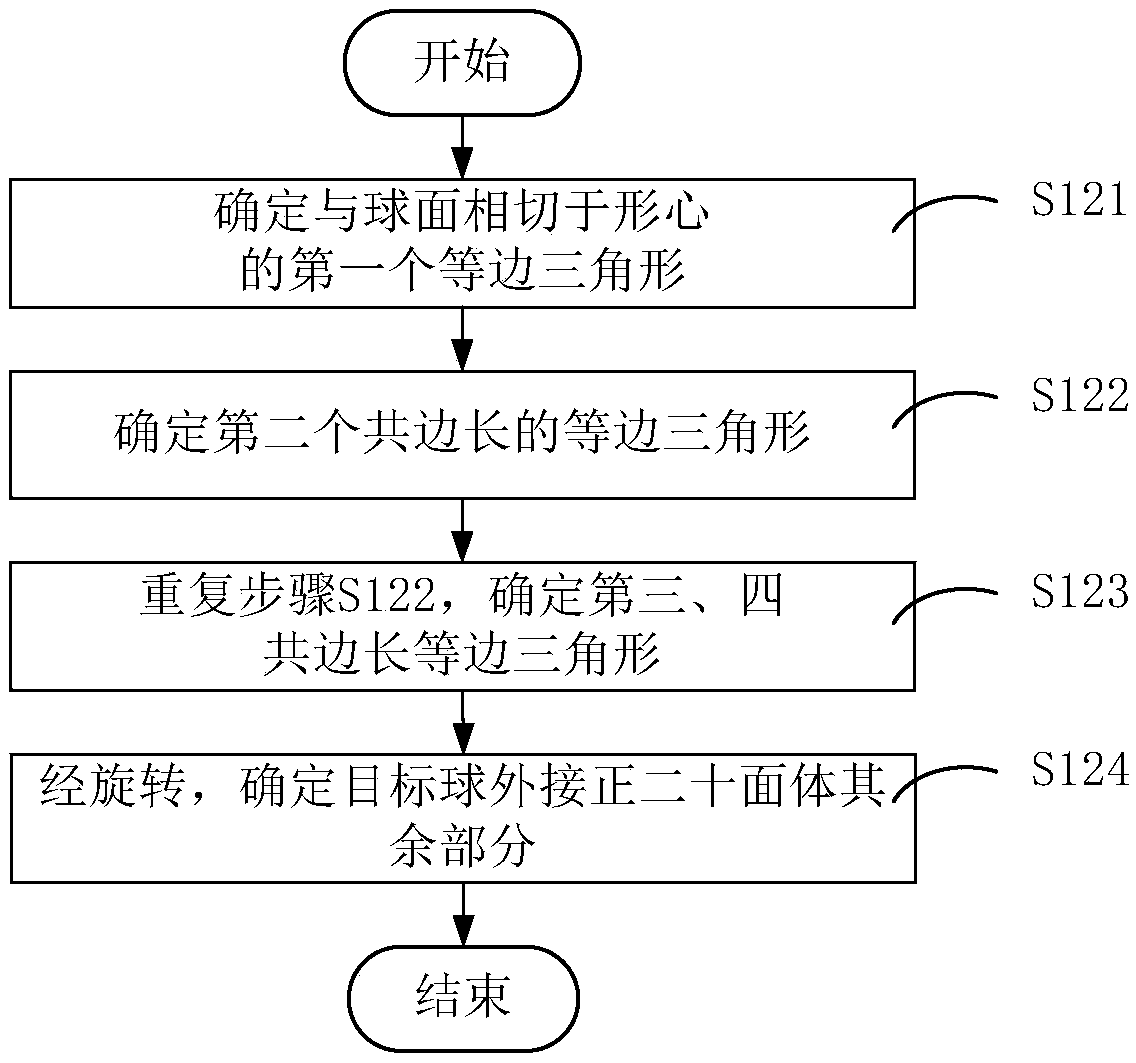

[0025] Step S12, according to the relationship between the size of the icosahedron and its inscribed sphere, determine the circumscribed icosahedron of the target sphere, the specific steps are as follows figure 2 shown, including:

[0026] Step S121, according to the formula

[0027]

[0028]

[0029] Determine the first equilateral triangle that satisfies the dimensional relationship requirements, and the equilateral triangle is tangent to the spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com