PLC (programmable logic controller) control-based screw driving skating blade sharpening device

A lead screw and blade technology, which is used in grinding automatic control devices, grinding drive devices, moving accessories, etc., can solve the problems of non-adjustable movement stroke and movement trajectory, inability to achieve precise control, and high price, and achieve a compact structure. , Simple structure, low cost effect

Pending Publication Date: 2018-12-28

JILIN UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. Devices with a low degree of automation mostly use rotating grinding wheels to grind the blade, which has low precision, non-adjustable motion stroke and trajectory, and cannot achieve precise control and high energy consumption; 2. The algorithm with a high degree of automation is complex, difficult to operate, and expensive Expensive, 3. Poor versatility

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

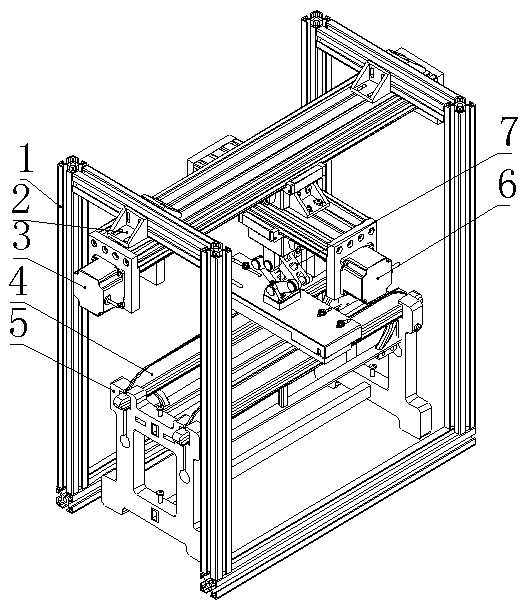

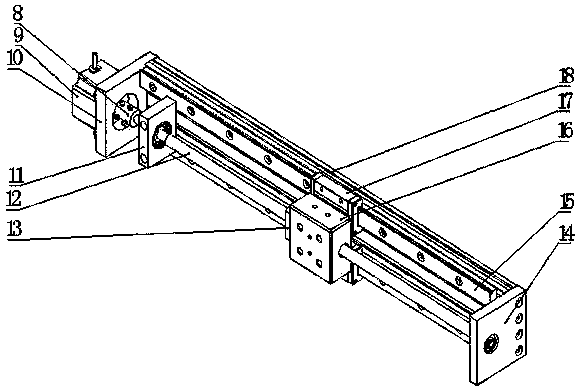

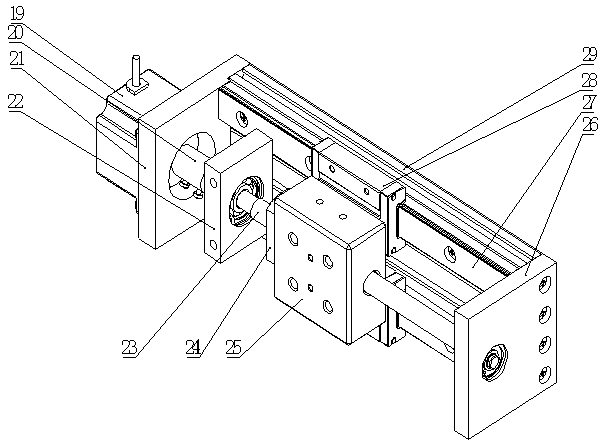

The invention relates to a PLC control-based screw driving skating blade sharpening device and belongs to the field of sports equipment. The PLC control-based screw driving skating blade sharpening device is mainly composed of a support, a skating blade rack, three branch motion chains and an oilstone, wherein the three branch motion chains are in an X direction, a Y direction and a Z direction respectively, and the X-directional branch motion chain and the Y-directional branch motion chain are identical in structure and are respectively composed of a ball screw nut pair and a linear guide rail; the X-directional branch motion chain is fixed onto the slider of the Y-directional branch motion chain to achieve motion inside an XOY plane; in the Z-direction, the oilstone moves along with theshape change of a skating blade. The PLC control-based screw driving skating blade sharpening device has the advantages of being compact in structure, novel in conception, convenient to use, easy to maintain, good in assembling property and high in practicality, and can set an oilstone motion track as required to help acquire ideal blade surface roughness and cross-shaped surface texture, therebybeing applicable to daily grinding maintenance of the skating blade.

Description

technical field The invention relates to the field of sports equipment, in particular to a speed skating blade sharpening device, in particular to a PLC-based screw driven ice blade sharpening device. Background technique Ice skates are the main sports equipment for ice sports. The surface finish and cross texture of the blade affect the friction force, which in turn affects the speed of movement, and even determines the athlete's competition performance. At present, most of the existing domestic skate sharpening devices are manual or semi-automatic skate sharpening devices, and the limitations of manual devices are self-evident. Now emphatically set forth the limitations of the semi-automatic skate sharpening device with a typical inventive device. The control system of the portable CNC ice skate grinding machine developed by the Heilongjiang Provincial Institute of Sports Science is complex in programming, difficult to operate, expensive, and the surface texture of the b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B3/00B24B41/02B24B47/04B24B51/00

CPCB24B3/003B24B41/02B24B47/04B24B51/00

Inventor 王昕葛俊亮程悦李春爽陈锐

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com