Zero-energy automatic sewage disposal unit for prawn breeding pond

A breeding pond, automatic cleaning technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of dirt accumulation and low speed in the center of the pond, so as to speed up the cleaning process, speed up the rotation speed, and improve the cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

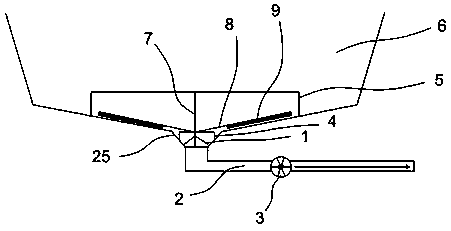

[0026] Such as Figure 1-6 Shown, the scheme that the present invention takes for realizing the above object is: a kind of zero-energy consumption prawn cultivation pond automatic cleaning device, comprises cultivation pond 6, and the bottom of cultivation pond 6 is provided with blowdown outlet 25, and the top of blowdown outlet 25 is provided with turbine 1. A turbine cover 4 is provided above the turbine 1, and a connecting shaft 7 is provided on the upper end of the turbine 1 to pass through the turbine cover 4 to flexibly connect to the inside of the escape cover 5. A connecting rod 8 is provided on both sides of the connecting shaft 7, and a scraper is arranged on the connecting rod 8. slice 9. The sewage outlet set at the bottom of the breeding pond is convenient for the discharge of breeding sewage. There is a turbine above the sewage outlet. When the sewage is discharged, the power of the water flow drives the turbine, and then drives the connecting rods on both sides...

Embodiment 2

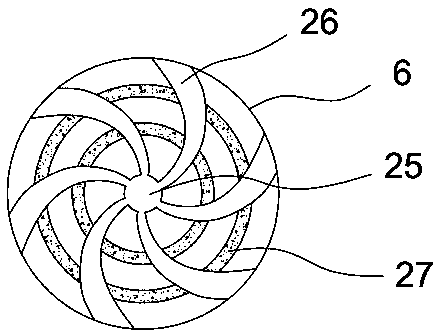

[0033] Such as Figure 7-8 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the surface of the turbine cover 4 is evenly distributed with water filter sheets 14 with curved inner surfaces, and the upper and lower ends of the water filter sheet 14 are connected with inwardly folded Splitter 16. The evenly distributed inner surface of the turbine cover is a curved water filter, which can make the water flowing into the turbine cover generate a larger and faster water flow vortex when it follows the curved inner surface of the water filter. The inwardly folded splitter connected to the upper and lower ends of the water sheet can generate multiple streams of water flowing into the turbine cover and re-converge in the turbine cover, making the rotational force generated by the water flow stronger and larger, greatly improving the internal The speed of the turbine blades speeds up the cleaning process.

[0034] Turbine blades 18 are evenly dist...

Embodiment 3

[0037] The working principle of the zero-energy prawn breeding pond automatic cleaning device of the present invention is as follows: open the sewage outlet 25 to discharge sewage, and under the impact of the water flow, the turbine blade 18 is rotated under the impact of the water flow, thereby driving the connection with the turbine 1 The connecting shaft 7 rotates, so that the connecting rod 8 and the scraper 9 make a circular motion at the bottom of the culture pond 6, and drive the water at the bottom of the pond near the center of the pond to flow to form a circulation, thereby collecting the dirt to the center of the pond, and at the bottom of the water pump 3 Under the action, the sewage in the center of the pool is discharged from the sewage pipe 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com