Casting technology of improved vehicle box body

A casting process and improved technology, applied in the field of aluminum alloy casting, can solve the problems of poor air tightness, air holes, unclear contours, etc., and achieve the effect of reducing the scrap rate, accurate positioning, and not easy to link and dislocate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

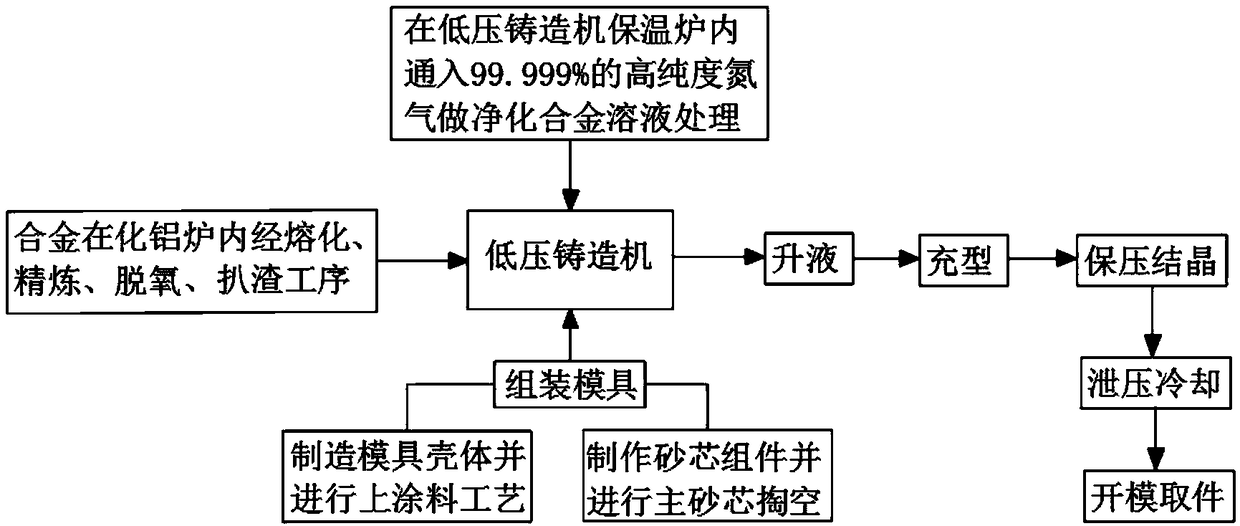

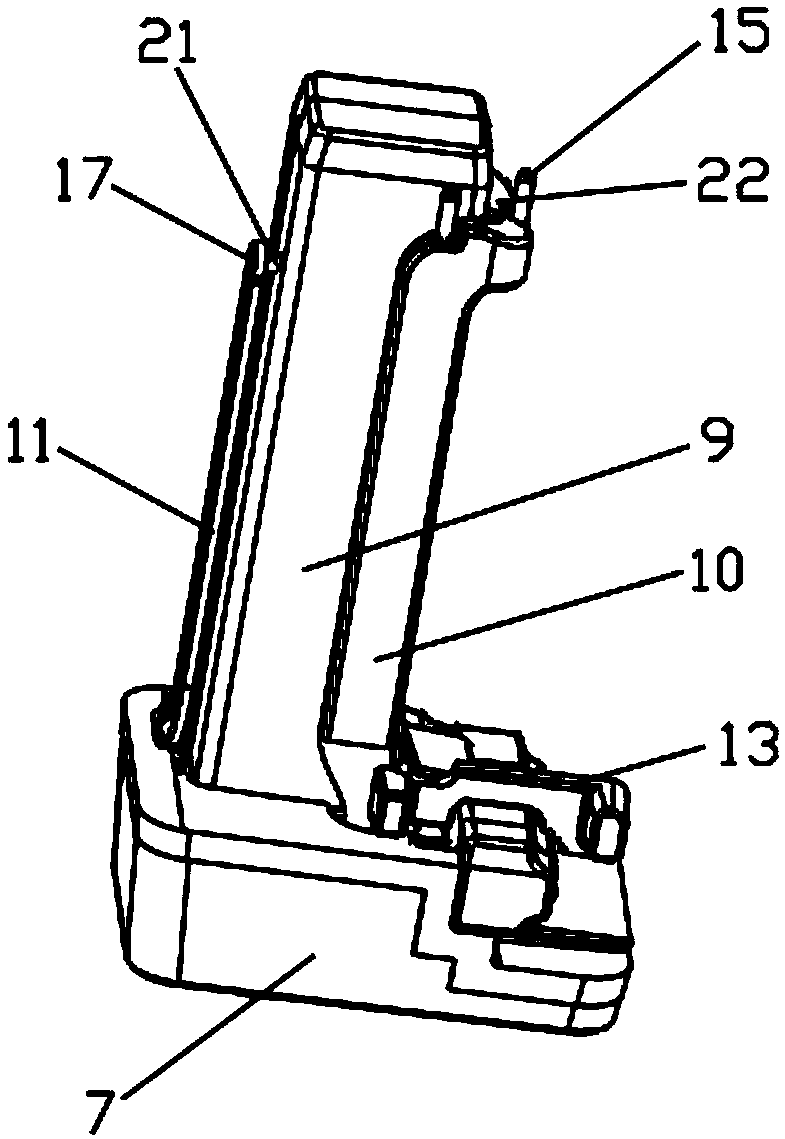

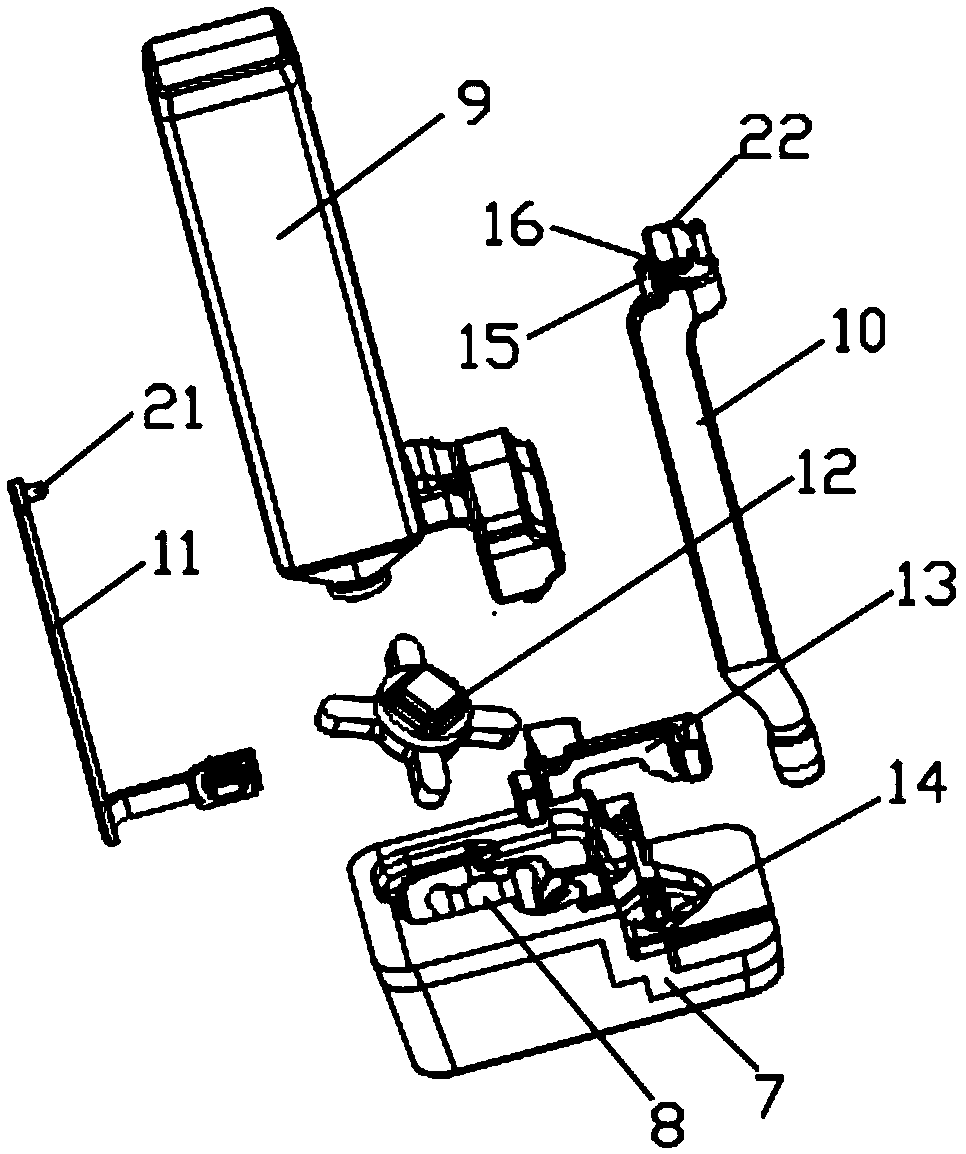

[0045] Please refer to Figure 1 to Figure 5 As shown, this embodiment provides a casting process for an improved vehicle box, including the following process steps:

[0046] (a) Making sand core components, using resin sand according to the shape of the vehicle exhaust gas treatment box to produce a block sand core component, the block sand core component includes a main sand core 9, a channel sand core 10, and a small channel sand Core 11, strap sand core 13 and cross sand core 12; make the main sand core 9 and channel sand core 10 assembly mold, small channel sand core 11 and strap sand core 13 assembly mold, and cross sand core 12 mold, and then cover The film sand is injected into the core mold, the temperature of the core mold is 270℃, the injection pressure is 0.7Mpa, and the shooting time is 10s; then the main sand core 9 is hollowed out, and the side wall of the main sand core 9 is hollowed out The solidification depth of the sand core is 18mm; the surface of the block-...

Embodiment 2

[0063] Please refer to Figure 1 to Figure 5 As shown, this embodiment provides a casting process for an improved vehicle box, including the following process steps:

[0064] (a) Making sand core components, using resin sand according to the shape of the vehicle exhaust gas treatment box to produce a block sand core component, the block sand core component includes a main sand core 9, a channel sand core 10, and a small channel sand Core 11, strap sand core 13 and cross sand core 12; make the main sand core 9 and channel sand core 10 assembly mold, small channel sand core 11 and strap sand core 13 assembly mold, and cross sand core 12 mold, and then cover The film sand is injected into the core mold, the temperature of the core mold is 280℃, the injection pressure is 0.6Mpa, and the injection time is 8s; then the main sand core 9 is hollowed out, and the side wall of the main sand core 9 is hollowed out The solidification depth of the sand core is 15mm; the surface of the block ...

Embodiment 3

[0081] Please refer to Figure 1 to Figure 5 As shown, this embodiment provides a casting process for an improved vehicle box, including the following process steps:

[0082] (a) Making sand core components, using resin sand according to the shape of the vehicle exhaust gas treatment box to produce a block sand core component, the block sand core component includes a main sand core 9, a channel sand core 10, and a small channel sand Core 11, strap sand core 13 and cross sand core 12; make the main sand core 9 and channel sand core 10 assembly mold, small channel sand core 11 and strap sand core 13 assembly mold, and cross sand core 12 mold, and then cover The film sand is injected into the core mold, the temperature of the core mold is 250℃, the injection pressure is 0.5Mpa, and the injection time is 8s; then the main sand core 9 is hollowed out, and the side wall of the main sand core 9 is hollowed out The solidification depth of the sand core is 20mm; the surface of the block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com