A vibration and noise reduction structure of a highway tunnel and a construction method thereof

A vibration reduction and noise reduction technology for road tunnels, applied in tunnels, tunnel linings, tracks, etc., can solve problems such as poor vibration reduction effects, noise pollution, and reduce vertical stiffness of tunnel structures, so as to reduce noise and prevent ballast bed settlement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

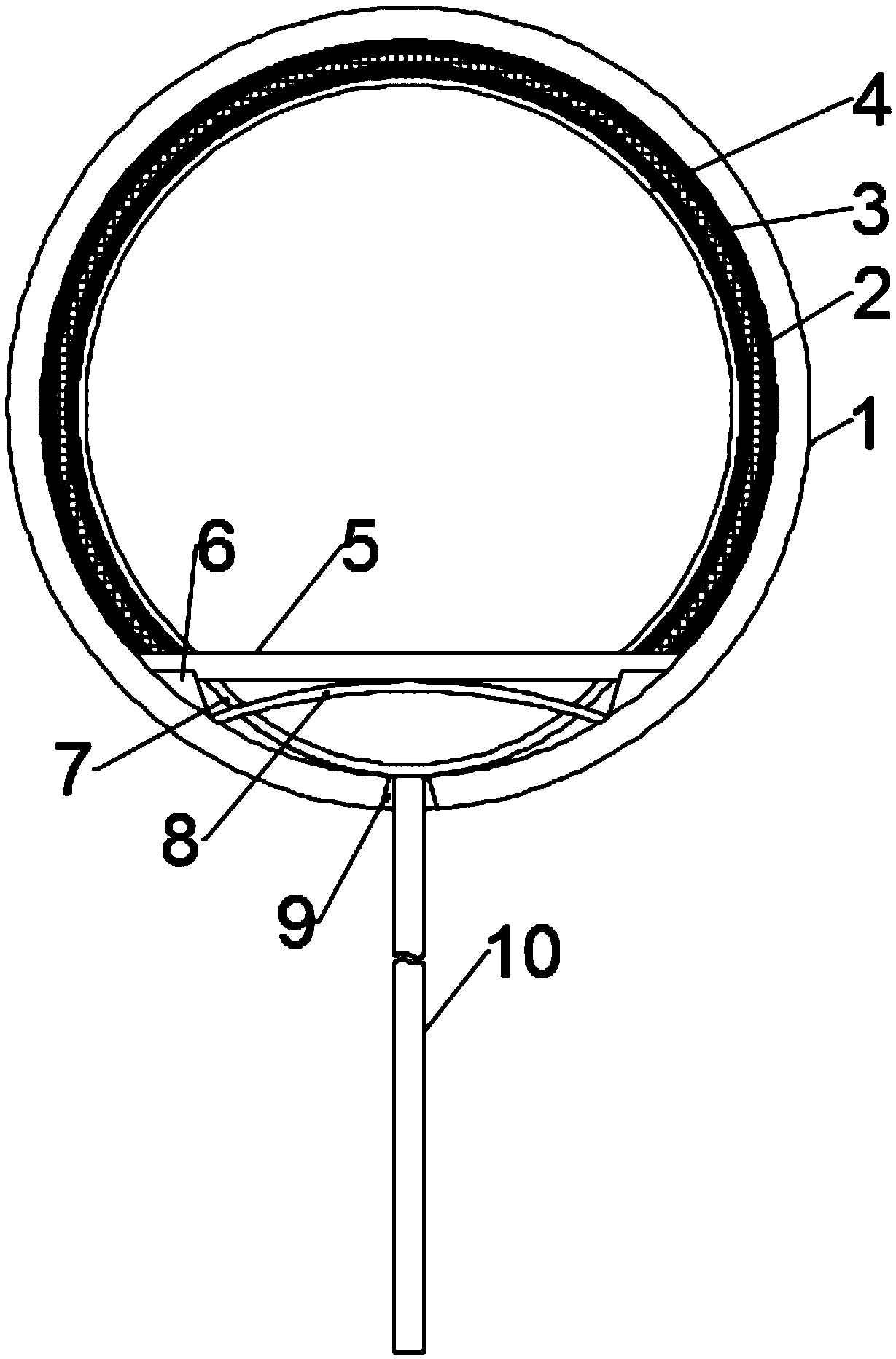

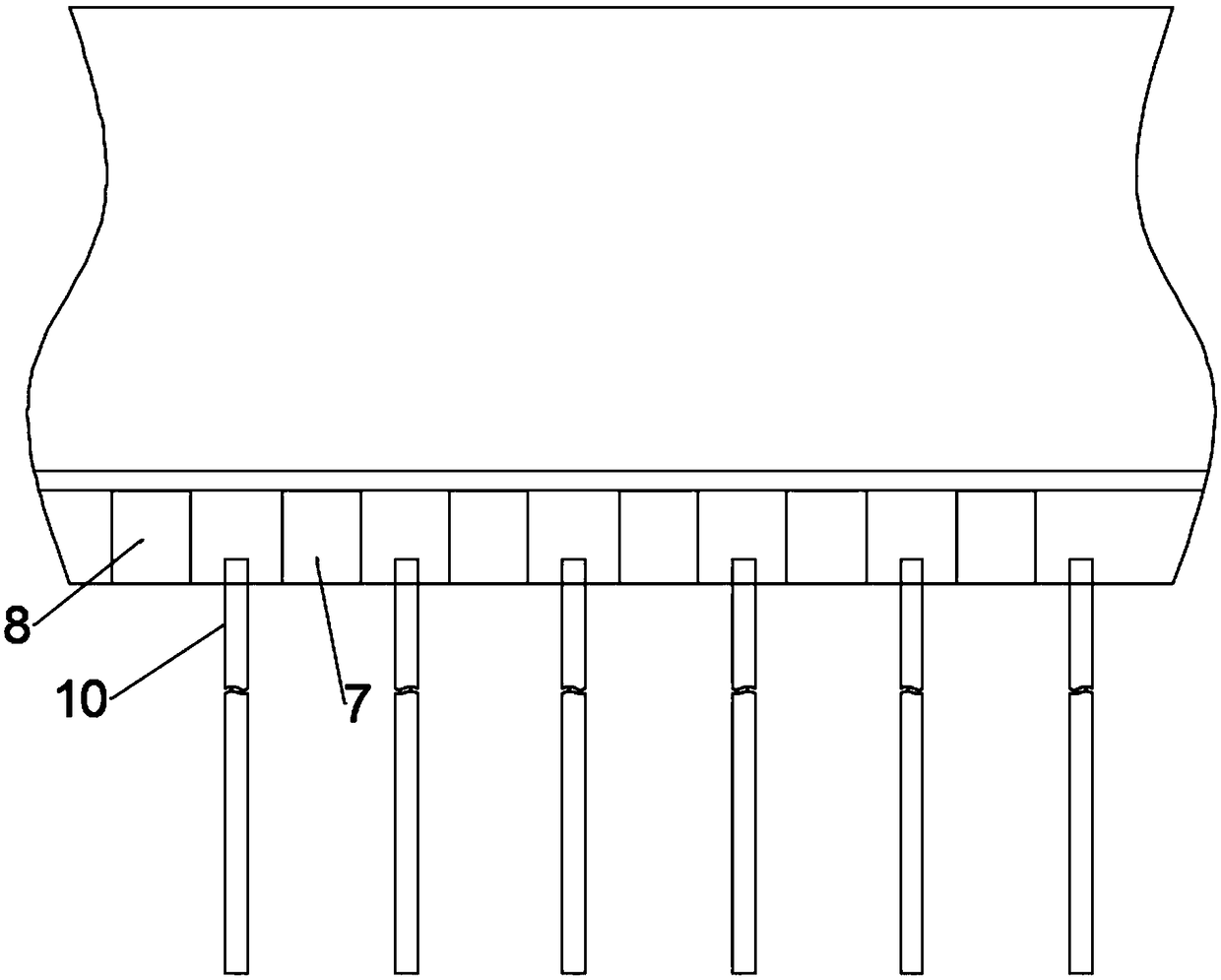

[0024] A road tunnel vibration and noise reduction structure, comprising a tunnel segment 1 and a ballast bed 5, both sides of the bottom of the ballast bed 5 are poured with supporting foundations 6, and the ballast bed 5 and the tunnel segment 1 are provided with a third One curved steel bar 8 and the second curved steel bar 7, the first curved steel bar 8 is opposite to the second curved steel bar 7, and the first curved steel bar 8 and the second curved steel bar 7 can The ballast bed 5 is supported to prevent the ballast bed 5 from settling. At the same time, because the first arc-shaped steel bar 8 and the second arc-shaped steel bar 7 have certain deformation properties, they have a certain vibration-reducing effect. The bottom of the tunnel segment 1 is located at A steel pipe pile 10 is pierced between the adjacent first arc-shaped steel bar 8 and the second arc-shaped steel bar 7, and a through hole 9 for the steel pipe pile 10 to pass through is opened on the tunnel ...

Embodiment 2

[0033] A road tunnel vibration and noise reduction structure, comprising a tunnel segment 1 and a ballast bed 5, both sides of the bottom of the ballast bed 5 are poured with supporting foundations 6, and the ballast bed 5 and the tunnel segment 1 are provided with a third One curved steel bar 8 and the second curved steel bar 7, the first curved steel bar 8 is opposite to the second curved steel bar 7, and the first curved steel bar 8 and the second curved steel bar 7 can The ballast bed 5 is supported to prevent the ballast bed 5 from settling. At the same time, because the first arc-shaped steel bar 8 and the second arc-shaped steel bar 7 have certain deformation properties, they have a certain vibration-reducing effect. The bottom of the tunnel segment 1 is located at A steel pipe pile 10 is pierced between the adjacent first arc-shaped steel bar 8 and the second arc-shaped steel bar 7. The tunnel segment 1 is provided with a through hole 9 for the steel pipe pile 10 to pas...

Embodiment 3

[0041] A road tunnel vibration and noise reduction structure, comprising a tunnel segment 1 and a ballast bed 5, both sides of the bottom of the ballast bed 5 are poured with supporting foundations 6, and the ballast bed 5 and the tunnel segment 1 are provided with a third One curved steel bar 8 and the second curved steel bar 7, the first curved steel bar 8 is opposite to the second curved steel bar 7, and the first curved steel bar 8 and the second curved steel bar 7 can The ballast bed 5 is supported to prevent the ballast bed 5 from settling. At the same time, because the first arc-shaped steel bar 8 and the second arc-shaped steel bar 7 have certain deformation properties, they have a certain vibration-reducing effect. The bottom of the tunnel segment 1 is located at A steel pipe pile 10 is pierced between the adjacent first arc-shaped steel bar 8 and the second arc-shaped steel bar 7. The tunnel segment 1 is provided with a through hole 9 for the steel pipe pile 10 to pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com