Elevated air cooling double-layer reciprocating roller kiln

A lift-type, roller kiln technology, applied in special decorative structures, decorative arts, processing of discharged materials, etc., can solve the problems of long cooling time, low production efficiency, and increased enterprise costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

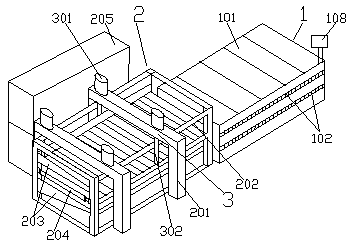

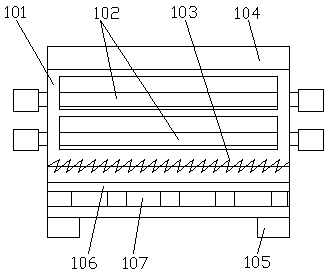

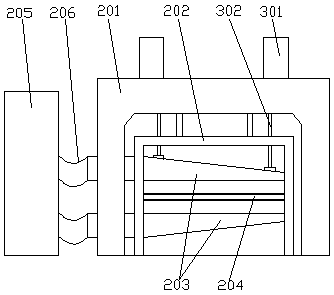

[0021] As shown in the figure, a lift-type air-cooled double-layer reciprocating roller kiln includes a double-layer reciprocating roller kiln 1 and a lift-type air grid 2. The double-layer reciprocating roller kiln 1 includes a kiln body 101, double-layer Layer rollers 102, heating furnace wire 103, thermal insulation cotton 104 and brackets 105, wherein the double-layer rollers 102 are located inside the kiln body 101, motors are arranged on both sides of the double-layer rollers 102, and the ends of the double-layer rollers 102 Connected with the output shaft of the motor, the heating furnace wire 103 is located directly under the double-layer roller bar 102; the insulation cotton 104 is located on the top of the kiln body 101, and the bracket 105 is located at the bottom of the kiln body 101, and the double-layer roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com