High-density and high-proportion polyester blended fabric without PVA (polyvinyl alcohol) sizing slurry and sizing method

A blended fabric, high proportion technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problem that pure polyester fabric cannot achieve PVA-free sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

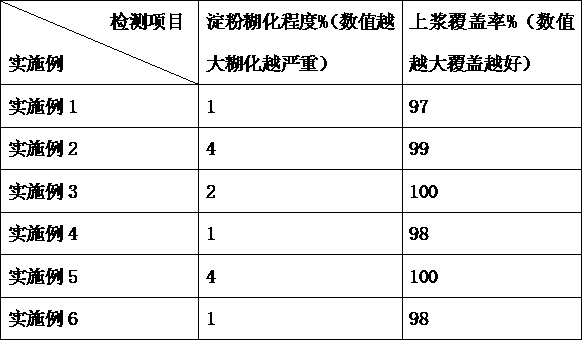

Examples

example 1

[0040] High-density and high-proportion polyester blended fabric without PVA sizing, which is composed of the following raw materials in parts by weight: 45 parts of 309 green environmental protection slurry, 62.5 parts of corn starch, and 1 part of smoothing agent;

[0041] The 309 green slurry is composed of the following raw materials in parts by weight: 80 parts of starch, 12 parts of acrylic acid, 6 parts of acrylamide, 0.5 part of itaconic acid, 1.5 parts of sodium hydroxide and 0.3 part of dibenzoyl peroxide.

[0042] The sizing method of the above-mentioned high-density and high-ratio polyester blended fabric without PVA sizing material comprises the following steps:

[0043] a Raw material preparation: Weigh 309 green environmental protection slurry, corn starch, and smoothing agent according to weight for use;

[0044] b pulping process:

[0045] Using the fixed volume mixing operation mode,

[0046] High pressure barrel mixing

[0047] (1) Temperature setting: Us...

example 2

[0069] High-density and high-proportion polyester blended fabric without PVA sizing, which is composed of the following raw materials in parts by weight: 45 parts of 309 green environmental protection slurry, 62.5 parts of corn starch, and 1 part of smoothing agent;

[0070]The 309 green slurry is composed of the following raw materials in parts by weight: 80 parts of starch, 12 parts of acrylic acid, 6 parts of acrylamide, 0.5 part of itaconic acid, 1.5 parts of sodium hydroxide and 0.3 part of dibenzoyl peroxide.

[0071] The sizing method of the above-mentioned high-density and high-ratio polyester blended fabric without PVA sizing material comprises the following steps:

[0072] a Raw material preparation: Weigh 309 green environmental protection slurry, corn starch, and smoothing agent according to weight for use;

[0073] b pulping process:

[0074] Using the fixed volume mixing operation mode,

[0075] High pressure barrel mixing

[0076] (1) Temperature setting: use...

example 3

[0098] High-density and high-proportion polyester blended fabric without PVA sizing, which is composed of the following raw materials in parts by weight: 45 parts of 309 green environmental protection slurry, 62.5 parts of corn starch, and 1 part of smoothing agent;

[0099] The 309 green slurry is composed of the following raw materials in parts by weight: 80 parts of starch, 12 parts of acrylic acid, 6 parts of acrylamide, 0.5 part of itaconic acid, 1.5 parts of sodium hydroxide and 0.3 part of dibenzoyl peroxide.

[0100] The sizing method of the above-mentioned high-density and high-ratio polyester blended fabric without PVA sizing material comprises the following steps:

[0101] a Raw material preparation: Weigh 309 green environmental protection slurry, corn starch, and smoothing agent according to weight for use;

[0102] b pulping process:

[0103] Using the fixed volume mixing operation mode,

[0104] High pressure barrel mixing

[0105] (1) Temperature setting: Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com