Variable frequency step-down motor economizer

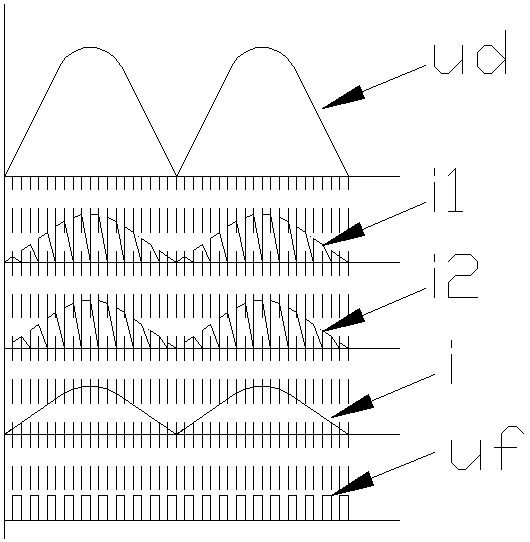

A technology for motors and power savers, which is applied in the direction of AC motor control, electrical components, and harmonic reduction devices. Low subharmonic components, continuous current waveform, and the effect of reducing terminal voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1 (applied to single-phase motor):

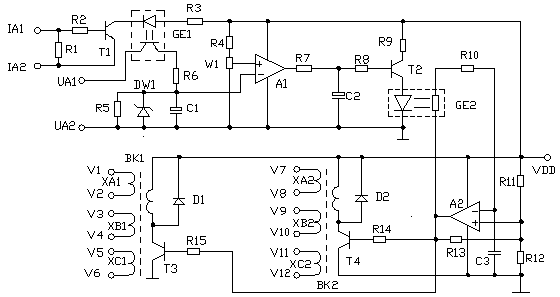

[0012] A frequency conversion step-down motor saver, which includes a main circuit and a frequency conversion control circuit, the main circuit includes an A-phase voltage regulation circuit, the A-phase voltage regulation circuit includes a full-wave rectifier QLA, the input terminal of the full-wave rectifier QLA is connected to the A-phase of the motor The phase windings are connected in series, the positive pole of the output terminal of the full-wave rectifier QLA is connected to the collector of the transistor TA1 through the inductor LA1, the emitter of the transistor TA1 is connected to the negative pole of the output terminal of the full-wave rectifier QLA, and the positive pole of the output terminal of the full-wave rectifier QLA is connected to the collector of the transistor TA2 through the inductor LA2 The electrode, the emitter of the triode TA2 is connected to the negative pole of the output end of the full-...

no. 2 example

[0023] Second embodiment (applied to three-phase motors in delta or star connection):

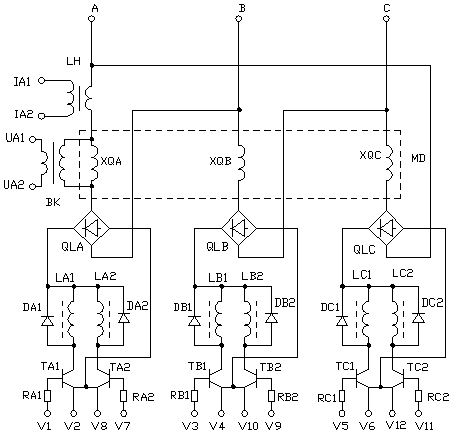

[0024] The delta connection method of the winding of the three-phase motor MD is as follows: figure 1 As shown, the first end of the A-phase winding XQA is connected to the A-phase power supply, the first end of the B-phase winding XQB is connected to the B-phase power supply, the first end of the C-phase winding XQC is connected to the C-phase power supply, and the tail end of the A-phase winding XQA is connected to the B-phase winding The head end of XQB, the tail end of the B-phase winding XQB is connected to the head end of the C-phase winding XQC, and the tail end of the C-phase winding XQC is connected to the head end of the A-phase winding XQA. One of the differences from the first embodiment is that the main circuit includes an A-phase voltage regulating circuit, a B-phase voltage regulating circuit, and a C-phase voltage regulating circuit. The A-phase voltage regulating circuit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com