Preparation of matt paints and printing inks

A technology for inorganic pigments and coating preparations, applied in the field of matte substrates, coating preparations, and the preparation of the pigment composition, can solve the problems of the degree of extinction and the like, and achieve the effects of easy preparation, easy handling and application, and good extinction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

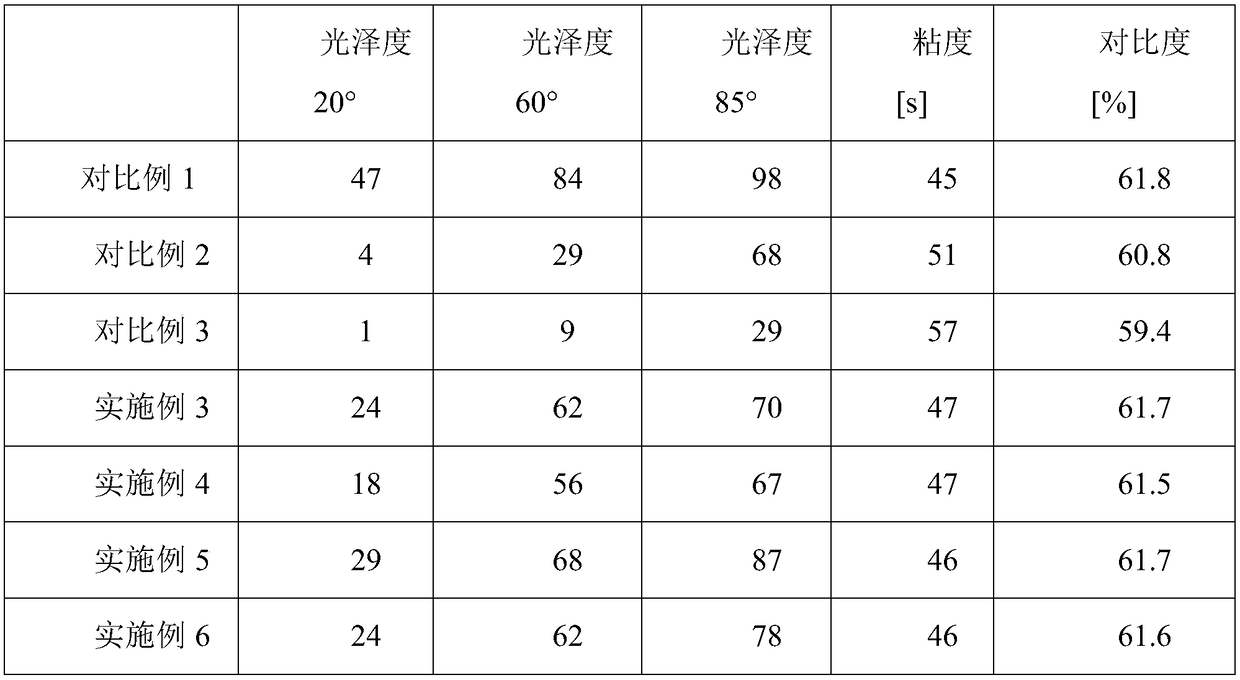

Examples

Embodiment 1a

[0059] Coarse-grained, non-pigmentary titanium dioxide is sintered in a kiln. The sintered material (220 g) was ground and classified for particle size by sedimentation technique (Atterberg sedimentation). The agglomerates obtained had a particle size d50m of 17 (+ / - 2) μm. The component is post-treated with an aluminum oxide layer. Similar to the white pigment used, the amount of aluminum oxide was used to calculate similar layer thicknesses.

Embodiment 1b

[0061] Embodiment 1b includes the preparation of Example 1a, except that no work-up is carried out.

Embodiment 2

[0063] The standard formulation is based on nitrocellulose supplied in chip form, dissolved in ethanol and ethyl acetate. Other ingredients are plasticizers, and additives to improve the surface and gloss. After the vehicle was prepared and weighed in the pigment composition, the formulation was dispersed in a Skandex disperser using milling beads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com