Device for discharging multi-component adhesives onto a granular mixture, discharging method, and use of the device

An adhesive, multi-component technology for application in jetting, jetting, shipping and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

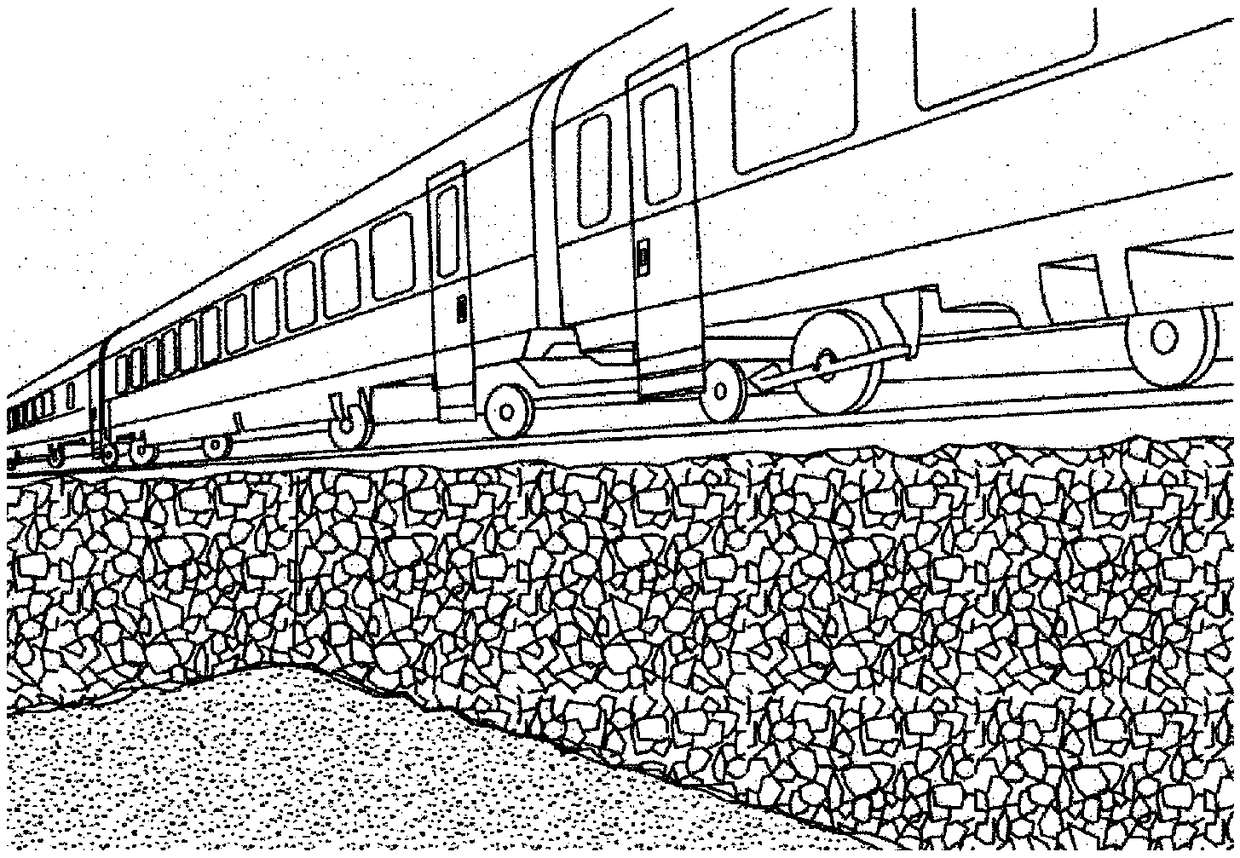

[0034] figure 1 One application is shown, namely longitudinally cut ballasted tracks just outside rail sections, which were previously bonded by spraying two-component epoxy resin so that they form quasi-monomeric blocks. In this state, the ballasted road can be removed by excavating the shovel, as shown here, but it remains stable so that the vertical walls can be cleared without the ballasted track significantly losing its load-bearing strength and stability. Ballast. Whenever e.g. cables or pipes have to be laid along such a rail section, there are serious problems with maintaining the stability of the rail track if trains run continuously on it (i.e. during installation work on the pipeline or pipe) . Where routine stabilization is not possible, track sections will have to be closed for rail traffic, which will mean severe restrictions and costly downtime for rail operators.

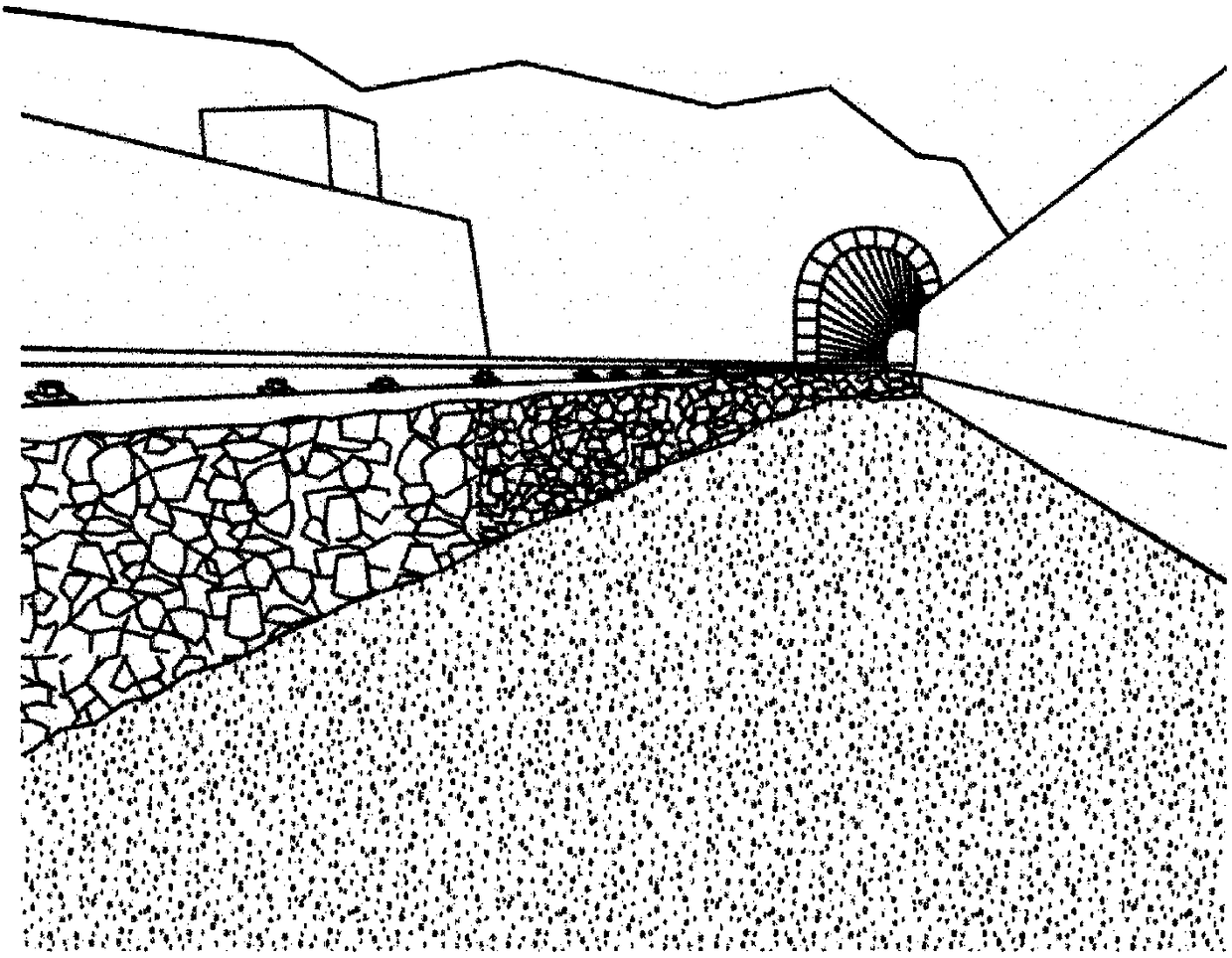

[0035] figure 2 Another ballasted track is shown, which is stabilized by gluing and then cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com