A self-powered power supply circuit for a flyback power converter

A technology of self-sufficient power supply and flyback power supply, which is applied to emergency protection circuit devices, conversion of AC power input to DC power output, electrical components, etc., and can solve the problems of burning control chips, large bus voltage ripple, and large voltage ripple. , to achieve easy layout and wiring, improve reliability, and increase reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

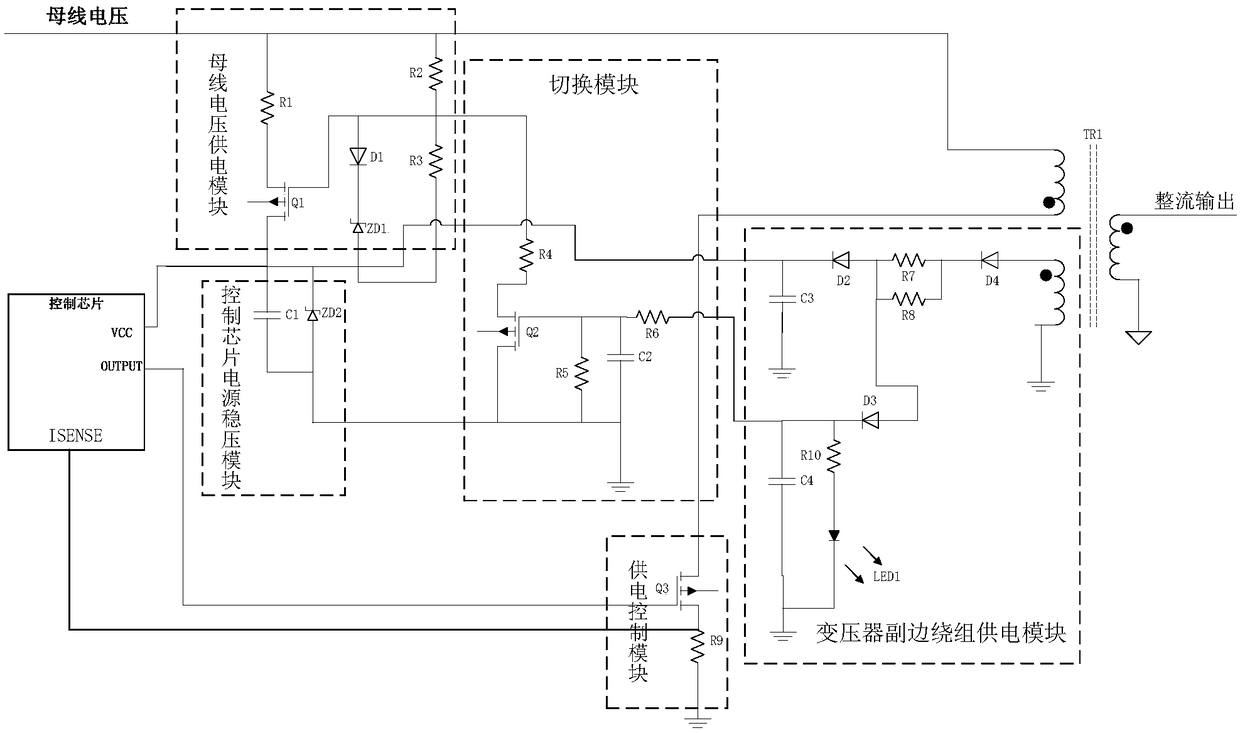

[0024] The self-sufficient power supply circuit is composed of a bus voltage power supply module, a secondary winding power supply module of a transformer, a voltage stabilizing module controlling a chip power supply, a transformer, a power supply control module and a switching module. The bus voltage power supply module supplies power to the control chip after the bus is powered on; after the control chip is powered on, it controls the operation of the primary winding of the transformer through the power supply control module, and rectifies and outputs electric energy through the secondary output winding; the secondary auxiliary winding of the transformer is coupled from the primary winding The voltage is obtained to supply power to the power supply module of the secondary winding of the transformer; the power supply module of the secondary winding of the transformer includes a first charging unit, a second charging unit and a switch unit, and the power supply module of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com