Rare earth neodymium iron boron magnet grain boundary diffusion method

A rare earth neodymium iron boron and grain boundary diffusion technology, which is applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of magnet remanence decrease, manufacturing cost increase, heavy rare earth element consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

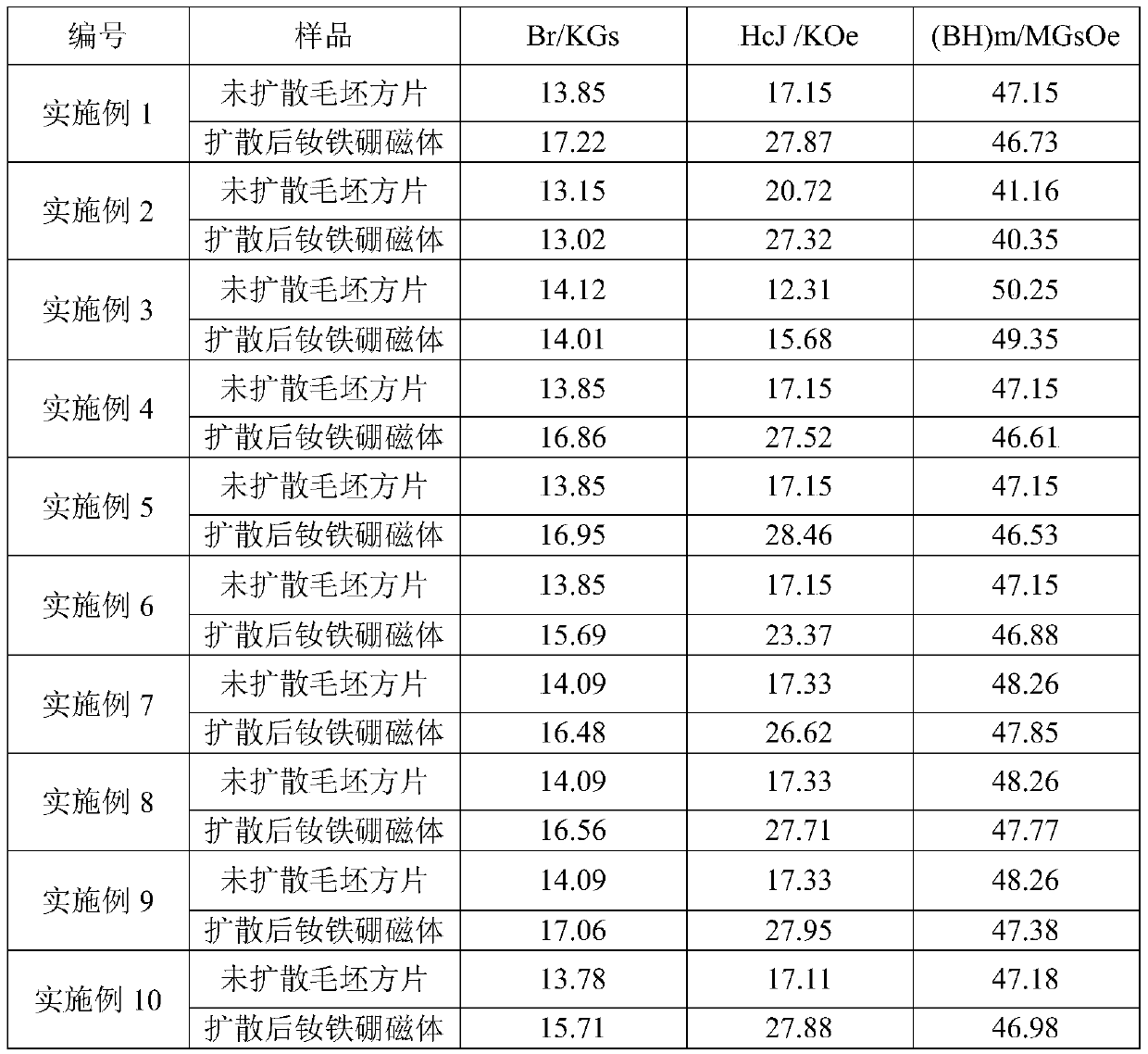

Examples

Embodiment 1

[0029] A rare earth NdFeB magnet grain boundary diffusion method, comprising the following steps:

[0030](1) prepare the RTM alloy cast sheet that thickness is 0.3mm through the vacuum quick-setting process according to the following formula: R is Tb, T is Fe, M is Al, and the mass percentages of Tb, Fe, Al in the powder are respectively 75%, 20% % and 5%;

[0031] (2) N48H NdFeB magnet blanks are prepared through smelting, powder making, molding, and sintering steps, and processed into blank square pieces with a size of 42×31×3mm (3mm is the orientation direction);

[0032] (3) Carry out surface activation to the rough square: put the rough square into a 20g / L degreasing aqueous solution with a temperature of 60°C for degreasing treatment for 3 minutes; then put the degreased rough square into 3% pickling in the nitric acid solution for 45s; finally put the pickled product in alcohol for 15s and then dry it;

[0033] (4) Lay the RTM alloy cast sheet on the bottom of the gr...

Embodiment 2

[0036] A rare earth NdFeB magnet grain boundary diffusion method, comprising the following steps:

[0037] (1) prepare the RTM alloy cast sheet that thickness is 0.28mm through the vacuum quick-setting process according to the following formula: R is Dy, T is Co, and M is Cu; The mass percents of Dy, Co, Cu are respectively 80%, 5% in the powder % and 5%;

[0038] (2) N42SH NdFeB magnet blanks are prepared through smelting, powder making, molding, and sintering steps, and processed into blank square pieces with a size of 50×20×4mm (4mm is the orientation direction);

[0039] (3) Carry out surface activation to the rough square: put the rough square into a 25g / L degreasing aqueous solution with a temperature of 60°C for degreasing for 3.5 minutes; then put the degreased rough into 3.5% pickling in nitric acid solution for 50s; finally put the pickled product in alcohol for 18s and then dry it;

[0040] (4) Lay the RTM alloy cast sheet on the bottom of the graphite box, and th...

Embodiment 3

[0043] A rare earth NdFeB magnet grain boundary diffusion method, comprising the following steps:

[0044] (1) Prepare the RTM alloy cast sheet that thickness is 0.32mm through the vacuum quick-setting process according to the following formula: R is Nd, T is Co, and M is Al; the mass percentages of Nd, Co, and Cu are respectively 75%, 15% in the powder % and 10%;

[0045] (2) N50 NdFeB magnet blanks are prepared through smelting, powder making, molding, and sintering steps, and processed into blank square pieces with a size of 50×20×2.5mm (2.5mm is the orientation direction);

[0046] (3) Carry out surface activation to the rough square: put the rough square into a 26g / L degreasing aqueous solution with a temperature of 65°C for degreasing treatment for 4 minutes; then put the degreased rough square into 3.6% pickling in nitric acid solution for 45s; finally put the pickled product in alcohol for 16s and then dry it;

[0047] (4) Lay the RTM alloy cast sheet on the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com