Pipe internally inlaid with welding flux and welding technology

A welding process and pipe fitting technology, which is applied to the field of inlaid solder-type pipe fittings and welding processes, can solve the problems of inability to achieve results, unsatisfactory welding quality, and high technical requirements of operators, so as to ensure penetration depth and firmness, reduce welding difficulty, Good flow uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

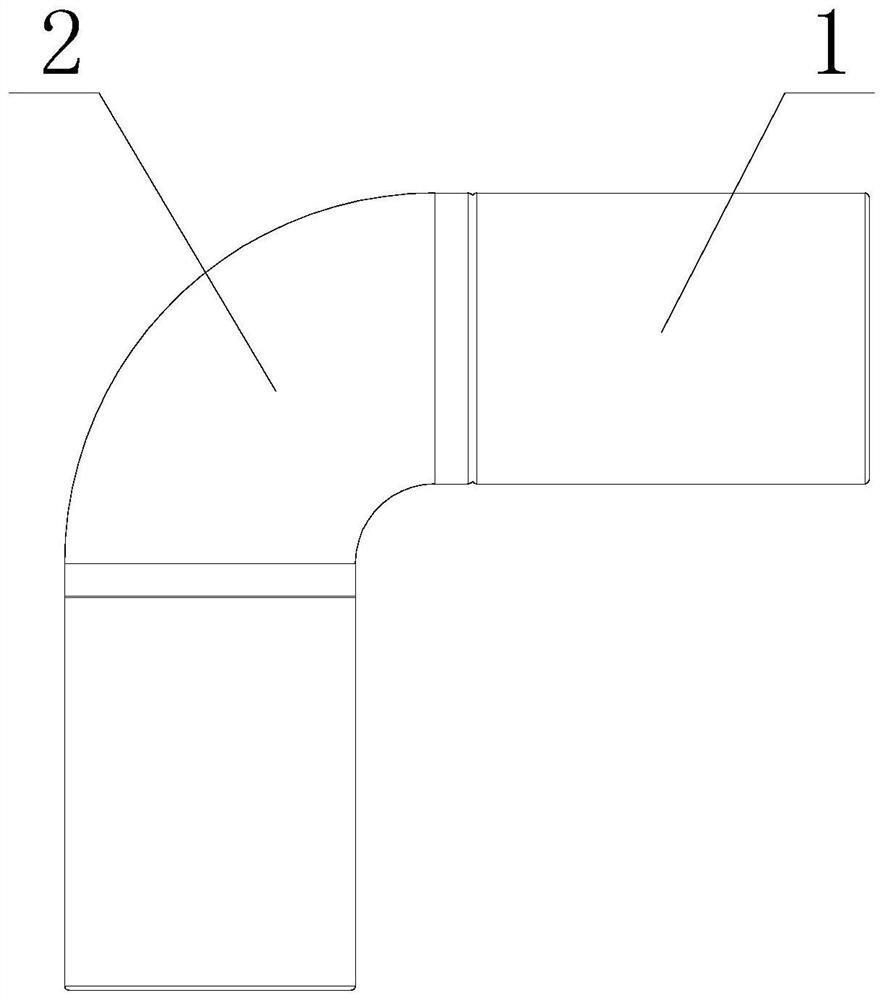

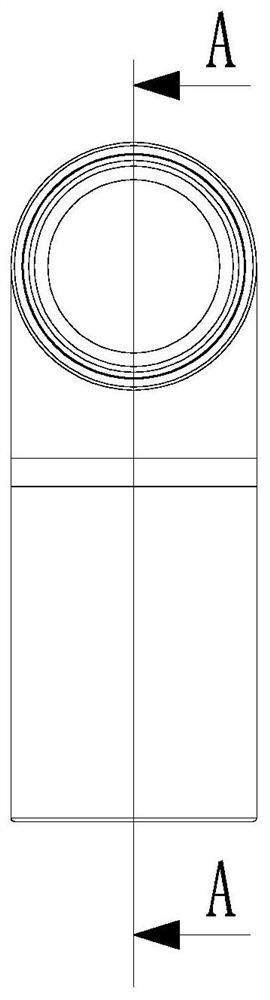

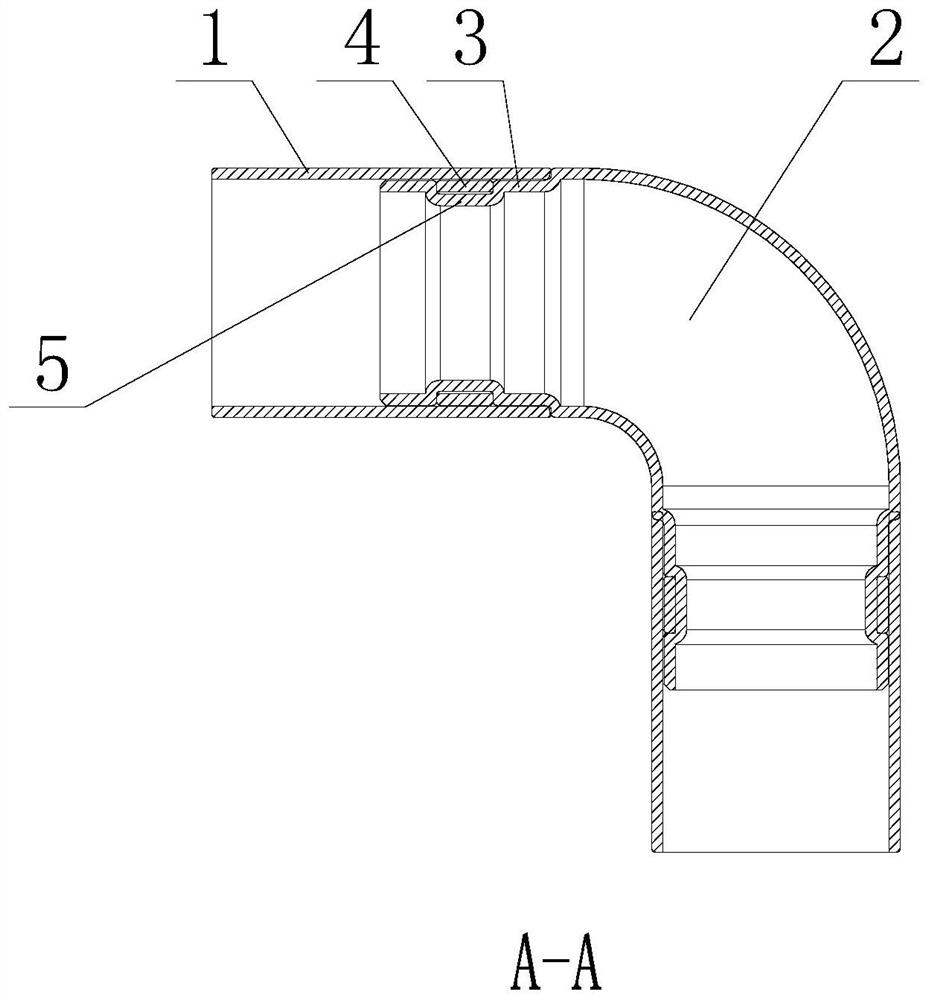

[0033] like Figure 1-3 shown, solder-inset fittings, including

[0034] The pieces to be connected include a first pipe and a second pipe;

[0035] The connection part, which includes the inner extension part where the first pipe piece and the second pipe piece are inserted and overlapped, a section of the inner extension part is deformed outwardly or inwardly to form an annular groove, and the position of the annular groove is inwardly extended between the inner side of the head and the undeformed fitting for placement of solder.

[0036] In this embodiment, the inward extension is the overlapping portion of the first pipe and the second pipe. If the first pipe is on the outside, the inward extension is a part of the second pipe. If the second pipe is on the outside, the inward extension It is a part of the first pipe, and the inner extension is provided with an annular groove, and the annular groove is formed so that the inner extension protrudes outward or inward, for ex...

Embodiment 2

[0038] The annular groove is arranged on the second pipe member and has a concave structure.

[0039] like image 3 As shown, in this embodiment, if the annular groove is on the second pipe member, the annular groove needs to be recessed, and solder can be placed in the recessed annular groove.

Embodiment 3

[0041] The annular groove is arranged on the first pipe member and has an outwardly convex structure.

[0042] like Figure 4 As shown, in this embodiment, if the annular groove is on the first pipe member, the annular groove needs to be convex, and solder can be placed in the convex annular groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com