Preparation method of high coercive force magnet

A technology of high coercive force and magnets, applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., can solve the problems of reduced residual magnetism, heavy rare earth transition consumption, and increased production costs, so as to improve residual magnetism and hinder Effect of grain growth and coercivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-coercivity magnet, comprising the following steps:

[0035] Step 1, taking Nd-Fe-B powder and spraying nano-rare earth powder on its upper surface, and then alternately spraying Nd-Fe-B powder and nano-rare earth powder on the upper surface of nano-rare earth powder to obtain a layered mixture;

[0036] Step 2: pressing the layered mixture into a compact, and placing the compact in a vacuum heat treatment furnace for heat treatment to obtain a high coercivity magnet. The vacuum heating treatment process is a continuous grain boundary diffusion and grain boundary phase homogenization treatment process, and a stepwise heating method.

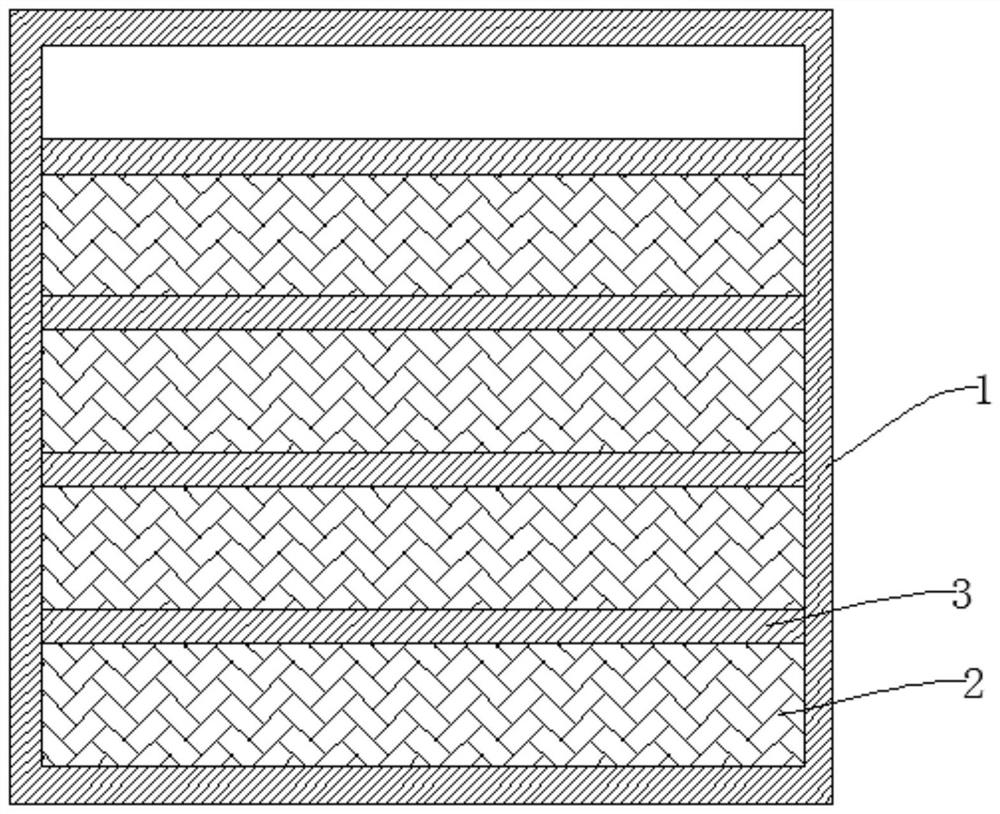

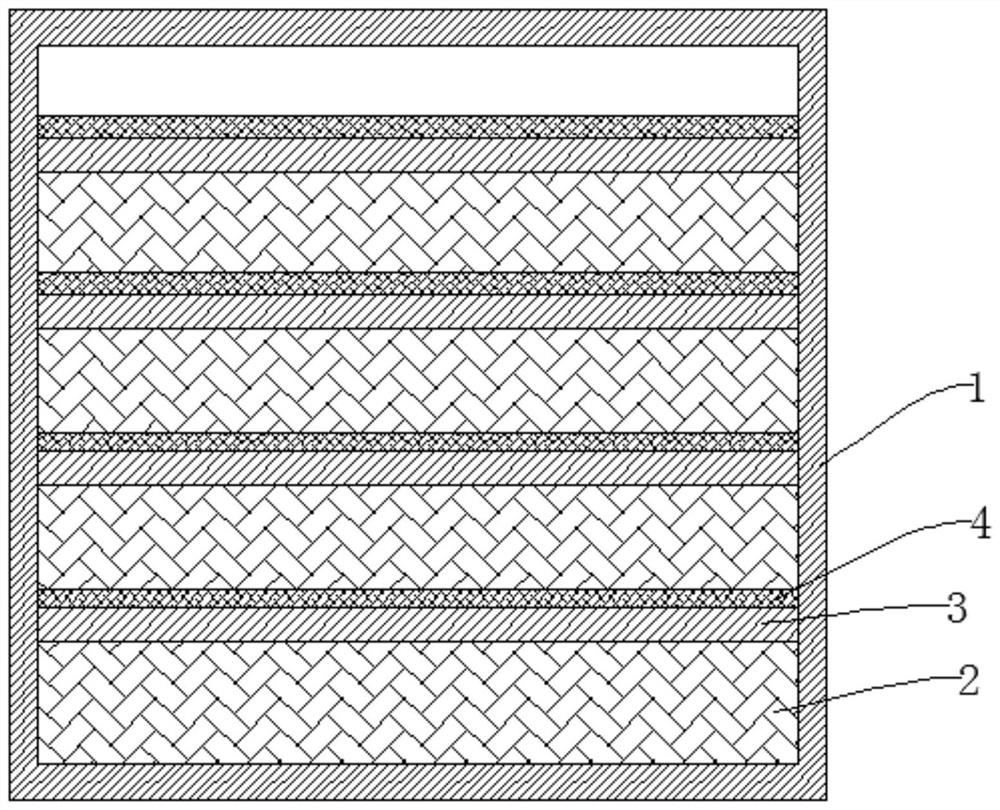

[0037] The preparation method of the high coercive force magnet of the present invention can obtain layered mixture by the powder distributing device 1 of existing full-automatic anaerobic press, as figure 1 As shown, the powder distributing device 1 is placed in a magnetic field, first arrange one deck of Nd-...

Embodiment 2

[0041] A method for preparing a high-coercivity magnet, comprising the following steps:

[0042] Step 1, take the Nd-Fe-B powder and spray nano-rare earth powder on its upper surface, then alternately spray Nd-Fe-B powder and nano-rare earth powder on the upper surface of the nano-rare earth powder to obtain a layered mixture; in this embodiment There are altogether 6 layers of Nd-Fe-B powder layer and nano-rare earth powder layer.

[0043] Step 2: pressing the layered mixture into a compact, and placing the compact in a vacuum heat treatment furnace for heat treatment to obtain a high coercivity magnet.

[0044] In the preparation method of the high-coercivity magnet, the nano rare earth powder is rare earth terbium, the mass fraction of Nd-Fe-B powder in the layered mixture is 99.6%, and the particle size of the Nd-Fe-B powder is 3 μm.

[0045] In the preparation method of the high coercive force magnet, the heat treatment in step 2 is specifically: evacuating the vacuum he...

Embodiment 3

[0048] Step 1, take the Nd-Fe-B powder and spray nano-rare earth powder on its upper surface, then alternately spray Nd-Fe-B powder and nano-rare earth powder on the upper surface of the nano-rare earth powder to obtain a layered mixture; in this embodiment There are altogether 6 layers of Nd-Fe-B powder layer and nano-rare earth powder layer.

[0049] Step 2: pressing the layered mixture into a compact, and placing the compact in a vacuum heat treatment furnace for heat treatment to obtain a high coercivity magnet.

[0050] In the preparation method of the high-coercivity magnet, the nano-rare earth powder is rare earth dysprosium-terbium alloy powder, the mass fraction of Nd-Fe-B powder in the layered mixture is 99.7%, and the particle size of Nd-Fe-B powder is 3.2 μm.

[0051] In the preparation method of the high coercive force magnet, the heat treatment in step 2 is specifically: evacuating the vacuum heat treatment furnace until the pressure is less than 7×10 -3 Pa, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com