Diesel vehicle DPF active regeneration temperature control method

A temperature control method and active regeneration technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of large regeneration temperature control errors, complex calculation formulas, poor control consistency, etc., and achieve fast response and calculation methods Simple, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

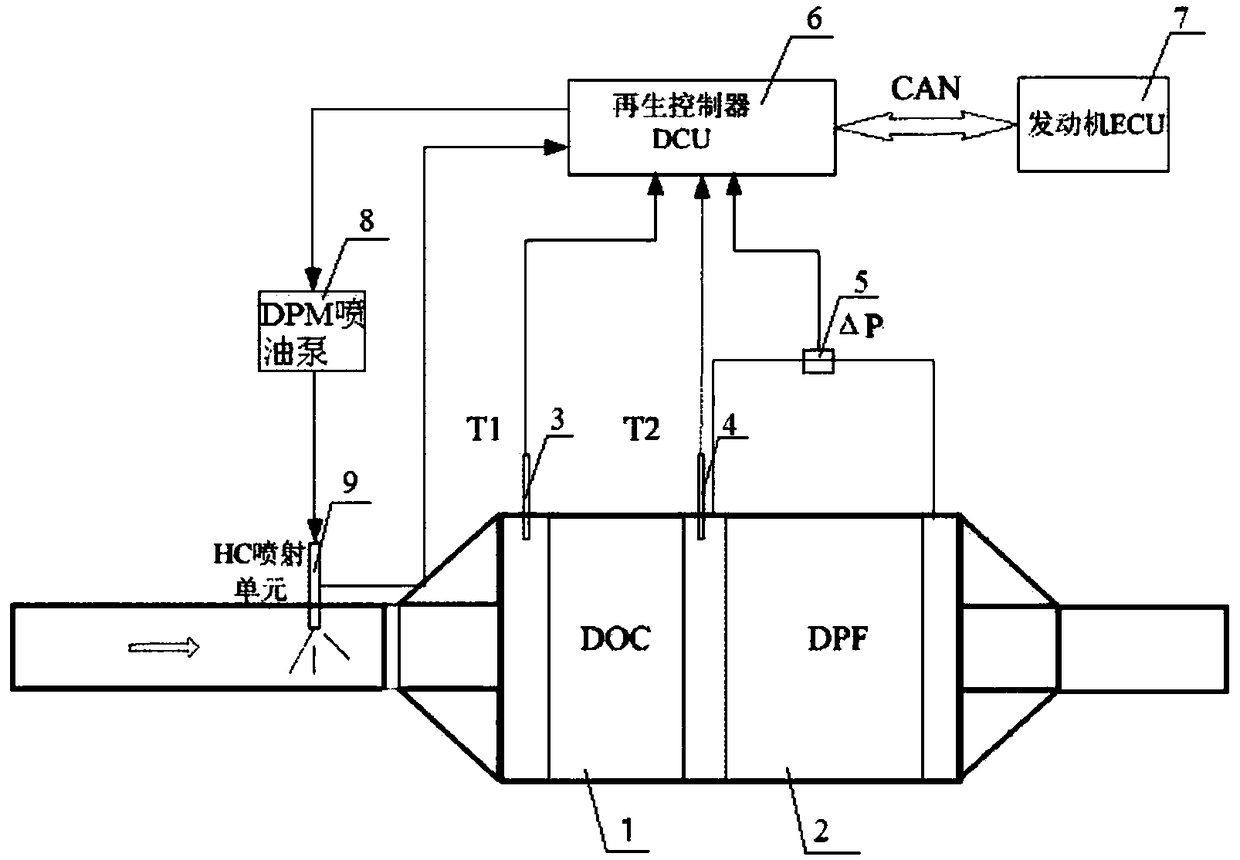

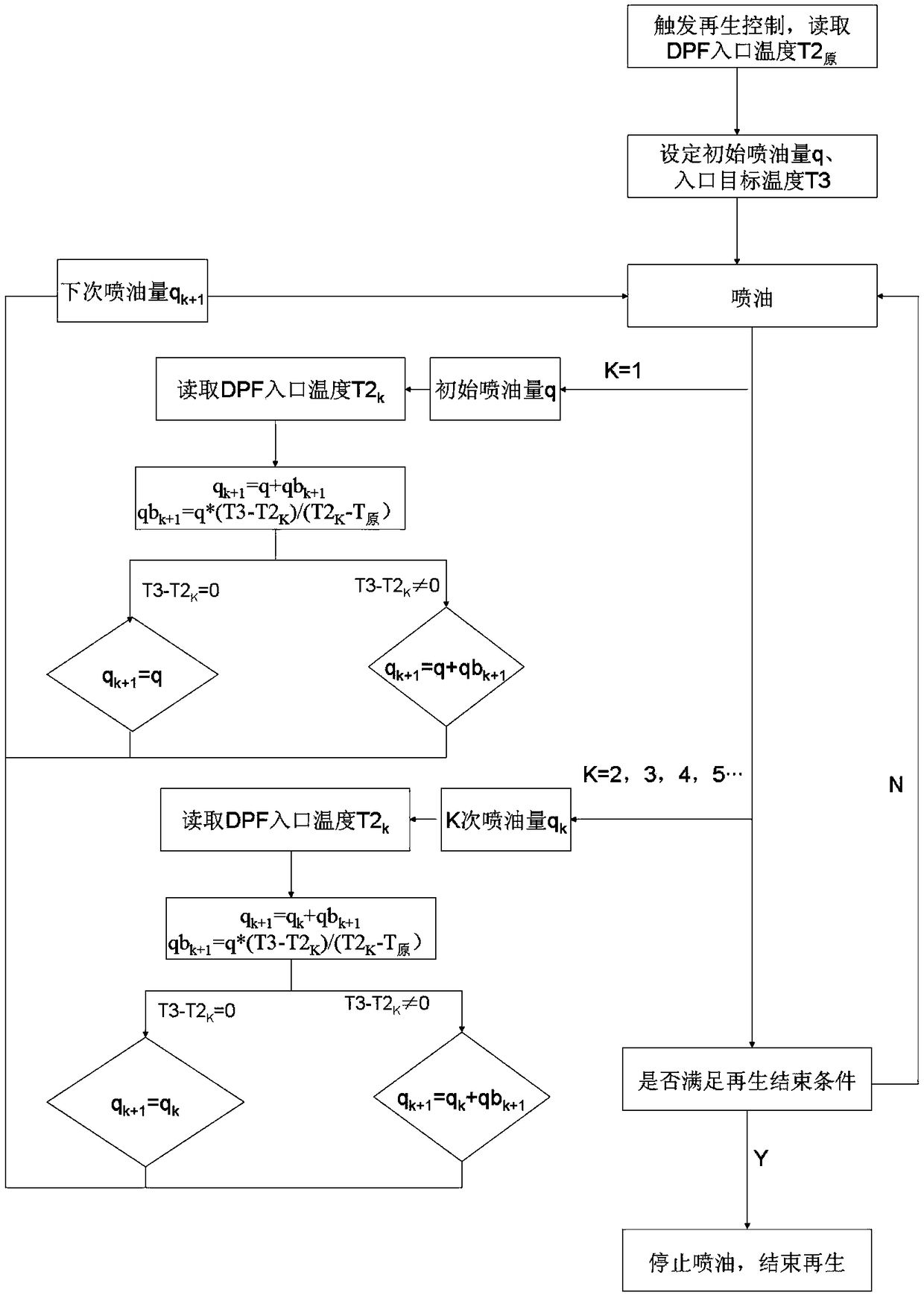

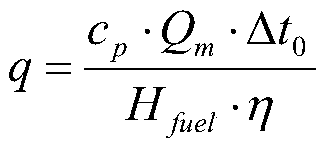

[0058] see figure 1 , figure 2 , a diesel vehicle DPF active regeneration temperature control method of the present invention, the upstream of the DPF2 is provided with a DOC1, and the upstream of the DOC1 is provided with an HC injection unit 9. Under normal circumstances, the oxidation catalyst, that is, the DOC1 and the particle trap The DPF2 will purify the exhaust gas from the diesel engine so that the particulate matter in the exhaust gas meets or meets the requirements of the national regulations. However, after a period of use, the DPF2 will pass through the HC injection unit 9 arranged upstream of the DOC1. The fuel is sprayed out to generate high temperature and active combustion of the particles trapped in the DPF2 channel for regeneration. In this field, there are many conditions for prompting the DPF2 to start active re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com