Sacrificial electrode type arc welding method

An arc welding method and technology for consuming electrodes, which are applied to arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of arc interruption and difficulty in ensuring the stability of the starting part, so as to prevent arc interruption, shorten the transition time, and ensure fusion. depth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

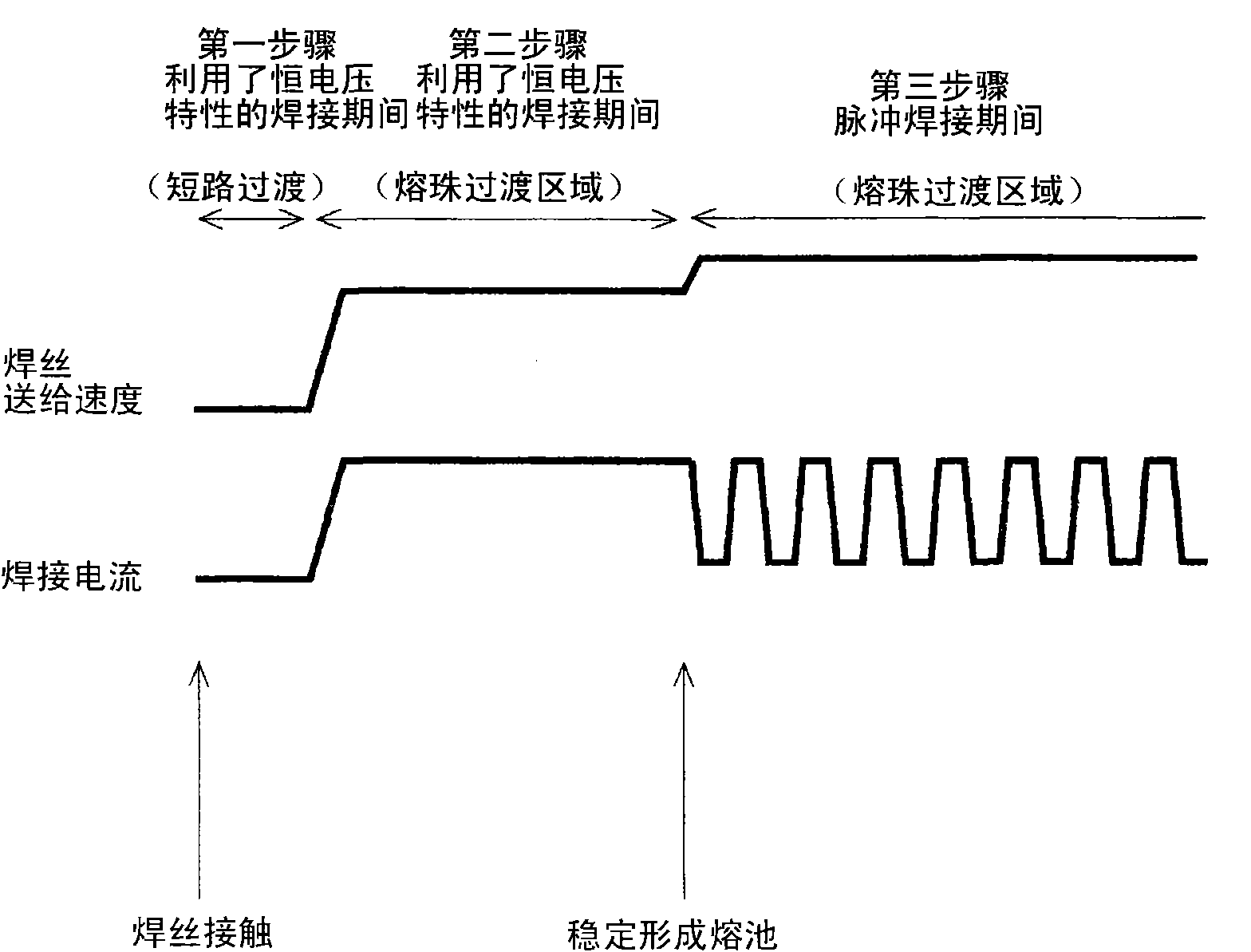

[0021] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. This embodiment is an automatic welding method based on consumable electrode arc welding using carbon dioxide. figure 1 It is a graph showing the time course of the welding current and the feeding speed of the welding wire in the consumable electrode type arc welding method according to the embodiment of the present invention. The horizontal axis is time, and the vertical axis is the feeding speed and welding current, showing the time course .

[0022] First, in a first step, the arc is initiated by the contact of the welding wire. This first step is welding with a constant voltage characteristic, with a relatively low current value, forming an arc during the short circuit transition. For example, the welding current in the first step is 100-200A, the arc voltage is 15-27V, and the duration of the arc after starting is a minute time of 0.1-1.0 second.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com