Acousto-optic leakage monitoring system for nuclear power plant main steam pipeline

A technology of monitoring system and main steam, which is applied in the field of leakage monitoring system and can solve the problems of long response time, poor positioning and quantification accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

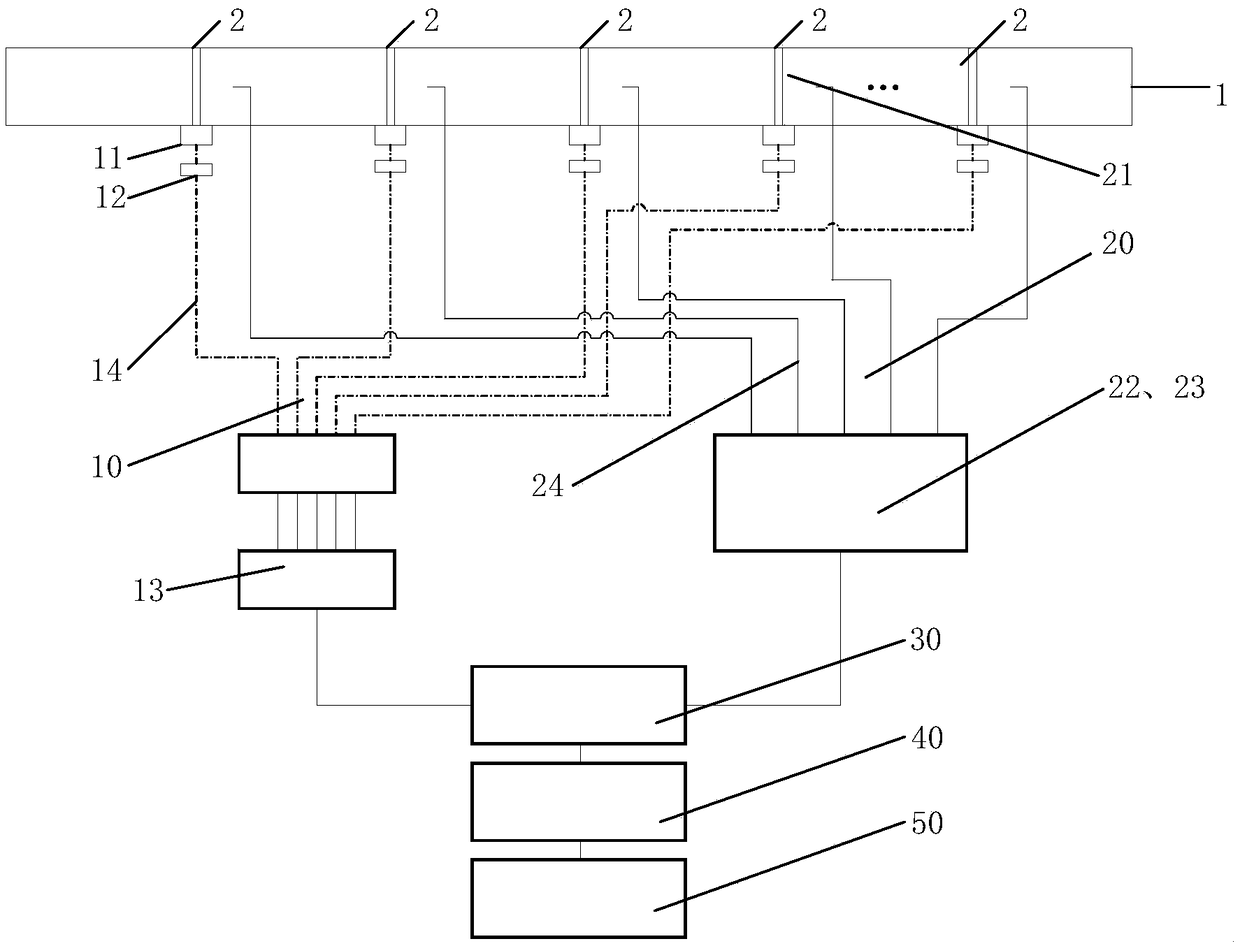

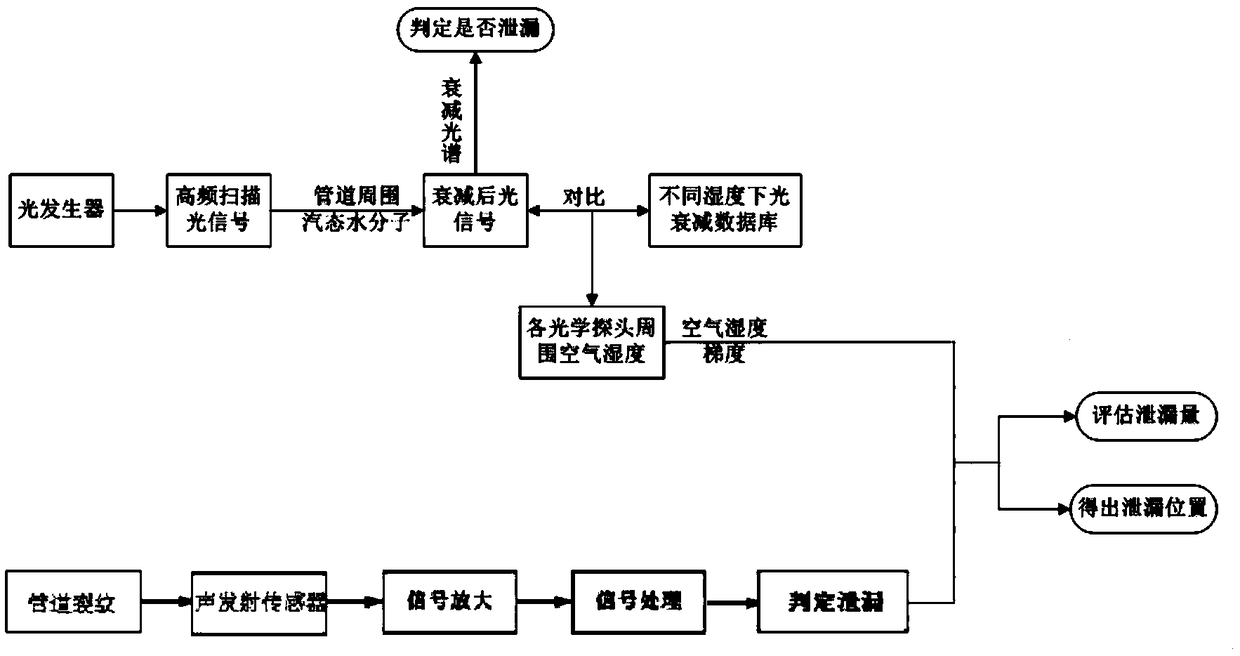

[0025] Such as figure 1 and figure 2 As shown, the acousto-optic combined leakage monitoring system for the main steam pipeline of a nuclear power plant of the present invention realizes the diversity and redundancy of the main steam pipeline leakage monitoring, and it includes an acoustic emission leakage monitoring circuit 10 and a spectral leakage monitoring circuit 20, and the acoustic emission leakage monitoring circuit 20 The signal input end of the emission leakage monitoring circuit 10 and the signal input end of the spectral leakage monitoring circuit 20 are respectively arranged at the detection point 2 of the main steam pipeline 1, and the signal output end of the acoustic emission leakage monitoring circuit 10 and the signal output of the spectral leakage monitoring circuit 20 The terminals are communicatively connected to each other through a network switch 30, and the network switch 30 is sequentially connected with a control unit 40 and a display unit 50.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com