Manufacturing method of perrhenic acid aqueous solution from rhenium sulfide

A manufacturing method and technology for aqueous solutions, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Hereinafter, examples of the present invention will be described, but the examples are for the purpose of illustration and are not intended to limit the invention.

[0089] (Verification of the effect by the first roasting)

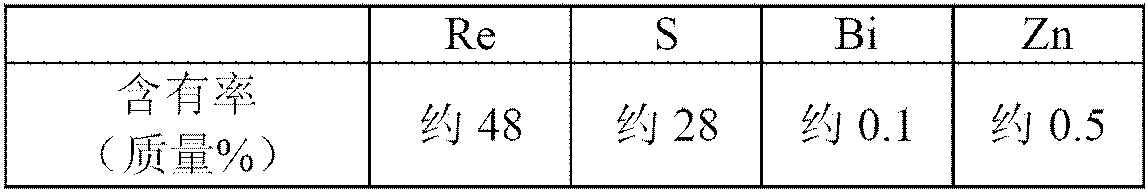

[0090] Crude rhenium sulfide having the analytical values described in Table 1 was prepared. The content rate of each component was measured by chemical analysis (analyzed by ICP-OES.).

[0091] 【Table 1】

[0092]

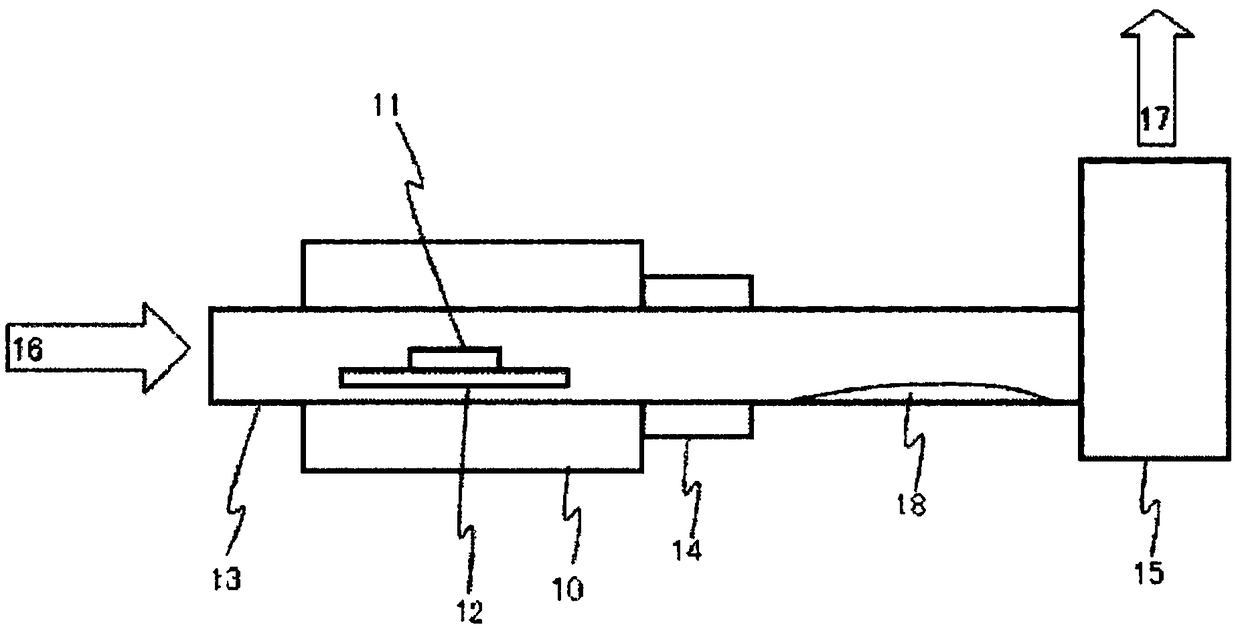

[0093] For 500 g of the crude rhenium sulfide, the first firing was carried out for 120 to 140 minutes under various furnace atmosphere temperature conditions, and then the furnace was cooled to room temperature. A kiln is used as the roasting furnace, and air is used as the oxygen-containing gas. In any case, the oxygen equivalent was in the range of 1.9 to 2.2. In addition, it can be seen that when the air is preheated to a predetermined temperature (here, 140° C.) and supplied to the kiln, the temperature of the atmosphere i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com