Efficient and safe die cutting mechanism

An efficient and safe technology, applied in container manufacturing machinery, paper/cardboard containers, box making operations, etc., can solve problems such as affecting workers' life safety, adversely processing cardboard, reducing processing efficiency, etc., to reduce manual operations, processing efficiency and The effect of improving economic efficiency and efficient and fast paper feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

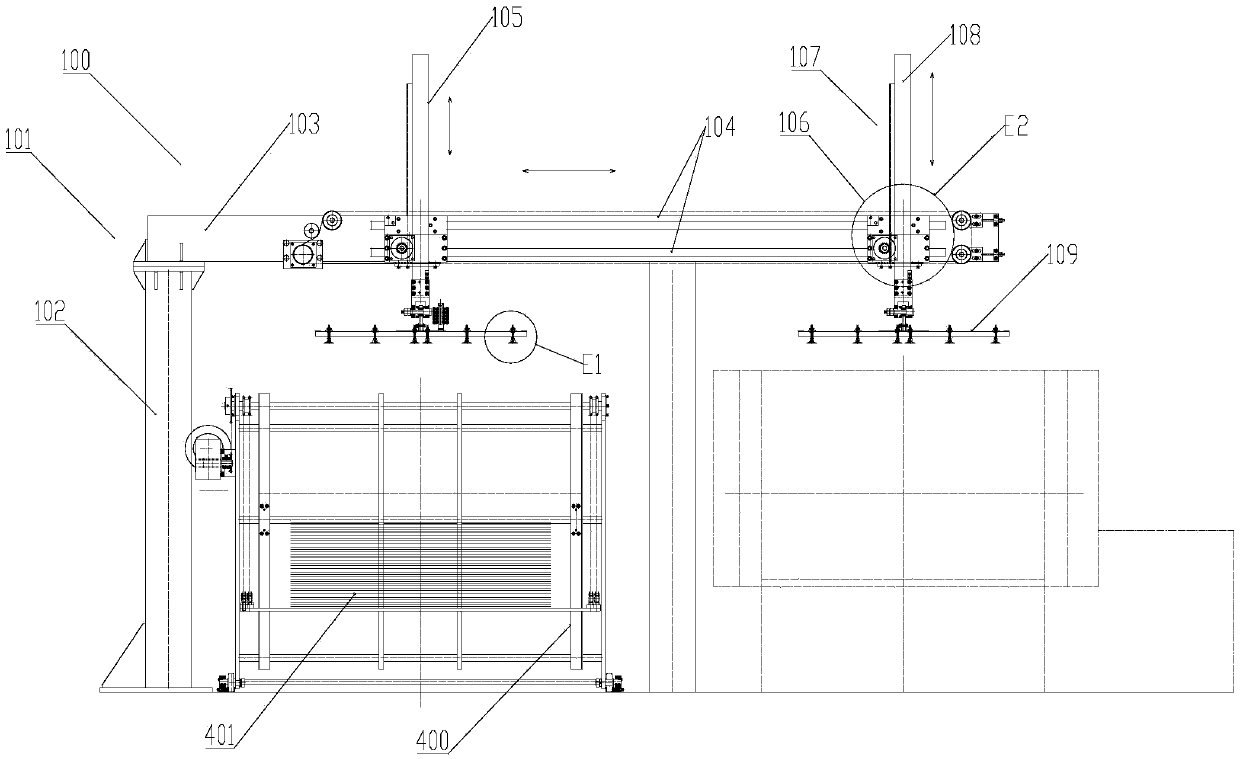

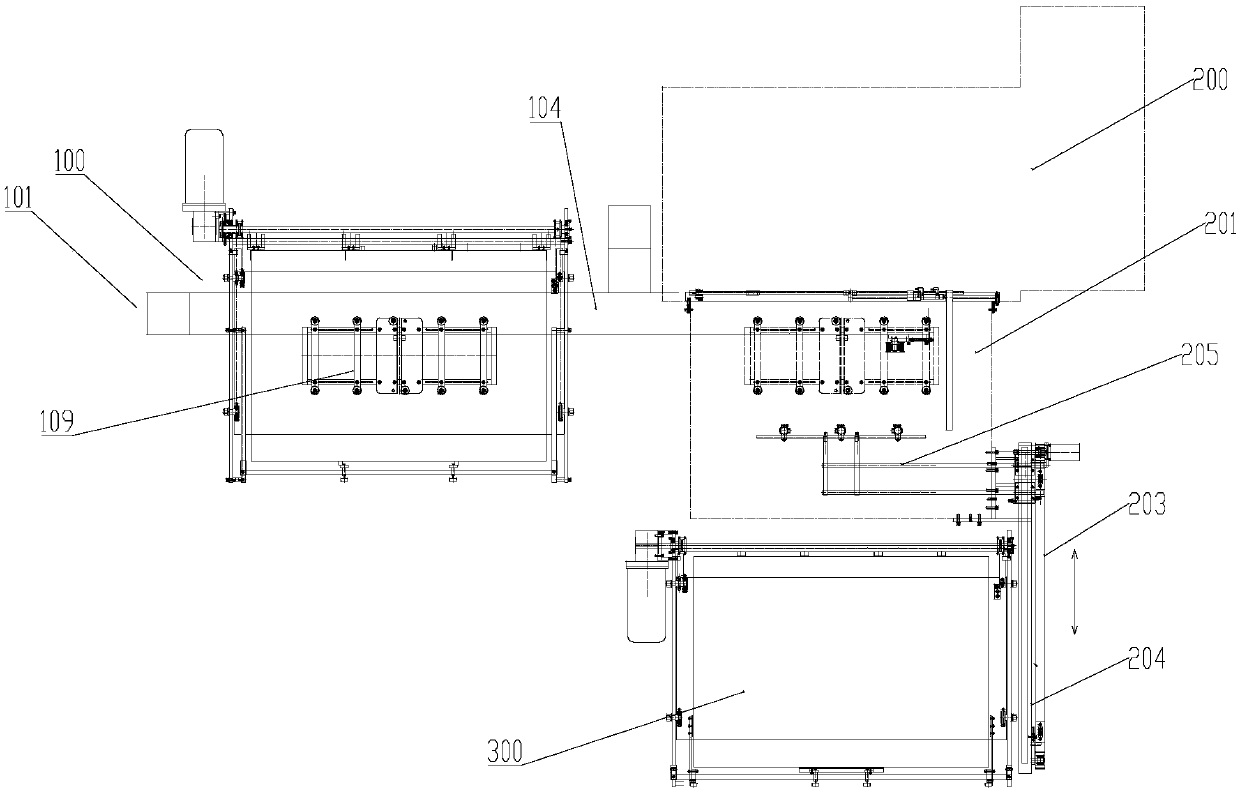

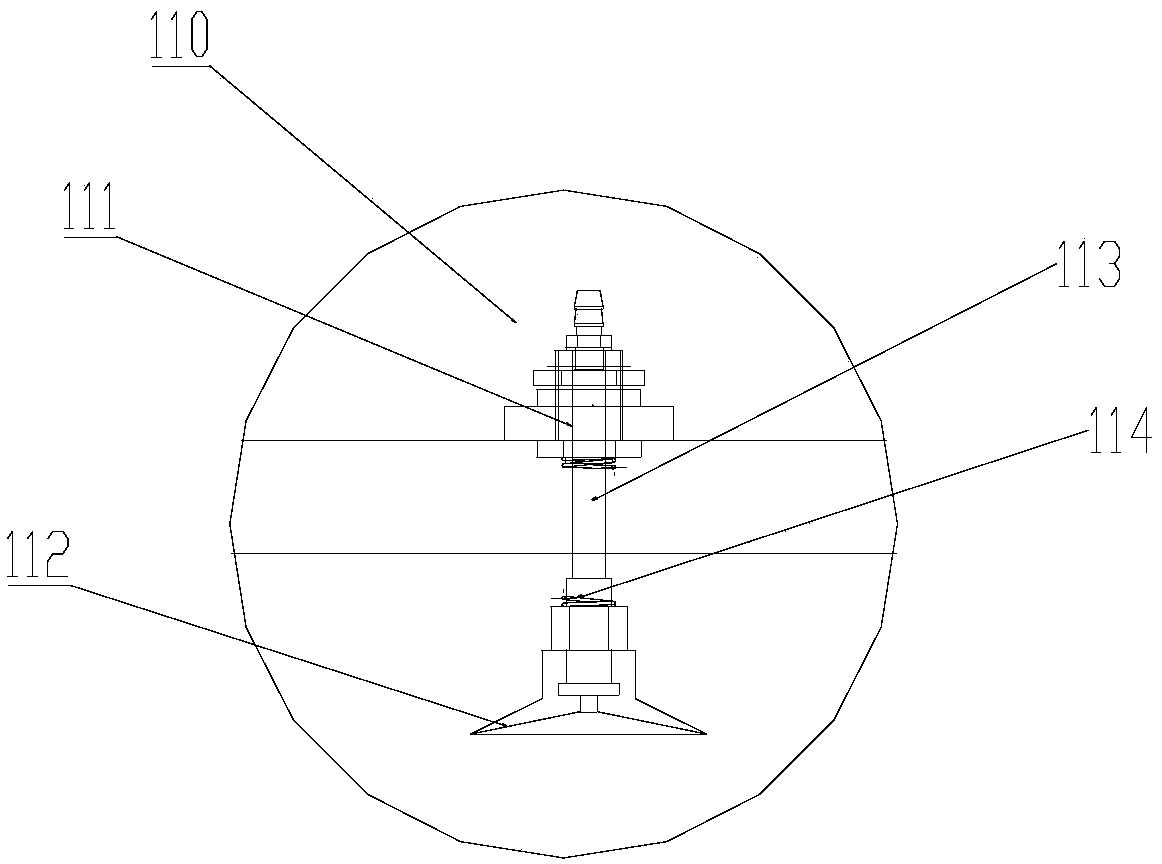

[0042] Such as figure 1 , 2 An efficient and safe die-cutting mechanism is shown. The die-cutting mechanism includes a fast paper feeding device 100 and a high-efficiency die-cutting device 200. The fast paper feeding device 100 includes a main body holder 101, which consists of two The longitudinal strut 102 on the side and the transverse guide rod 103 supported by the longitudinal strut 102 are formed. One end of the transverse guide rod 103 is connected to the upper end of the longitudinal strut 102 on one side, and the other end faces the longitudinal strut 102 on the other side. A first guide rail 104 is provided on the lateral guide rod 103, and a first mechanical arm 105 is provided on the first guide rail 104. When the fast paper feeding device is in use, the first mechanical arm 105 can replace the way of picking up the cardboard 401 in the traditional manual cardboard grasping bracket 400 to grasp and transport the cardboard 401 very quickly and stably. The set first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com