A self-damping low-loss high-corrosion resistant hard aluminum wire strand and a manufacturing method thereof

A manufacturing method and low-loss technology, which is applied in the manufacture of self-damping, low-loss, high-corrosion duralumin-shaped stranded wires, and in the field of self-damping, low-loss, high-corrosion-resistant duralumin-shaped stranded wires, can solve the problems of wire fatigue, broken strands, The whole wire breakage and other problems can be solved to reduce line loss, increase service life and reduce transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

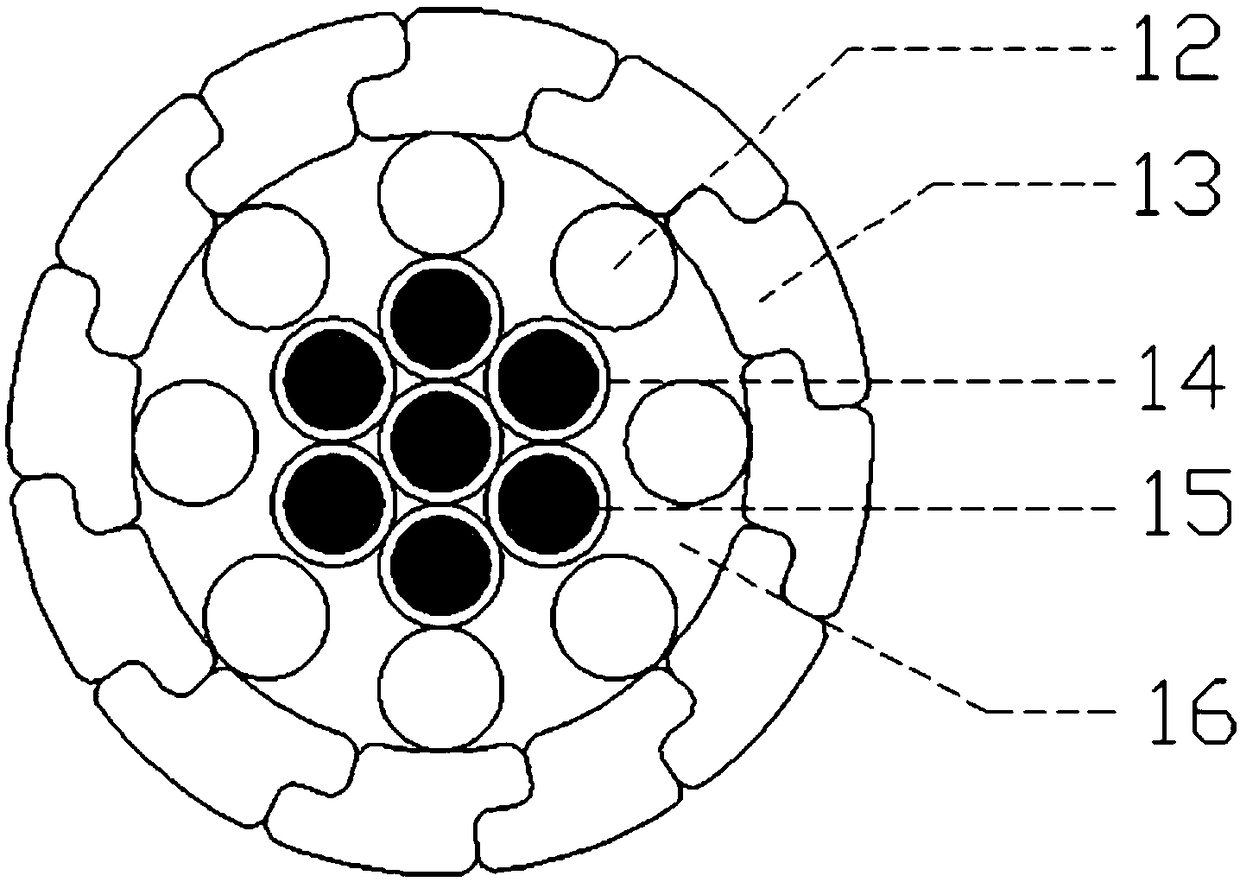

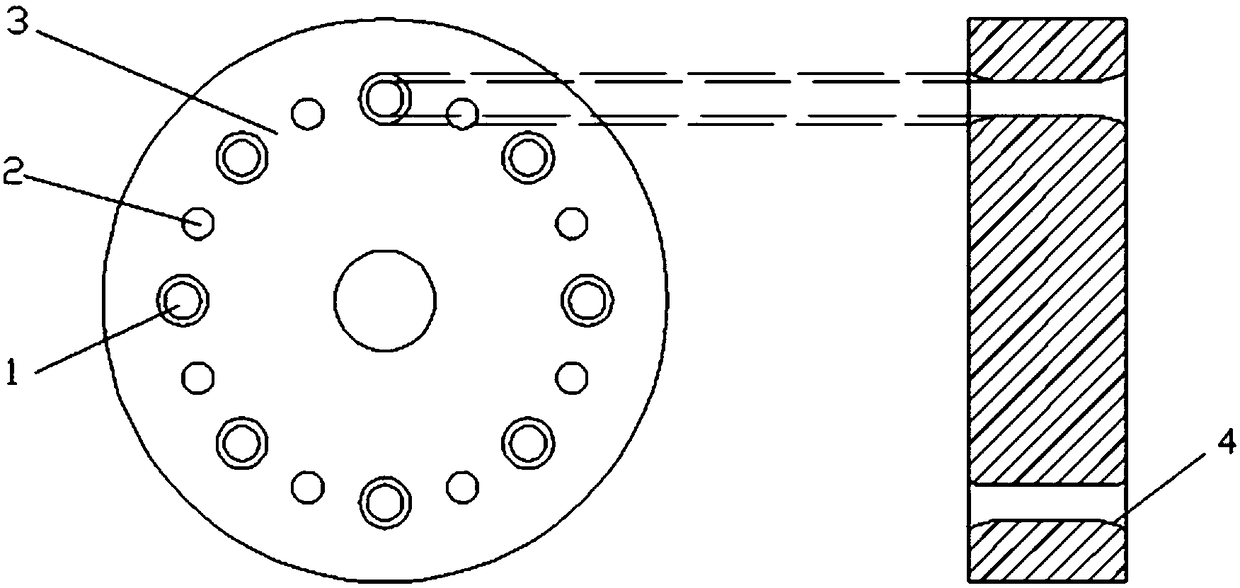

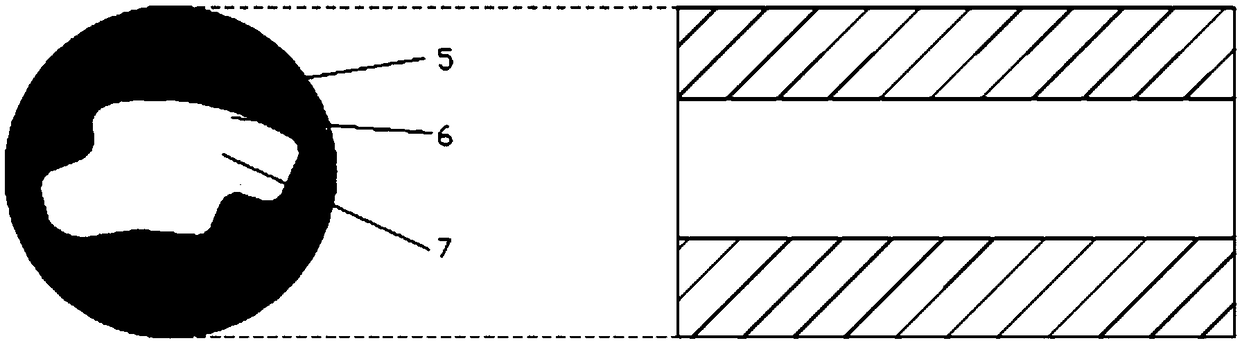

[0033] A self-damping, low-loss, high-corrosion hard aluminum type wire stranded wire, see figure 1 : It includes an inner core and an outer stranded layer. The outer stranded layer specifically includes an inner layer conductor and an outer layer conductor. The inner core is specifically a load-bearing reinforcement core formed by concentrically twisting zinc-5% aluminum-mixed coated steel wires. A layer of inner conductor layer consisting of N strands of 63% IACS conductive circular cross-section aluminum wire strands 12 is concentrically and tightly stranded outside the load-bearing reinforcing core, and at least one layer is concentrically stranded on the inner conductor layer and consists of several 63 %IACS Conductivity "SZ" type cross-section aluminum wire strands 13 closed outer conductor layer.

[0034] When the outer layer conductor is one layer, the twist direction of the outer layer conductor of a single layer is right, and the twist direction of the adjacent inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com