Method for checking damage of metal part and device thereof

A technology of inspection device and inspection method, which is applied to measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. To solve problems such as detection and signal disorder, to achieve the effect of simple structure, intuitive effect, and reducing the interference of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A metal damage inspection method is provided. The metal has a flat surface. The metal is placed horizontally, and a sphere that can freely fall on the flat surface of the metal is set along a vertical path. There are two reference values, the decibel value and the number of times the sphere touches the metal part. By comparing the two reference values with the corresponding standard value, it is possible to distinguish whether there is damage in the metal part. According to the comparison between these reference values and the standard value The degree of difference can also determine the size of the damage.

[0029] In order to further assist in confirming the damage, the vibration frequency and vibration displacement parameters of the metal part can also be collected at the position where the ball and the metal part touch, and compared with the corresponding standard values.

Embodiment 2

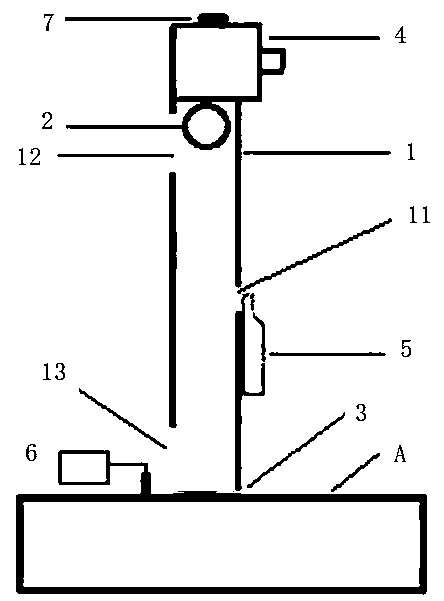

[0031] A device for inspecting damage to metal parts. The metal parts in this embodiment take steel rails as an example, such as figure 1 As shown, the damage inspection device includes a linear guide tube 1 perpendicular to the flat surface of the rail A, a sphere 2 is placed in the guide tube 1, the diameter of the sphere 2 is slightly smaller than that of the guide tube 1, and both the guide tube 1 and the sphere 2 are made of magnetic The first end of the guide tube 1 is detachably connected to the rail A through a ring magnet 3. The ring magnet 3 can firmly attract the guide tube 1 to the rail A to ensure the stability of the guide tube 1. , the second end of the guide tube 1 is placed with an electromagnet 4 that can be attracted and separated from the sphere 2, and the electromagnet 4 is controlled by a corresponding switch (the on-off control of the electromagnet belongs to the prior art, here Not to be described in detail), the sphere 2 can be separated from the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com