Embedded type pulling core used by automobile door lock sleeve die-casting die

A technology of die-casting molds and automobile door locks, which is applied in the field of embedded core pulling, and can solve the problems of unfavorable large-scale batch production, poor consistency of design, process and product assembly, and complex structure of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0022] Embodiments of the invention

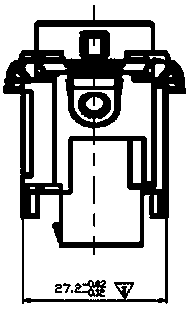

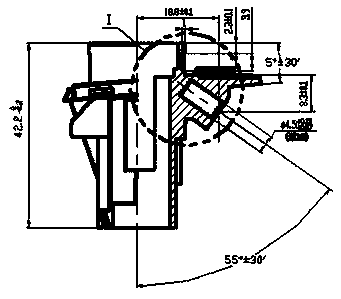

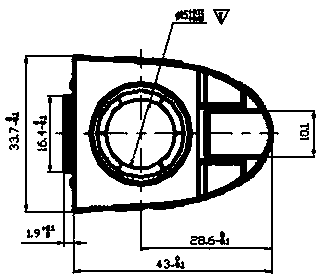

[0023] An embedded core-pulling used in the die-casting mold of an automobile door lock sleeve, as attached Figure 5 As shown, the main slideway 29 is included, and one side of the main slideway 28 is provided with an embedded chute 31 at an angle of 35° with the main slideway 29. The embedded chute 31 is connected with an embedded core-pulling slider 45, which is inserted into the core-pulling slider 45. One side of the core slider 45 is fixedly connected with the bottom hole core 42 via the mounting pin 44; one side of the embedded chute 31 is provided with a pit core-pulling slider 27, and the pit core-pulling slider 27 is close to the bottom hole core 42 One side is provided with pit core-pulling 1 43, and the side of pit core-pulling slider 27 near embedded core-pulling slider 45 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap