Fireproof decorative board combined with straw and preparation process and installation method thereof

A decorative board and straw technology, applied in the field of building decoration, can solve the problems of surface board deformation, influence on appearance, insufficient internal strength, etc., and achieve the effects of reducing strength, reliable overall strength, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

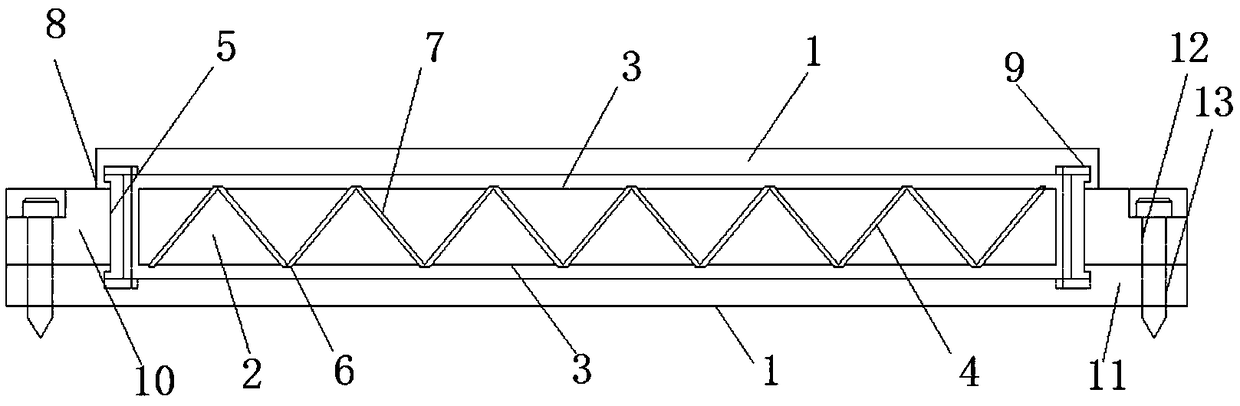

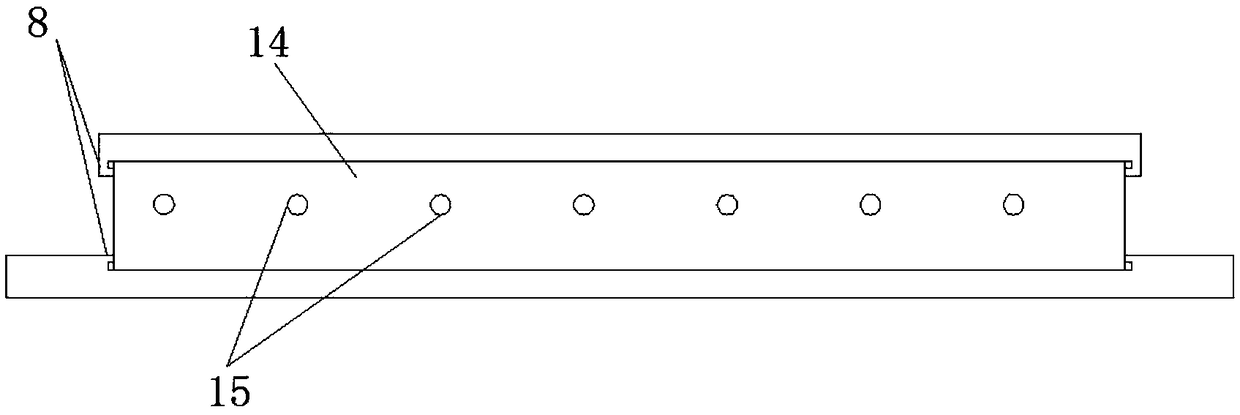

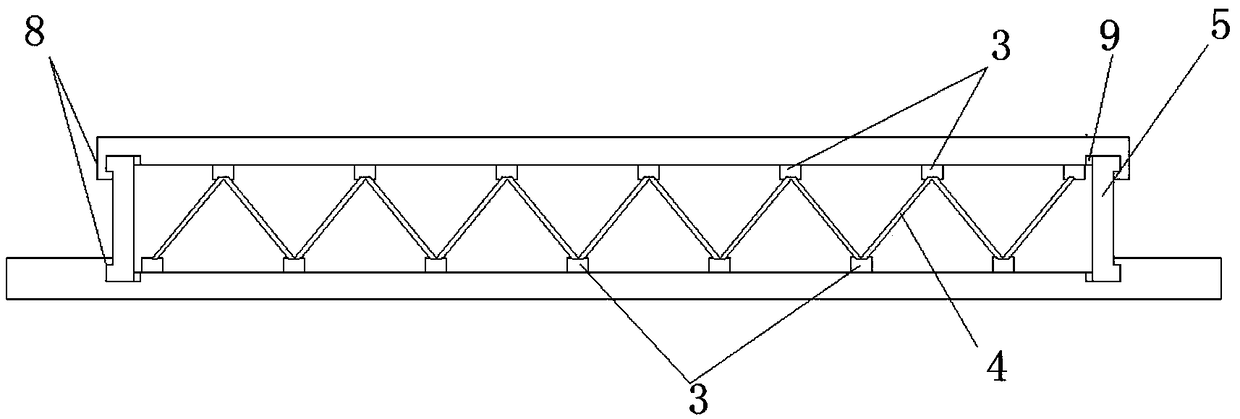

[0043] Such as Figure 1-Figure 4 As shown, the present invention provides a straw foamed decorative board, comprising two layers of surface panels 1 arranged on the upper and lower sides and a foam sandwich layer 2 between the surface panels 1, the foam sandwich layer 2 Evenly mixed with straw segments with a length of 2-6 mm. A reinforcing frame is also provided between the surface panels 1 , and the foam sandwich layer 2 fills the voids of the reinforcing frame. The reinforcing frame includes two layers of grid panels 3 laid on the inner sides of the two layers of surface panels 1 and a support panel connecting the grid panels 3 . The inner side of the grid plate 3 is provided with a plurality of installation grooves 16 with a trapezoidal cross section, the support plate is a corrugated plate 4 with triangular grooves, and the top of the ribs 6 of the corrugated plate 4 is ground to be consistent with the installation groove 16. The matching trapezoidal structure, the rib...

Embodiment 2

[0069] The installation method of the fireproof decorative board added with straw in this embodiment includes installing two vertical fireproof decorative boards at the corner of the wall. Adjacent fireproof decorative panels are located on two vertical walls. After pasting one of the fireproof decorative panels, a filler block 21 is inserted between the other wall and its side, and then the other fireproof decorative panel is pasted using an L-shaped connection. The fixing plate 20 covers the lower step surface of the step structure at the adjacent position of the two fireproof decorative panels, and the fixing plate 20 and the fireproof decorative panel are fixedly connected with cement nails or screws, and then the L-shaped decorative clamping plate 19 is clamped and covered on the The upper step face of the step structure.

[0070] When the decorative panel is installed, the screws or cement nails pass through the installation structure of the decorative panel on the side,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com