starter

A starter and center support technology, applied to engine components, engine starting, machine/engine, etc., can solve problems such as load transfer without considering load transfer, achieve the effect of improving reliability and suppressing noise diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

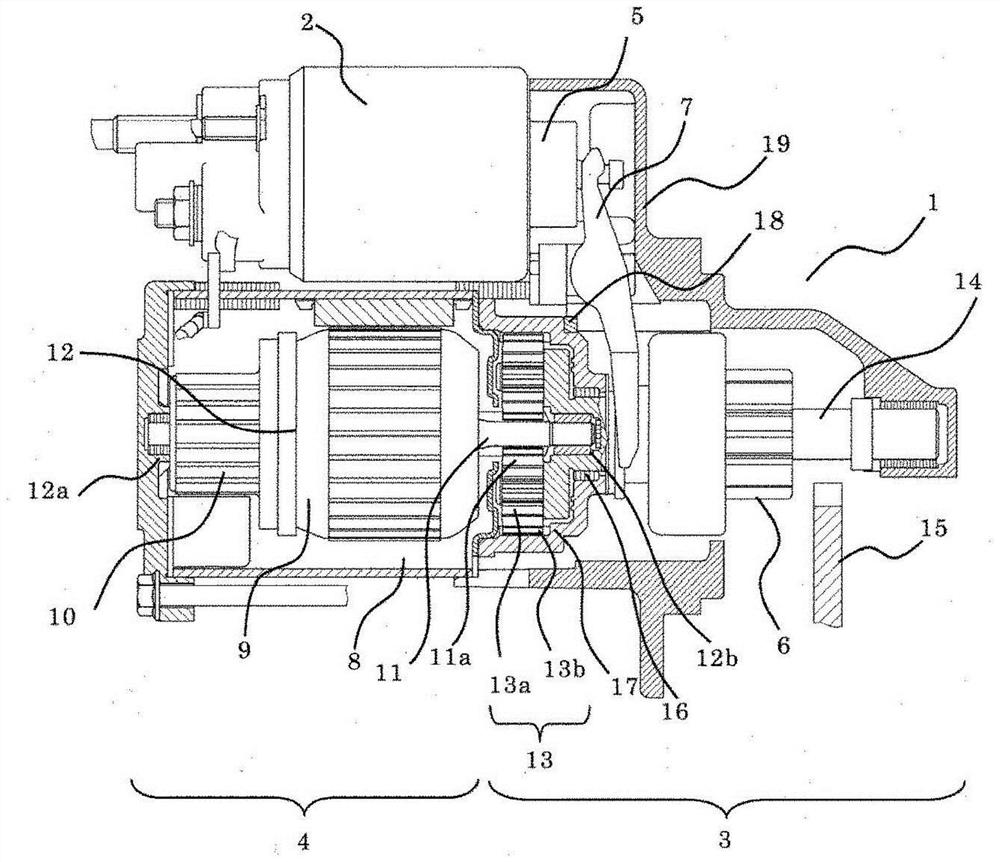

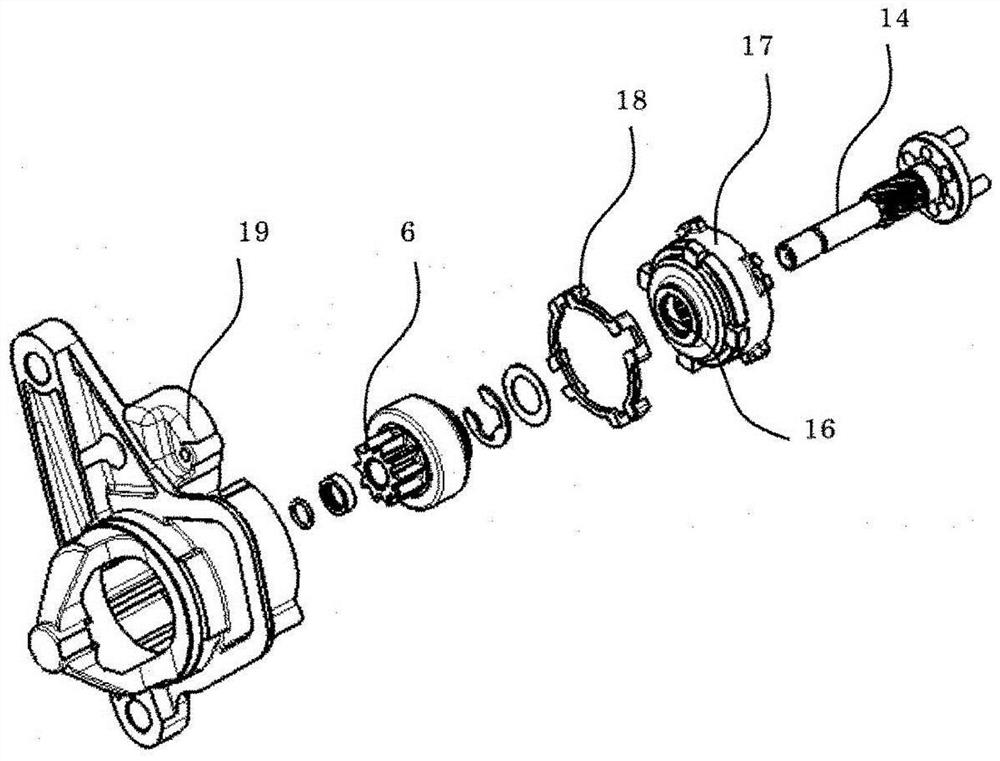

[0021] The starter 1 is composed of a magnetic switch 2 , a power transmission unit 3 and a motor 4 . When the current flows from the battery to the excitation coil housed inside the magnetic switch 2, the plunger 5 is attracted, and the pinion 6 housed in the power transmission part 3 is shifted via the shift rod 7 to face the motor mounted on the engine. The ring gear 15 moves in the axial direction, and the pinion gear 6 meshes with the ring gear 15 .

[0022] The motor 4 is composed of a laminated iron core 8 , a coil 9 , a commutator 10 , a shaft 11 , and an armature 12 . The armature 12 is rotatably mounted on slide bearings 12a, 12b. The external teeth 11a are formed on the top end of the shaft 11 and mesh with the planetary gears 13a of the planetary gear reduction mechanism 13 inside the power transmission part 3, so that the rotational force of the motor 4 is transmitted to the pinion shaft 14 at a prescribed reduction ratio, and rotates through the pinion shaft 14....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com