A high-efficiency sampling device and sampling method for rock and soil

A sampling device and high-efficiency technology, applied in the direction of sampling devices, etc., can solve the problems of insufficient sampling volume, time-consuming, easy mud bag of sandstone particles, etc., and achieve the effect of not being easy to shake, saving time consumption, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

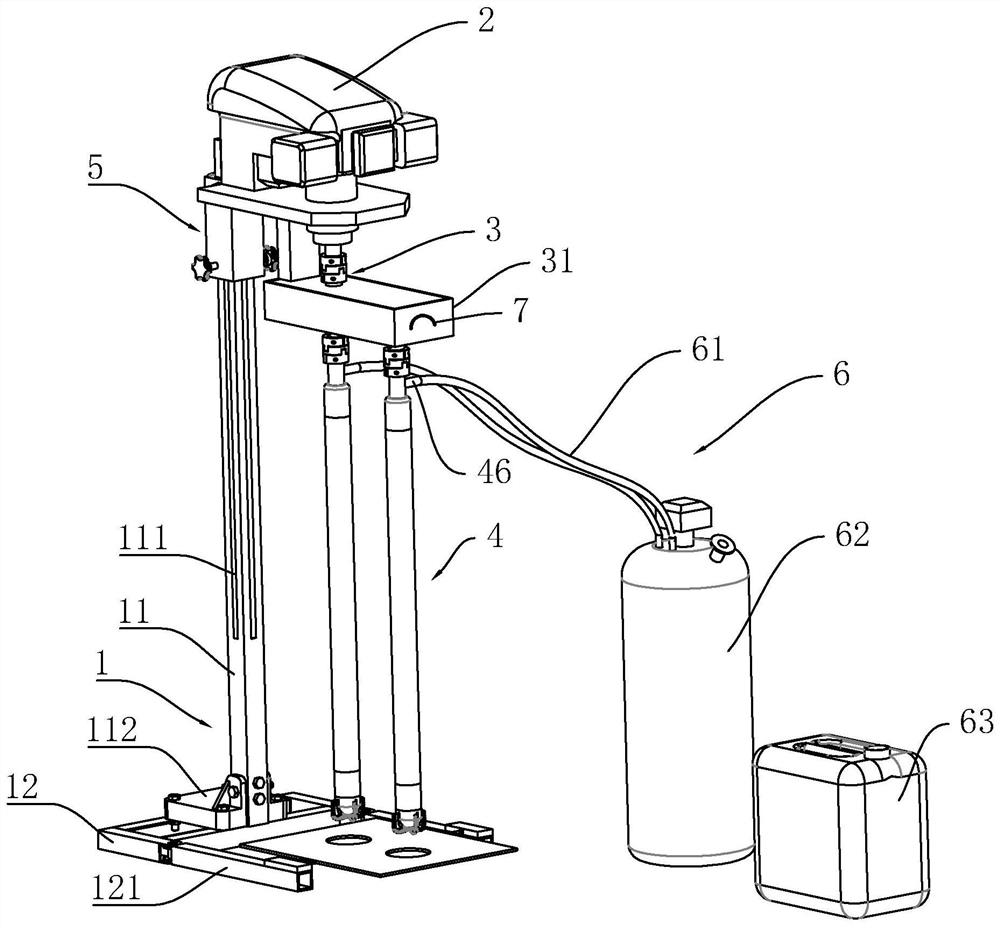

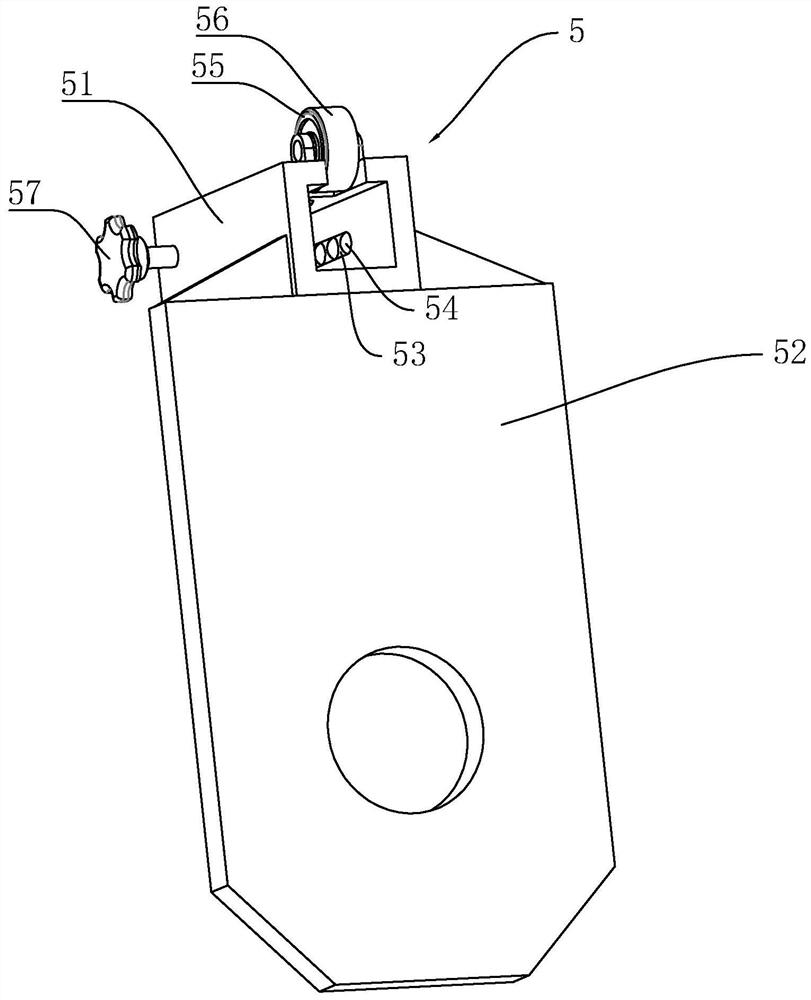

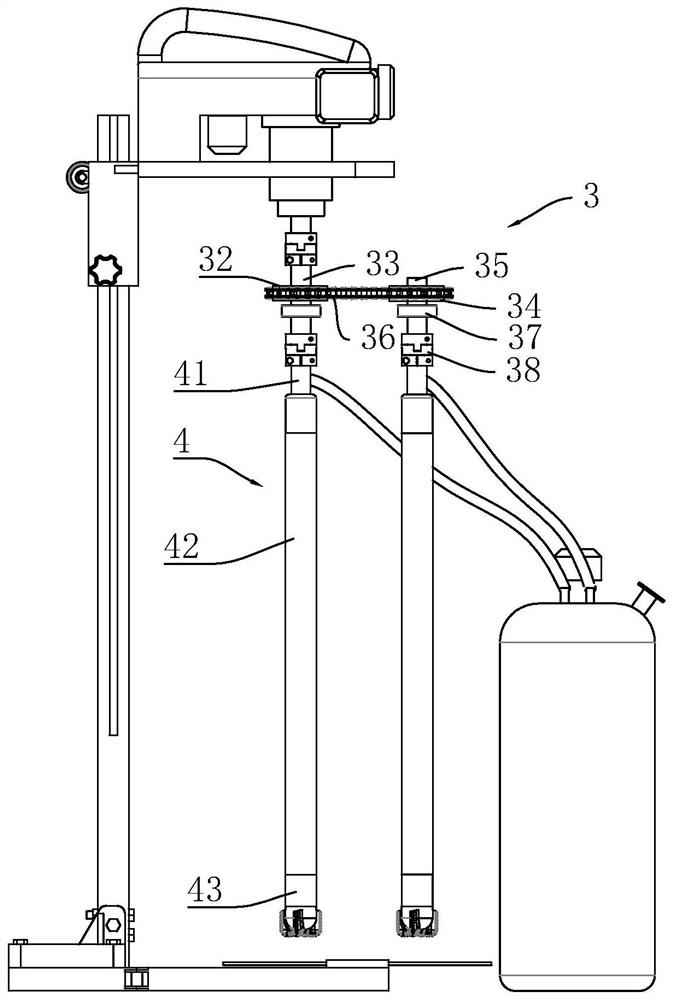

[0053] like figure 1 As shown, a high-efficiency rock and soil sampling device includes a fixed bracket assembly 1, a gasoline engine 2, a transmission assembly 3, and a drilling assembly 4 that are installed on the fixed bracket assembly 1 and connected in sequence, and between the gasoline engine 2 and the fixed bracket assembly 1. A sliding assembly 5 is also connected between them, allowing the gasoline engine 2 to move up and down along the fixed bracket assembly 1. The drilling assembly 4 is externally connected with a water cooling system 6 .

[0054] like figure 1 As shown, the fixed bracket assembly 1 includes a vertical sliding bar 11 and a base bracket 12 installed at the bottom of the vertical sliding bar 11 . A slideway 111 is provided on the vertical slide bar 11 for a slide assembly 5 to slide along it in the future. In order to maintain balance, a counterweight 112 is provided at the bottom of the vertical slide bar 11 in the direction away from the gasoline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com