Robot automatic gouging welding steel ring workstation and using method thereof

A technology of robots and workstations, applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effect of good product consistency, convenient operation, and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

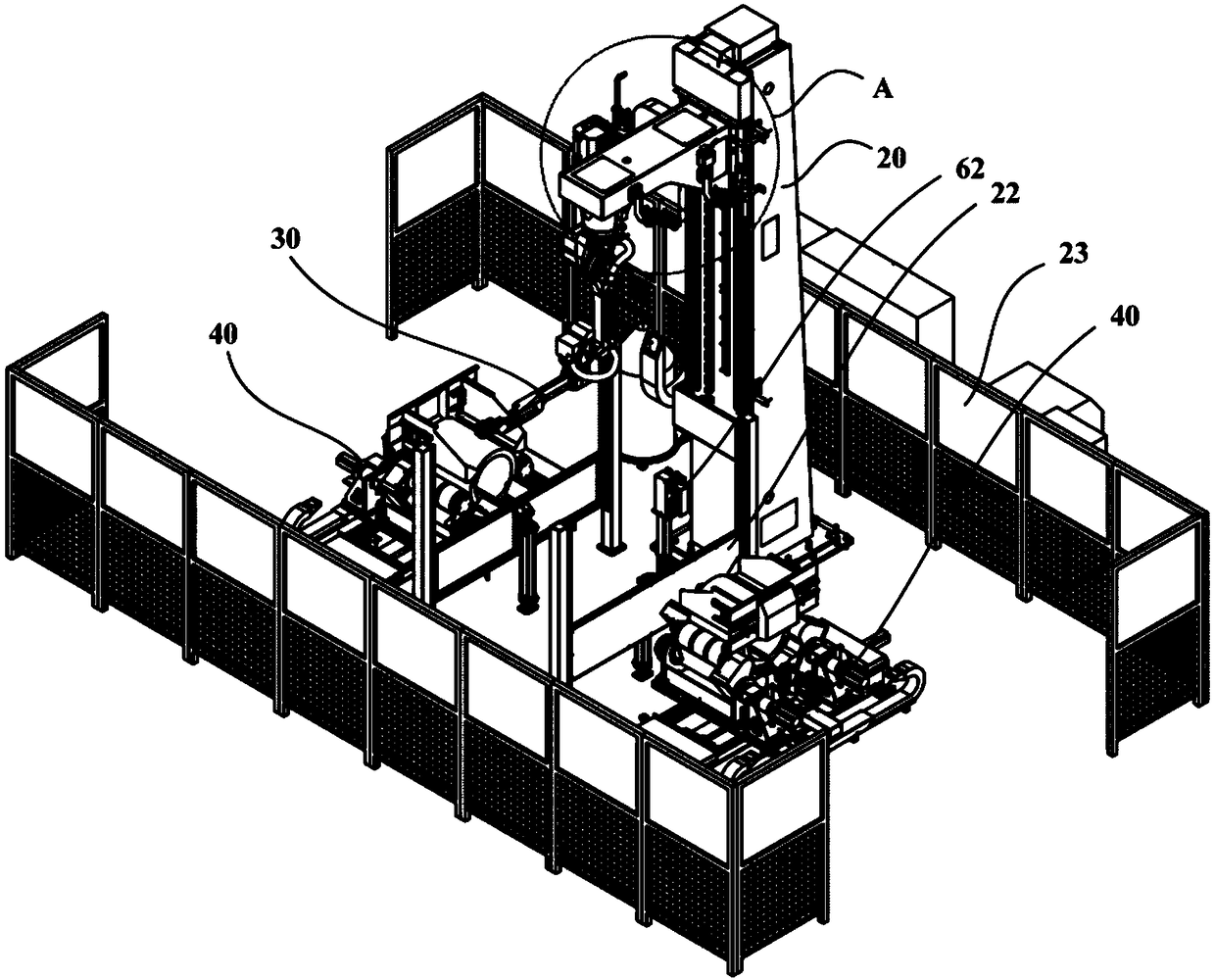

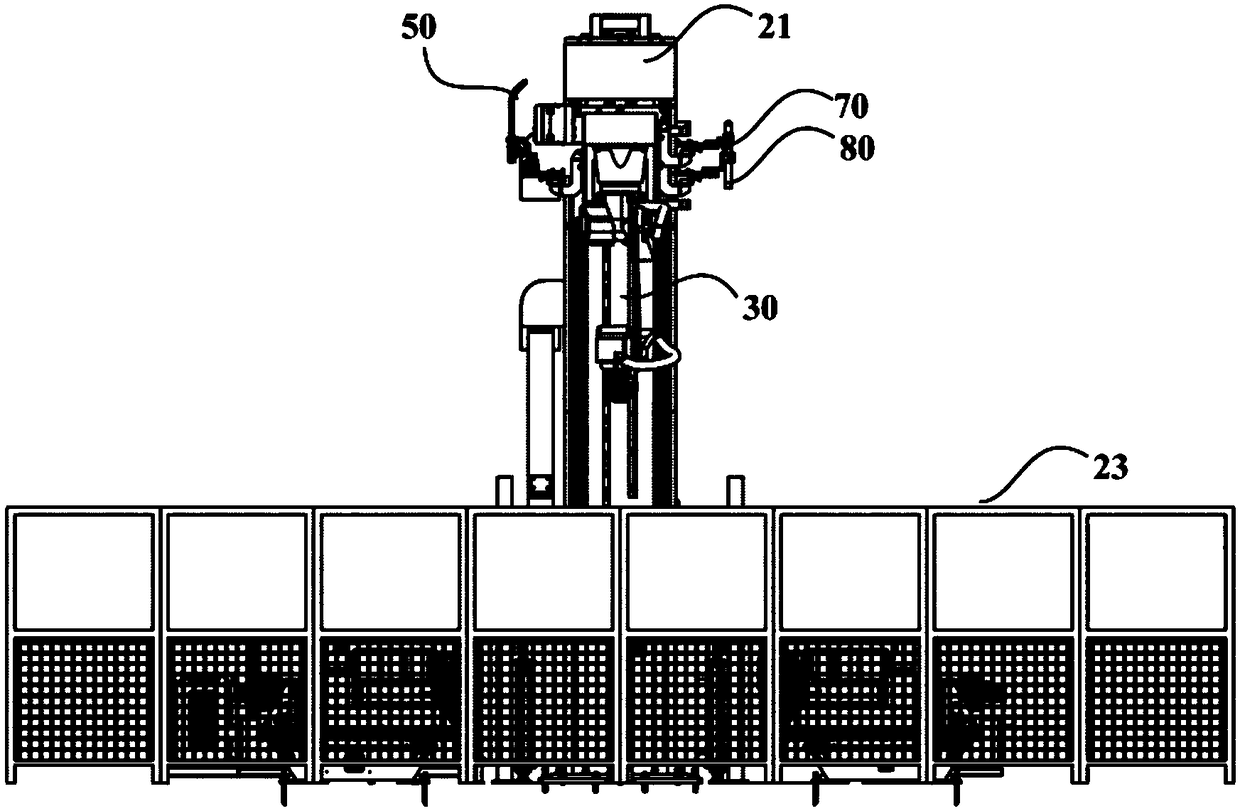

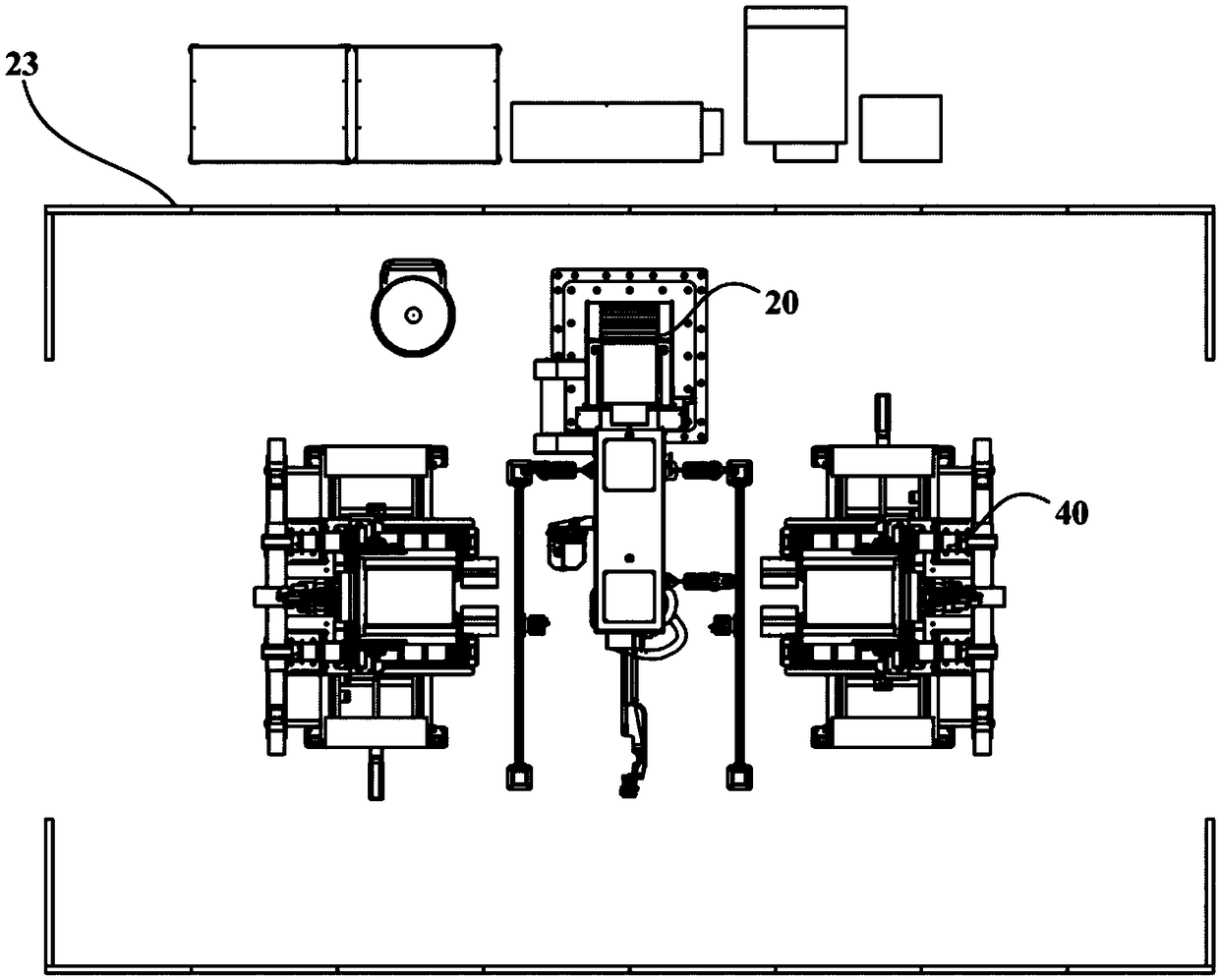

[0047] figure 1 It is a structural diagram of a robot automatic gouging welding steel ring workstation according to an embodiment of the present invention. Such as figure 1 shown and refer to Figure 2 to Figure 8, the embodiment of the present invention provides a robot automatic gouging welding steel ring workstation. The robot automatic gouging welding steel ring workstation includes a machine base 20, a robot 30, a roller frame 40, a point laser 50, a welding torch 60, a camera 70, and a gouging gun 80. Specifically, the stand 20 has a lifting device. The robot 30 is installed on the lifting device, so as to move up and down with the lifting device. The roller frame 40 is arranged on one side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com