Grease composition and sliding member

A grease composition and polymer technology, applied in the fields of mechanical devices and parts, can solve the problems of muteness and insufficient lubricating performance of the grease composition, and achieve the effects of excellent damping characteristics, excellent lubricating performance and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

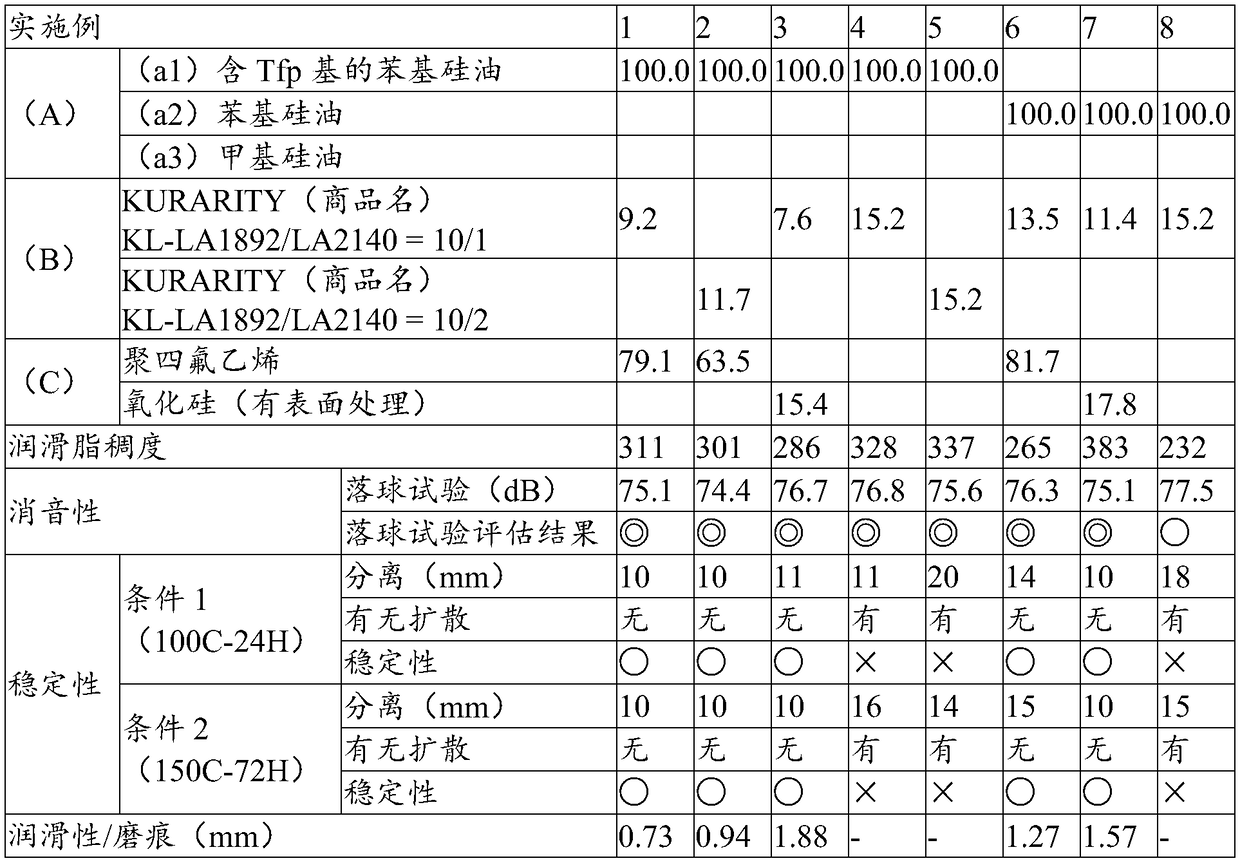

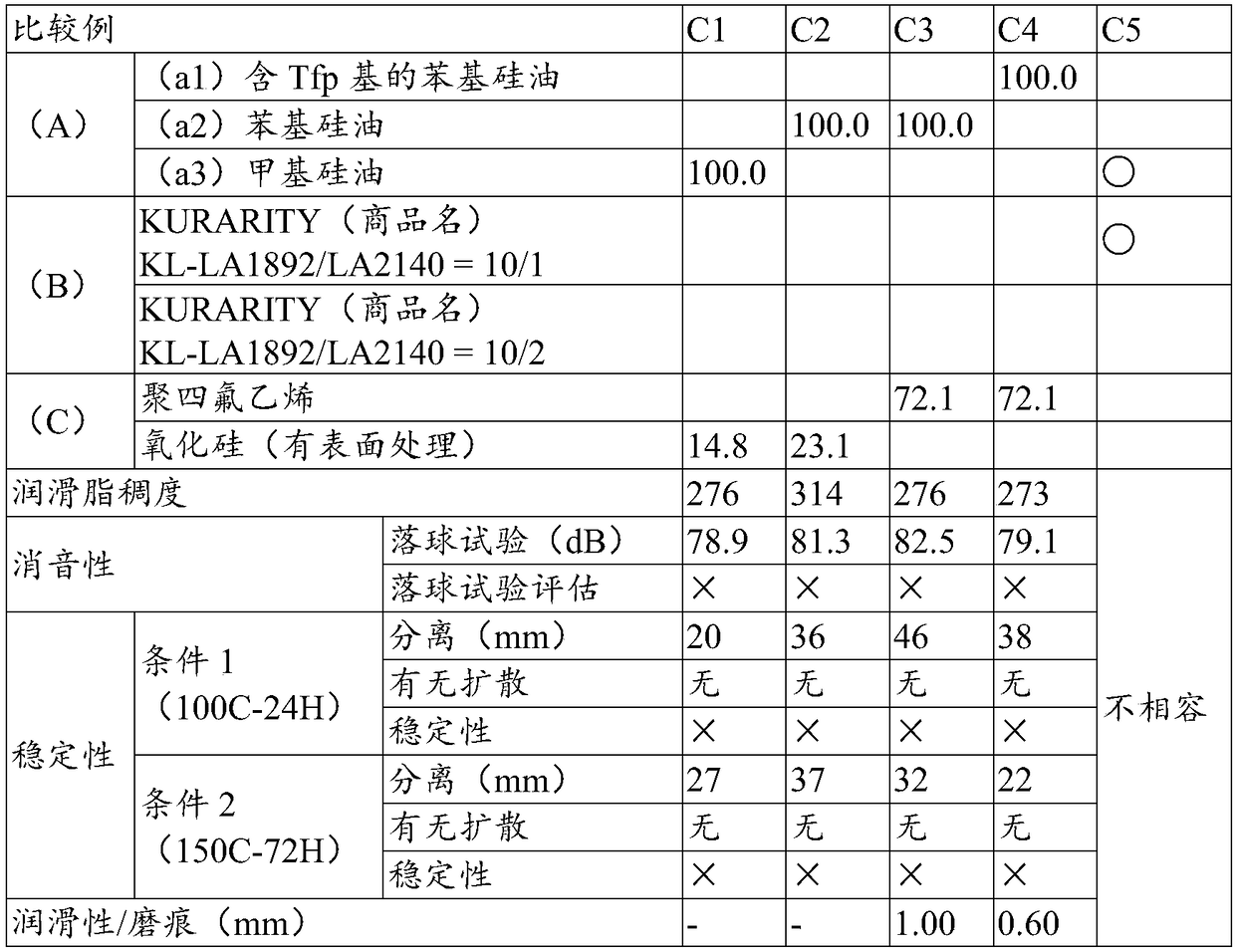

Embodiment 1~8 and comparative example C1~C5

[0093] Mix the components according to the ratio shown in Table 1 to Table 2. First, dissolve component B in toluene, and then mix the toluene solution of B and oil A evenly. A homogeneous mixture of A and B was prepared by evaporating toluene in an oven. Add solid powder C to the mixture of A and B, mix with a dental mixer, process with three rolling mills, and use a dental mixer for defoaming, so as to obtain the grease compositions of Examples 1-8 and Comparative Examples C1-C5 . In addition, the numerical value shown in Table 1 and Table 2 represents a mass part. In addition, grease compositions could not be prepared when the ingredients were incompatible during the mixing stage, as noted in the table. Specifically, in Comparative Example C5, the methyl silicone oil was not compatible with any of the (B) components, and a grease composition could not be prepared.

[0094] In Tables 1 to 2, each component is as follows. In addition, in component (a1), "Tfp group" refers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com