Method for degrading endosulfan through mechano-chemical process

A mechanochemical method, endosulfan technology, applied in the restoration of contaminated soil, grain treatment, etc., can solve the problems of rare mechanochemical degradation research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

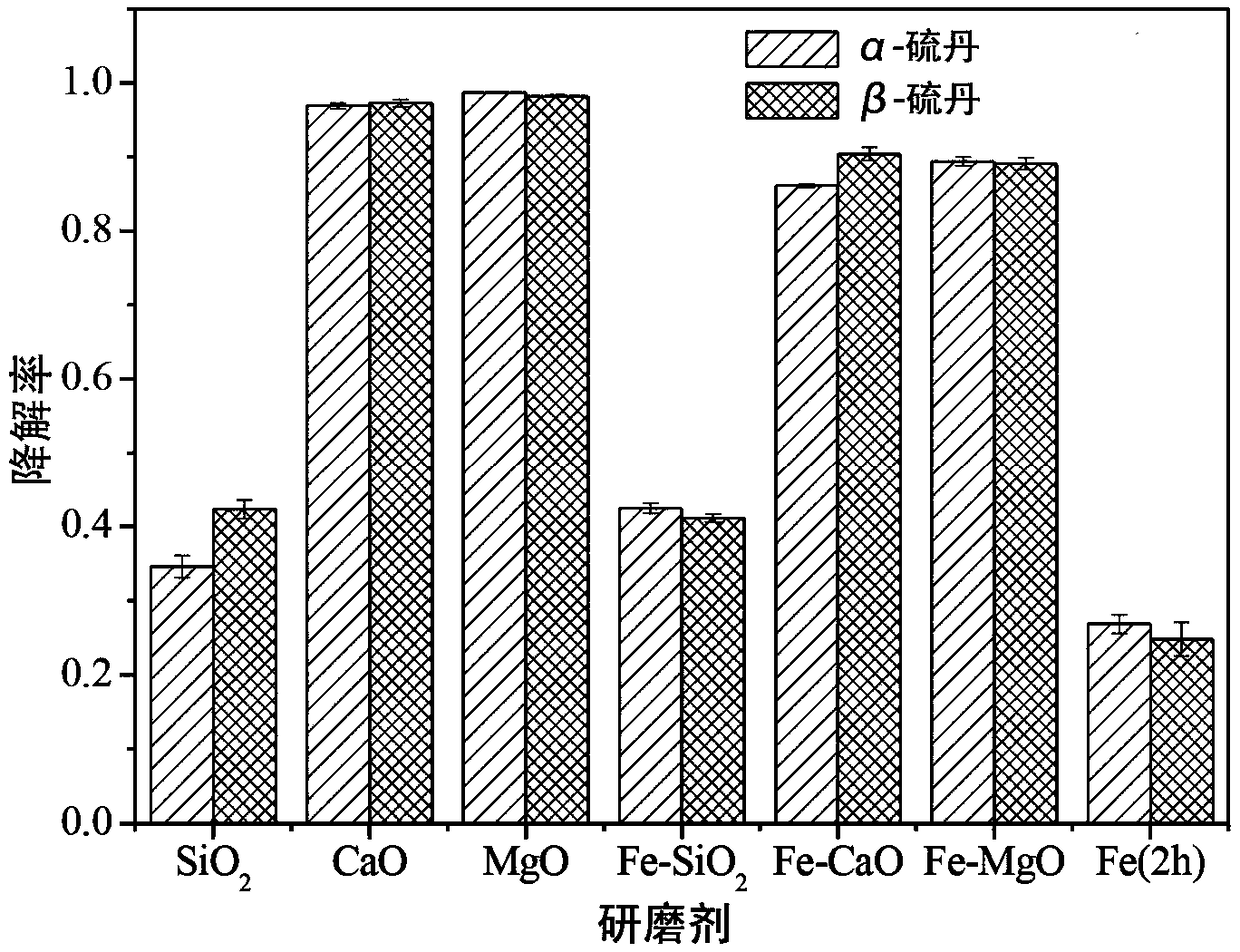

[0033] A method for degrading endosulfan using a mechanochemical method, the ball milling speed is 520rpm, the material ratio is 20:1, the ball-to-material ratio is 20:1, the mass of iron balls is 120g, and the ball mill is rotated for 30 minutes and immediately reversed for 30 minutes, and so on; After ball milling, the degradation rate of endosulfan was determined; wherein, the abrasives were CaO, MgO, SiO 2 , CaO: Fe powder = 1: 1 (mass ratio), MgO: Fe powder = 1: 1 (mass ratio), SiO 2 : Fe powder=1:1 (mass ratio), ball milled for 30min.

[0034] figure 1 For the comparison of the degradation efficiency of endosulfan ball milling for 30min between various abrasives and different combinations, from figure 1 It can be seen that when ball milling for 30min, the degradation rate of endosulfan by MgO and CaO is the highest, followed by the combination of iron powder and MgO and CaO (mass ratio 1:1), and the other efficiencies are all no more than 50%, especially When Fe powde...

Embodiment 2

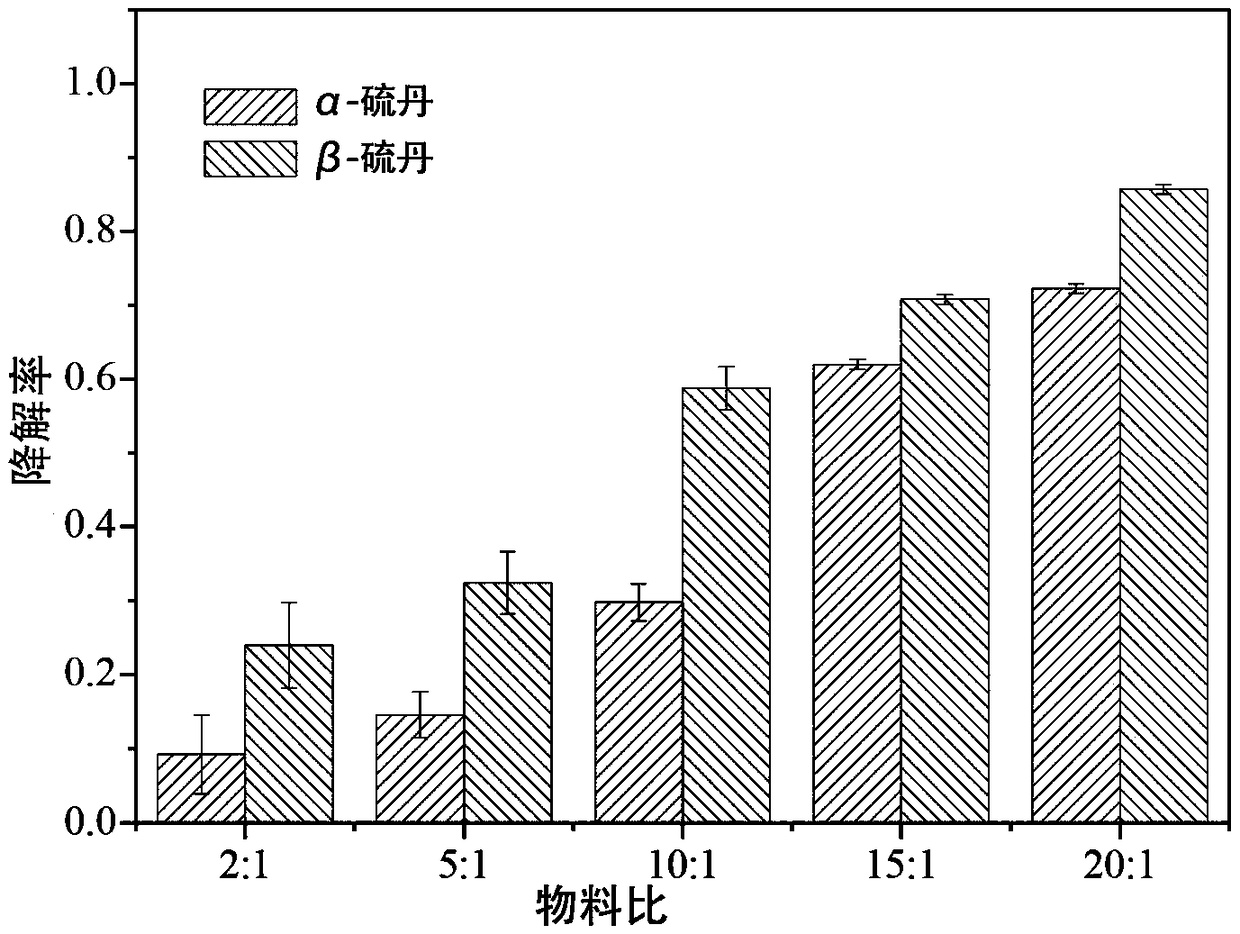

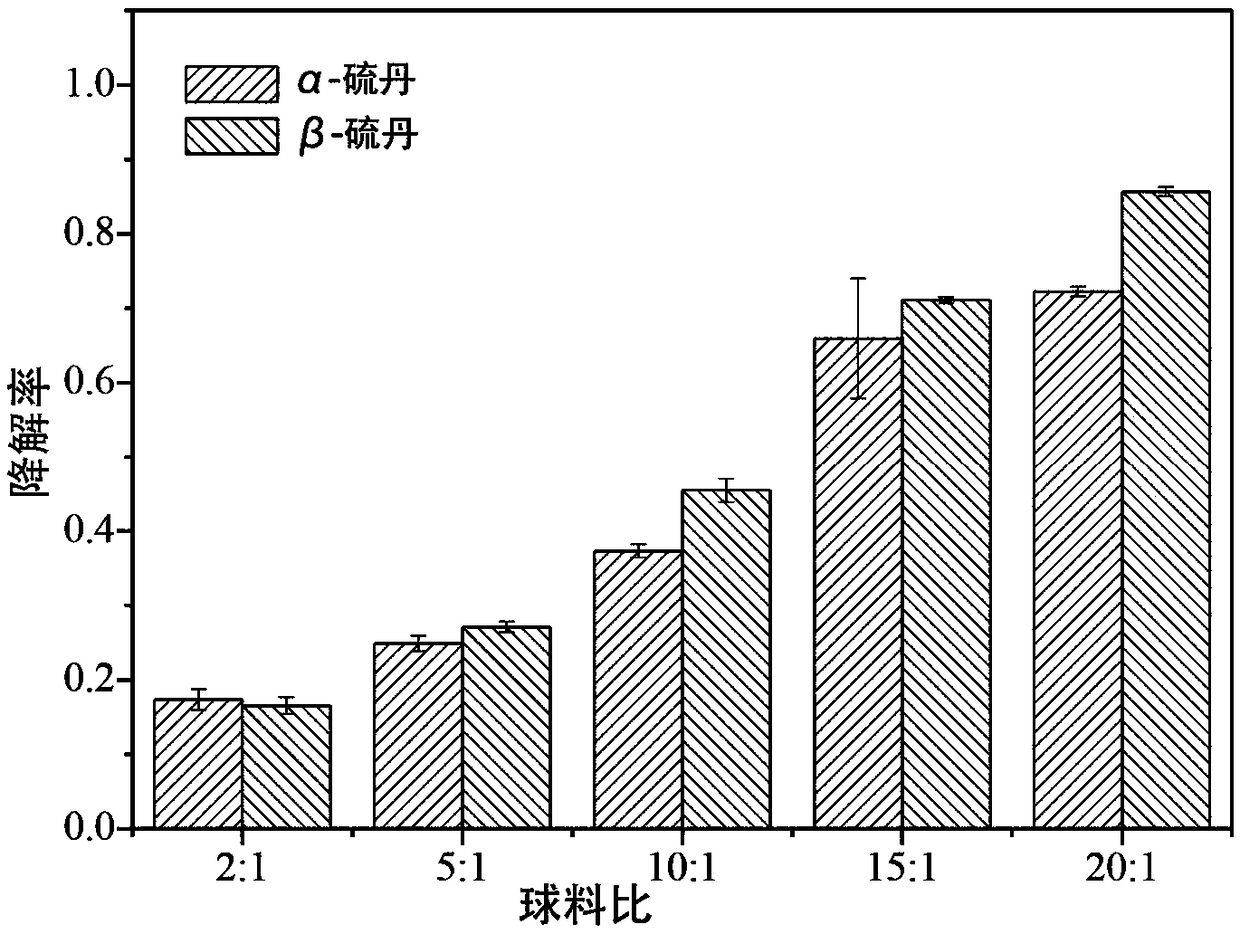

[0036] A method for degrading endosulfan using a mechanochemical method is the same as in Example 1, wherein the grinding agent is CaO. 1) The ball milling speed is 100rpm, 200rpm, 300rpm, 400rpm, 500rpm, respectively, 2) The ball milling time is 15min, 30min, 60min, 90min, 120min, 3) The material ratio is 2:1, 5:1, 10:1, 15 : 1, 20: 1; 4) The ball-to-material ratio is 2: 1, 5: 1, 10: 1, 15: 1, 20: 1.

[0037] figure 2 , image 3 and Figure 4 The effect of different ball milling conditions on the degradation rate of endosulfan was ball milled for 30 minutes. The test process adopts the control variable method. It can be seen from the figure that material ratio, pellet ratio and rotational speed have a great influence on the degradation rate of endosulfan. With the increase of material ratio, ball-to-material ratio and rotational speed, the degradation rate of endosulfan increased and showed a continuous upward trend. This shows to a certain extent that high material ra...

Embodiment 3

[0038] Embodiment 3 degrades soil test containing endosulfan

[0039] The soil was taken from the back hill of Nanjing Forestry University. After the soil is dried, ground, sterilized and dried, it passes through 40 meshes, and the technical endosulfan is added. After ball milling, the residual amount of endosulfan is measured and the removal efficiency of endosulfan is calculated.

[0040] The ratio of soil and endosulfan technical is 100:1, first dissolve 1.0000g endosulfan in 50mL acetone solution to make endosulfan-acetone solution with a concentration of 20g / L; sprinkle 50mL endosulfan-acetone solution evenly on 100g In the pretreated soil, thoroughly mix the endosulfan solution and the soil. Properly heat and stir to volatilize the acetone until the soil is re-dried, and take random samples to measure the final total content of endosulfan in the soil. Take five groups of 10g endosulfan-containing soil, add about 0.7g CaO (the mass ratio of calcium oxide to endosulfan is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com