Slurry overflow preventing variable cross-section cement-soil mixing pile head

A technology of cement-soil mixing pile and variable section, which is applied to sheet pile walls, soil protection, construction, etc., can solve the problems of large settlement deformation, smaller diameter of the pile body, and single shape of the pile body, so as to improve the quality of the pile. , The effect of reducing delamination and saving drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

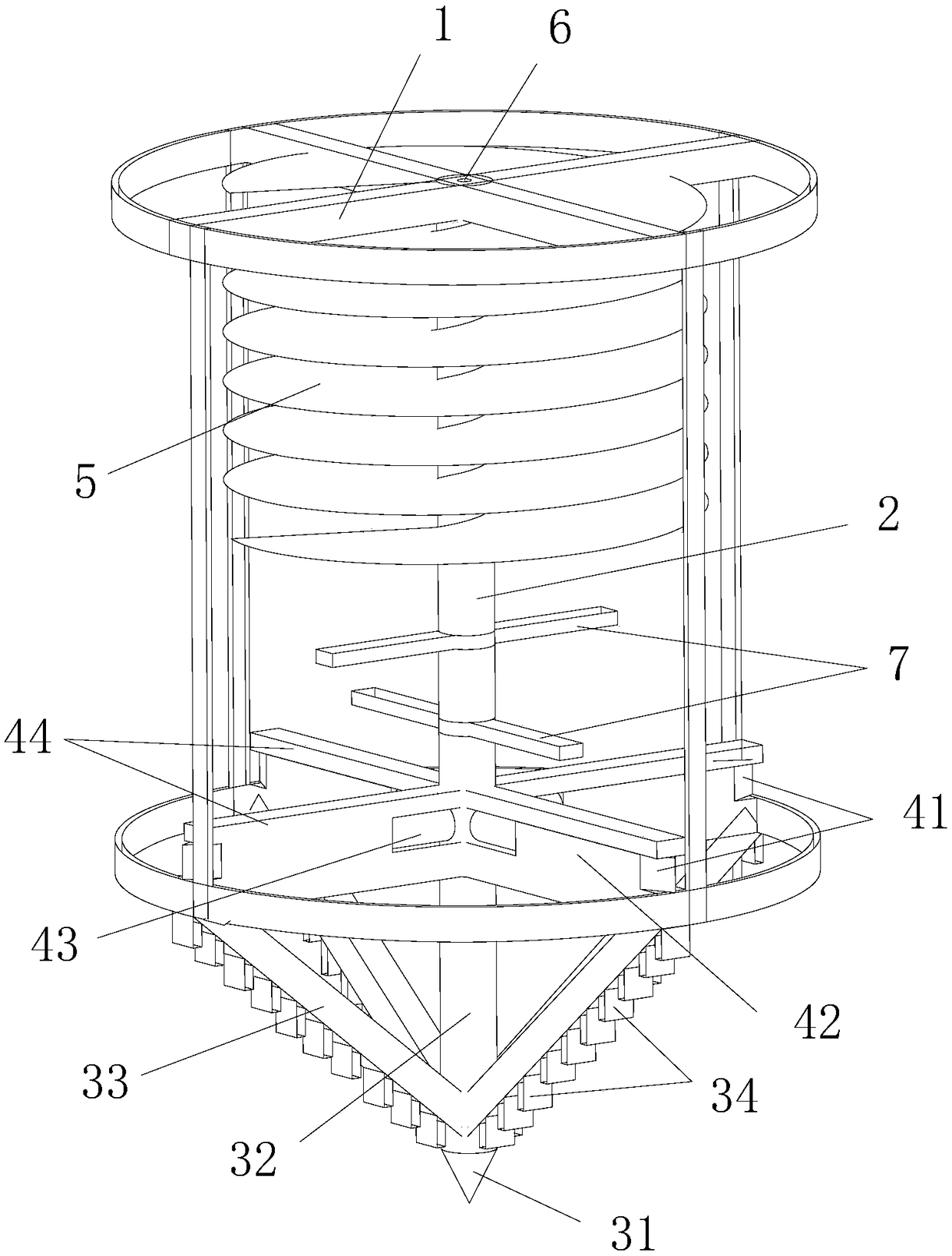

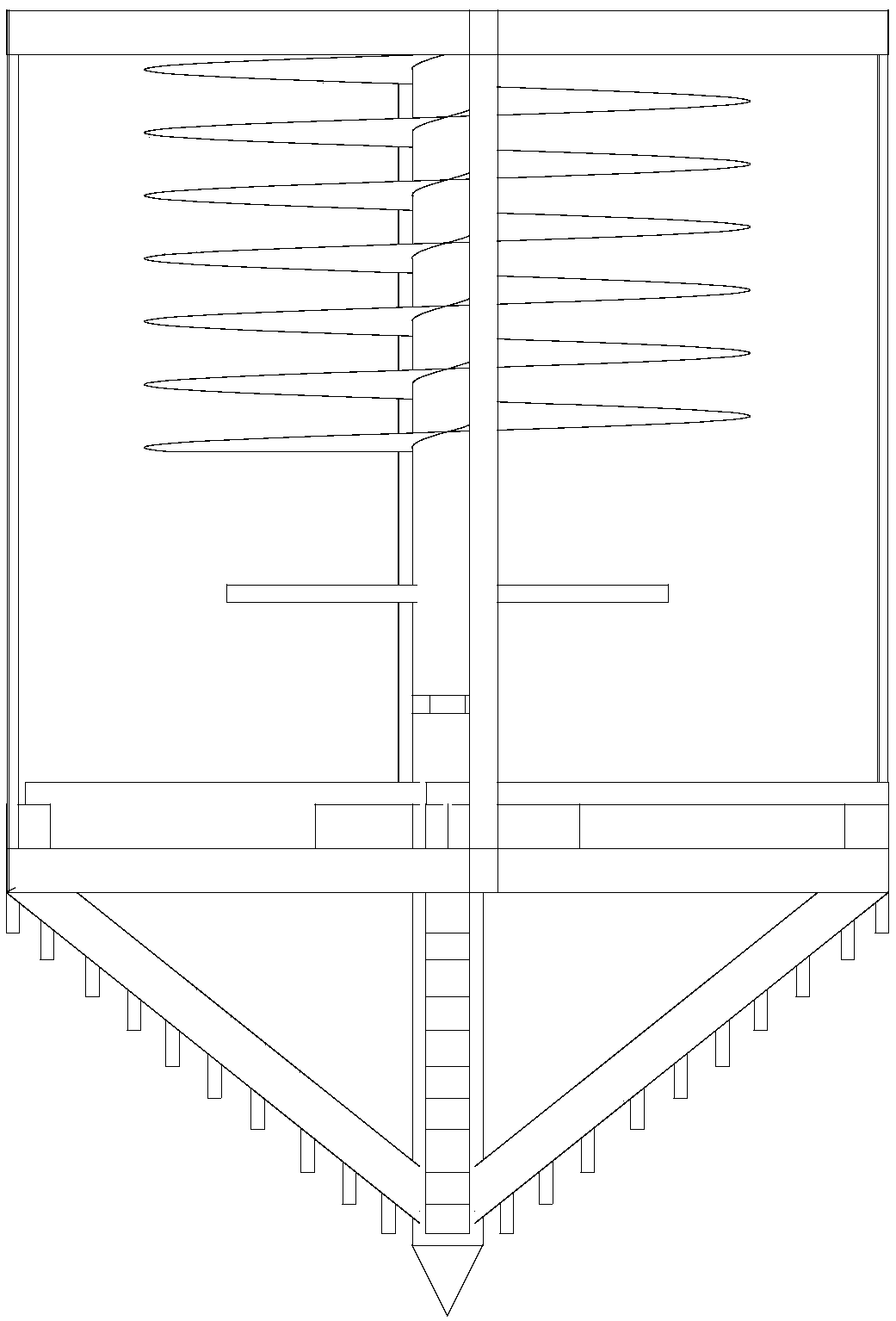

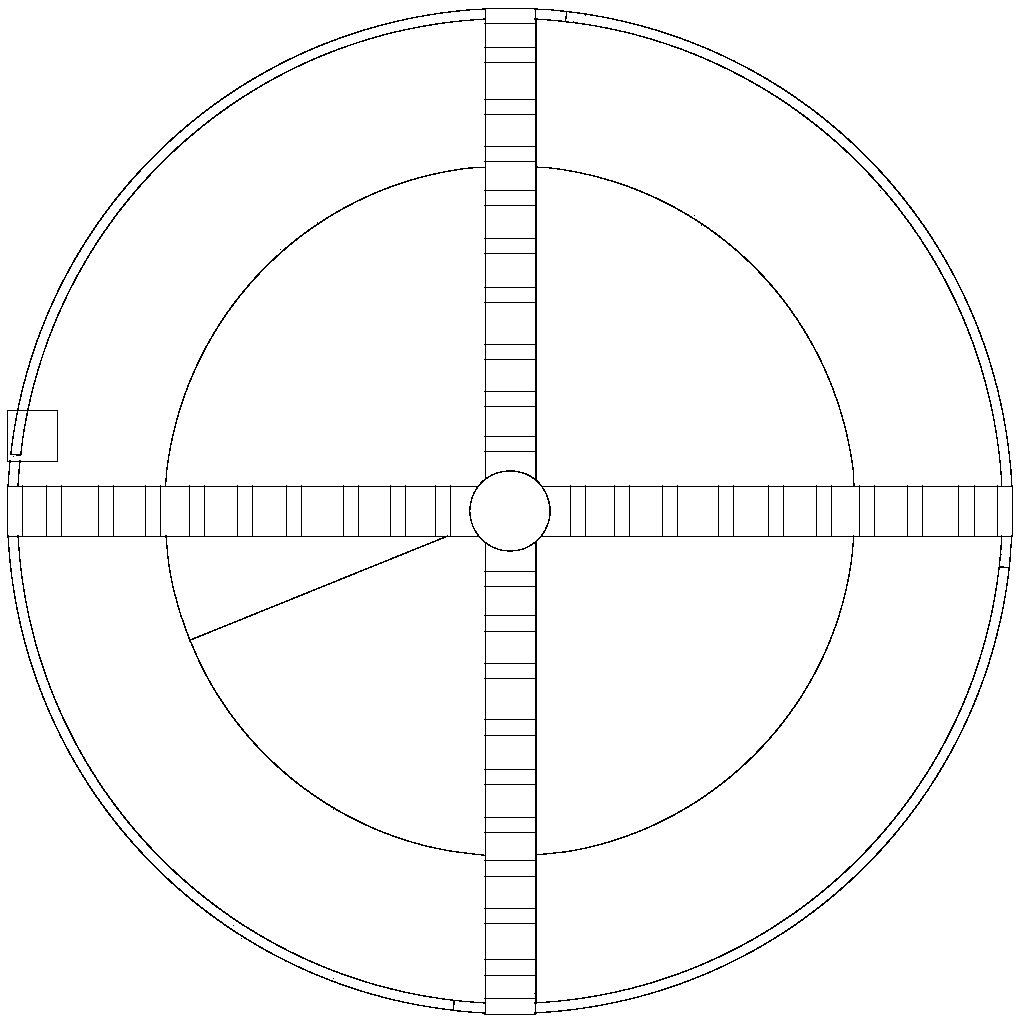

[0030] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a cement-soil mixing pile head with a variable cross-section for anti-overflow, which mainly includes a pile head body 1, a rotating rod 2 arranged in the pile head body 1, and a cone for drilling A drill bit, an edge expansion part for enlarging the diameter of the pile, a stirring blade 5 for preventing slurry overflow, and a slurry inlet channel 6 for transporting cement slurry. The top of the pile head body 1 is connected to the power shaft of the construction equipment through transmission, and the pile head body 1 is driven to rotate. The conical drill bit is arranged at the bottom of the pile head body 1 and is fixedly connected with the pile head body 1 . The edge expansion part is arranged at the bottom of the pile head body 1, above the conical drill bit, and can extend outward or shrink inward. When extending outward and cutting the soil, the diameter of the pile can be enlarged. The stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com