Numerical control engraving and milling method of stone plate vessel

A technology of milling processing and utensils, which is applied in the field of CNC engraving and milling processing of stone plates and utensils, which can solve the problems of large thickness and incapable of mass production, and achieve the effect of high processing quality, strong practicability, and meeting processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

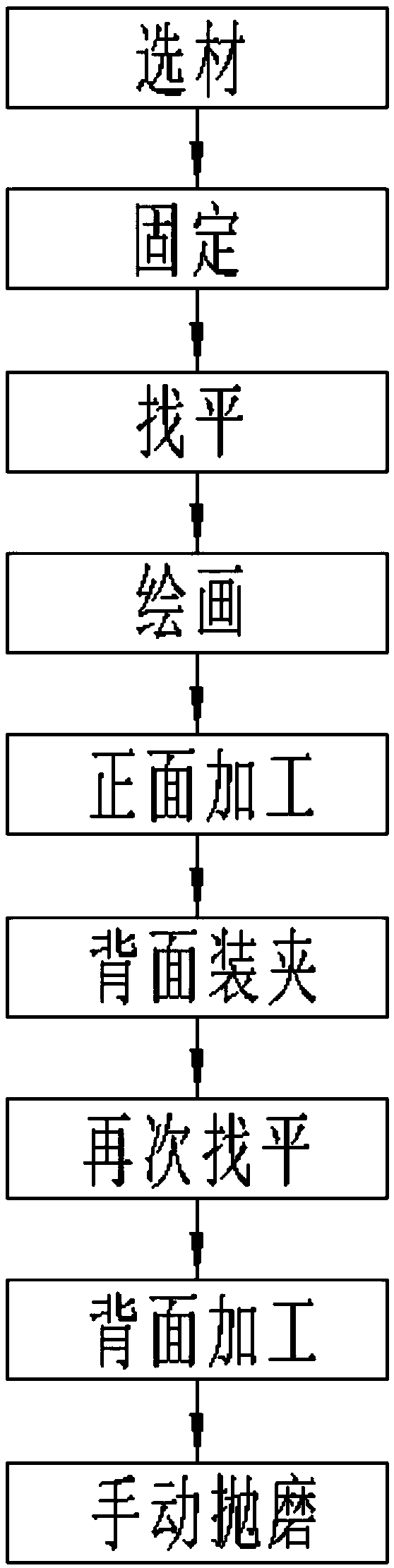

[0030] see figure 1 , in an embodiment of the present invention, a numerical control engraving and milling processing method for a stone plate vessel, comprising the following steps:

[0031] (1) Material selection: According to the thickness of the plate utensils required, choose a stone without cracks and crystal lines. The shape and size of the material are larger than the specifications of the plate utensils. Amplification can avoid the error of leveling and ensure the shape and specification of the plate and utensil;

[0032] (2) Fixing: Fix the stone material on the engraving machine tool, and clamp it on all sides until it does not loosen;

[0033] (3) Leveling: The engraving tool takes the center surface of the material as the origin, and leveling in the center;

[0034] (4) Drawing: use computer CAD / CAM software to design and draw the three-dimensional geometric surface model of the plate and vessel;

[0035] (5) Front side processing: On the basis of the three-dim...

Embodiment 2

[0041] In another embodiment of the present invention, a CNC engraving and milling processing method for a stone plate vessel includes the following steps: when the edge of the processed plate vessel is undulating like a lotus leaf edge, step (5) and step (8 ) reverse the processing sequence, that is, the back side is processed first on the enlarged blank. It can be clamped and fixed smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com