Device integrating leakage detection and sealing of gas extraction drill hole

A technology for gas drainage and leak detection, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problems of inability to accurately measure the pressure of high-concentration gas, affecting the smoothness of gas drainage pipelines, Difficulty in making full use of gas, etc., to achieve safe and reliable drainage process, improve gas drainage efficiency, and low input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

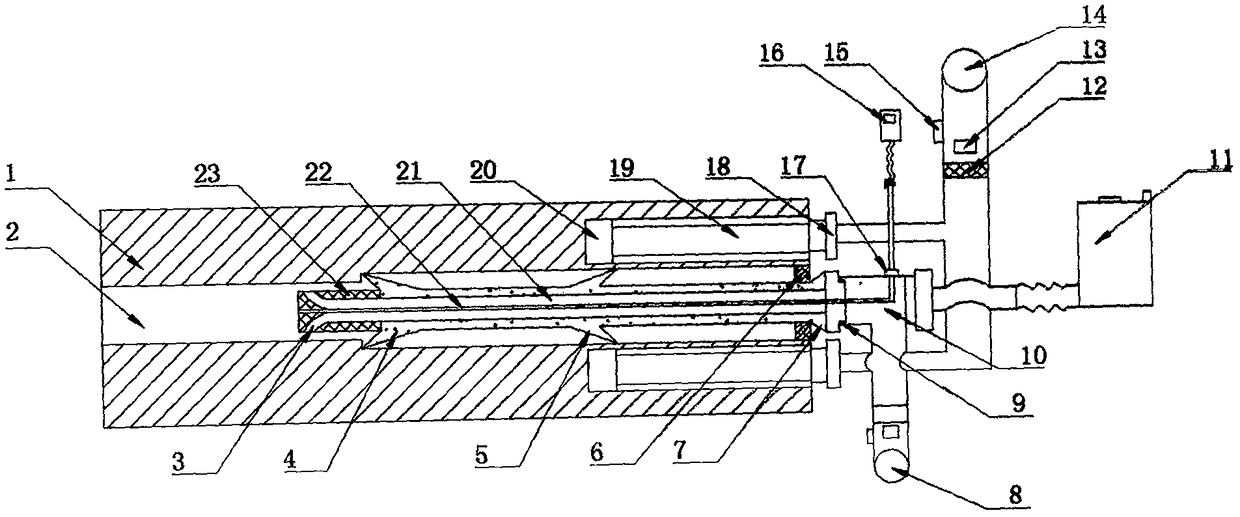

[0014] see figure 1 , an integrated device for leak detection and plugging of gas drainage boreholes, including a tee pipe 10, a filler pipe 21, a detection pipe 22, a shallow hole pumping pipe 19, a gas extraction pump 8, a gas analyzer 16 and a pressure The air injection pump 11; the stuffing pipe 21 is installed on the left port of the tee pipe 10, the compressed air injection pump 11 is communicated with the right port of the tee pipe 10 through a pipeline, and the lower port of the tee pipe 10 is connected through the extraction pipe It is communicated with the gas extraction pump 8; the packing pipe 21 extends into the borehole 2 of the coal rock mass 1, and a fixed component is set in the gap between the packing pipe 21 and the borehole 2, and the fixed component is sleeved on the outer periphery of the packing pipe 21, The inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com