Imitated marble wall structure

A technology of imitating marble and filling layer, applied in the direction of wall, building components, building structure, etc., can solve the problems of inconsistent color, heavy natural stone, complicated construction process, etc., to achieve rich texture, low self-weight, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

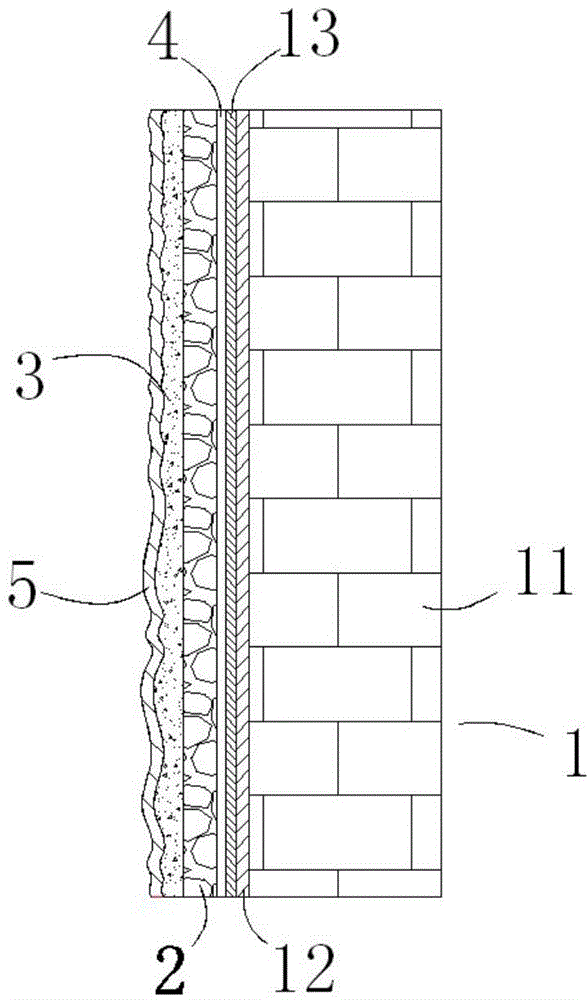

[0016] Example: see figure 1 , a kind of imitation marble wall structure that the present embodiment provides, it comprises a wall main body 1, and it also comprises an aggregate filling layer 2 and one is coated on this aggregate filling layer 2, and the upper surface is rough surface imitation Marble coating 3, the aggregate filling layer 2 is attached to the wall body 1.

[0017] The thickness of the aggregate filling layer 2 is 1-3 mm.

[0018] The thickness of the marble-like coating 3 is 50-100 microns.

[0019] The wall body 1 includes a wall base 11 and a coarse putty layer 12 and a fine putty layer 13 coated on the wall base 11 in sequence.

[0020] It also includes a primer layer 4 which is arranged between the delicate sub-layer 13 and the aggregate filling layer 2 .

[0021] It also includes a finishing oil layer 5 coated on the imitation marble coating 3 .

[0022] The components and weight percentages of imitation marble coating 3 are as follows: 20% of silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com