Advanced sewage deep treatment system

A technology for advanced treatment and sewage, applied in chemical/physical processes, mixers with rotating containers, dissolution, etc., can solve problems such as low mixing efficiency, high labor intensity, and high difficulty, and achieve improved mixing efficiency and improved mixing effect , the effect of rapid stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

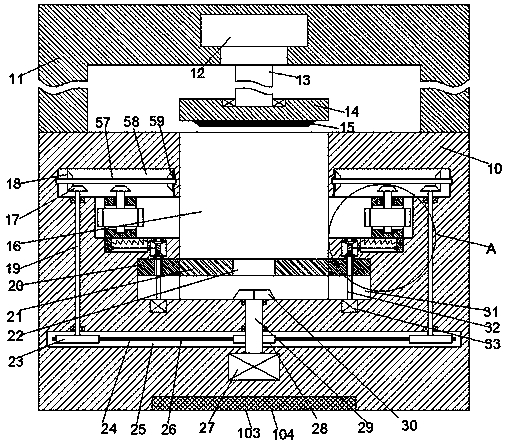

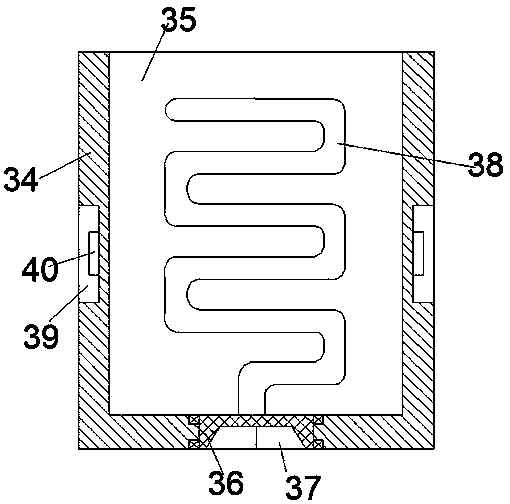

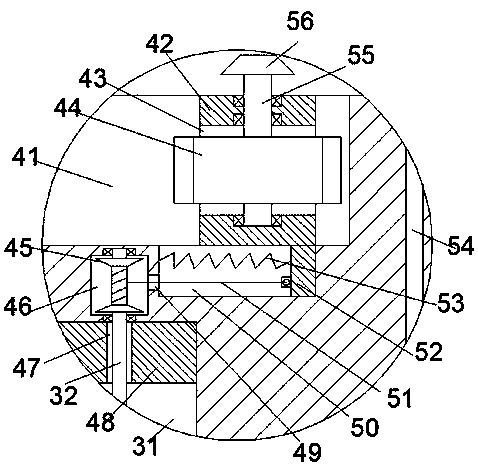

[0019] Such as Figure 1-3 As shown, an advanced advanced sewage treatment system of the present invention includes a frame 10 and a mixing drum 34. The top end surface of the frame 10 is provided with an installation cavity 16 with an upward opening, and the inner walls of the left and right sides of the installation cavity 16 are A first sliding groove 41 is symmetrically arranged in the center, and a first sliding block 42 is slidably installed in the first sliding groove 41. A first through groove 43 penetrating left and right is provided in the first sliding block 42. The first The first rotating shaft 55 is rotatably installed in the upper and lower end walls of the through groove 43, and the rotating gear 44 is fixedly arranged on the first rotating shaft 55. A rotating chamber 58, the top extension end of the first rotating shaft 55 extends into the first rotating chamber 58 and the top end is fixed with a first bevel gear 56, and the left and right end walls of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com