Glue sealing end face glue cutting equipment

A technology of equipment and end face, which is applied in the field of sealing and end face cutting equipment, can solve the problems affecting the cutting efficiency, maintenance cost and service life of the equipment, inconvenient cleaning of the equipment, easy aging and other problems, and achieve simple and convenient cleaning and operation, and beautiful appearance. , easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

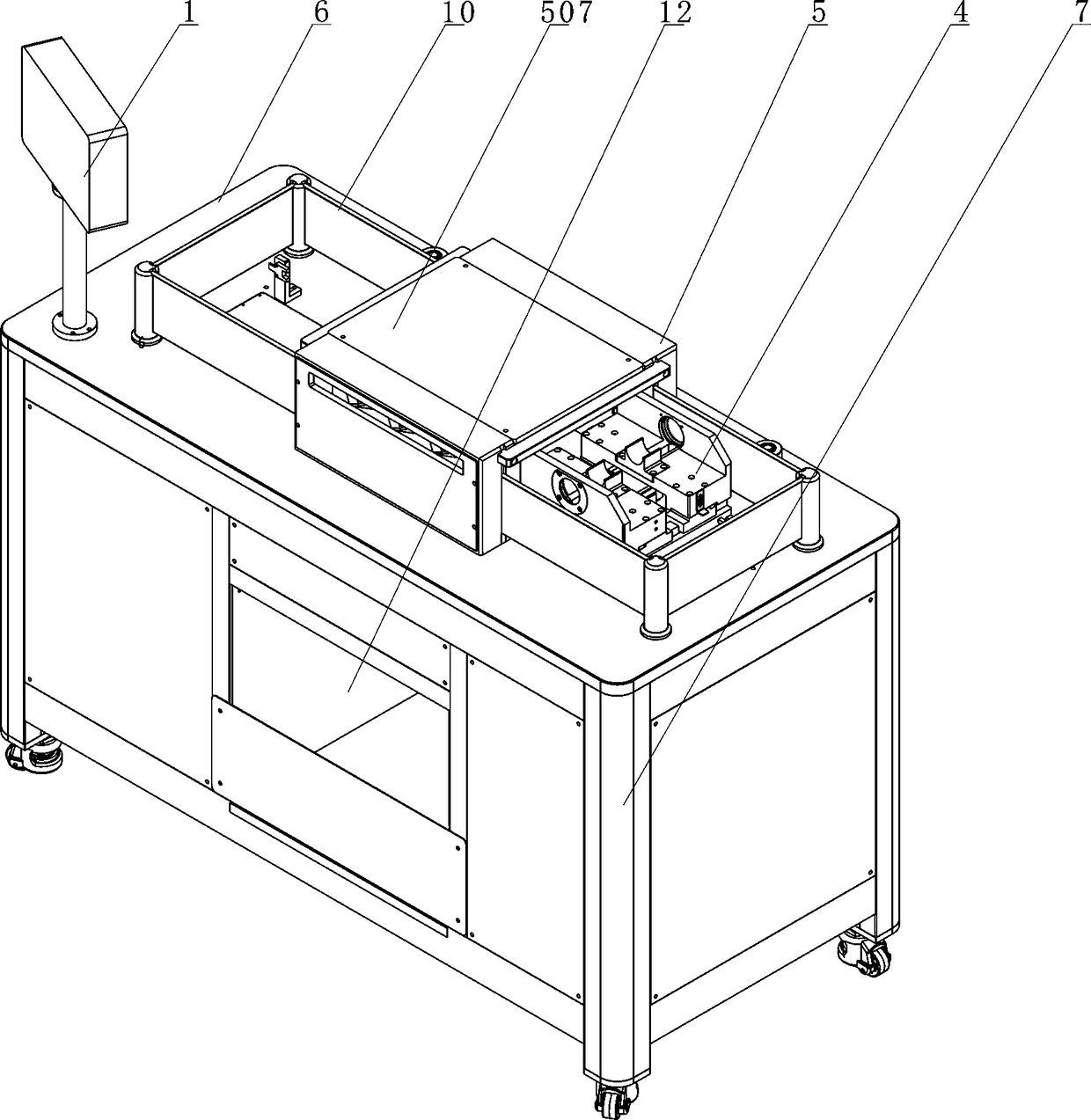

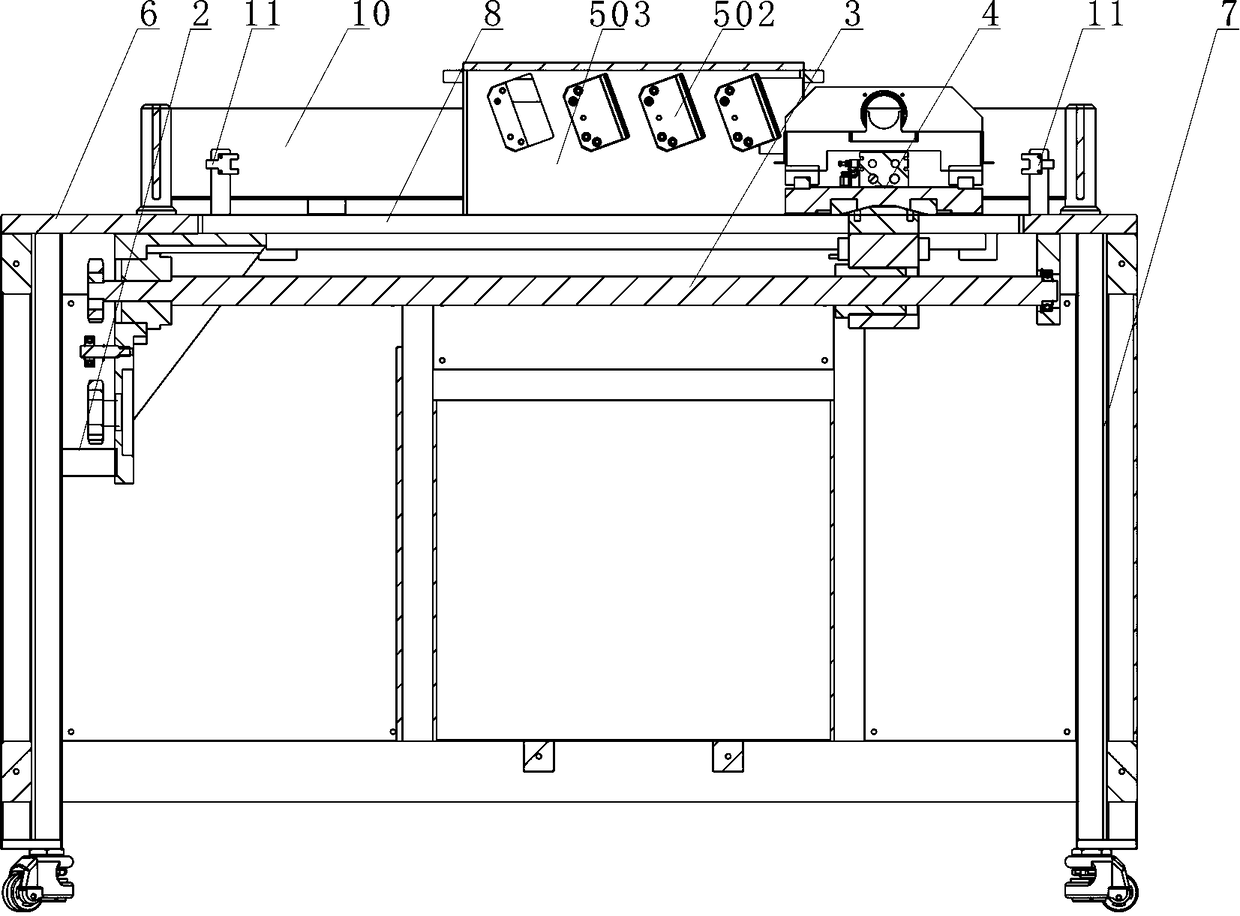

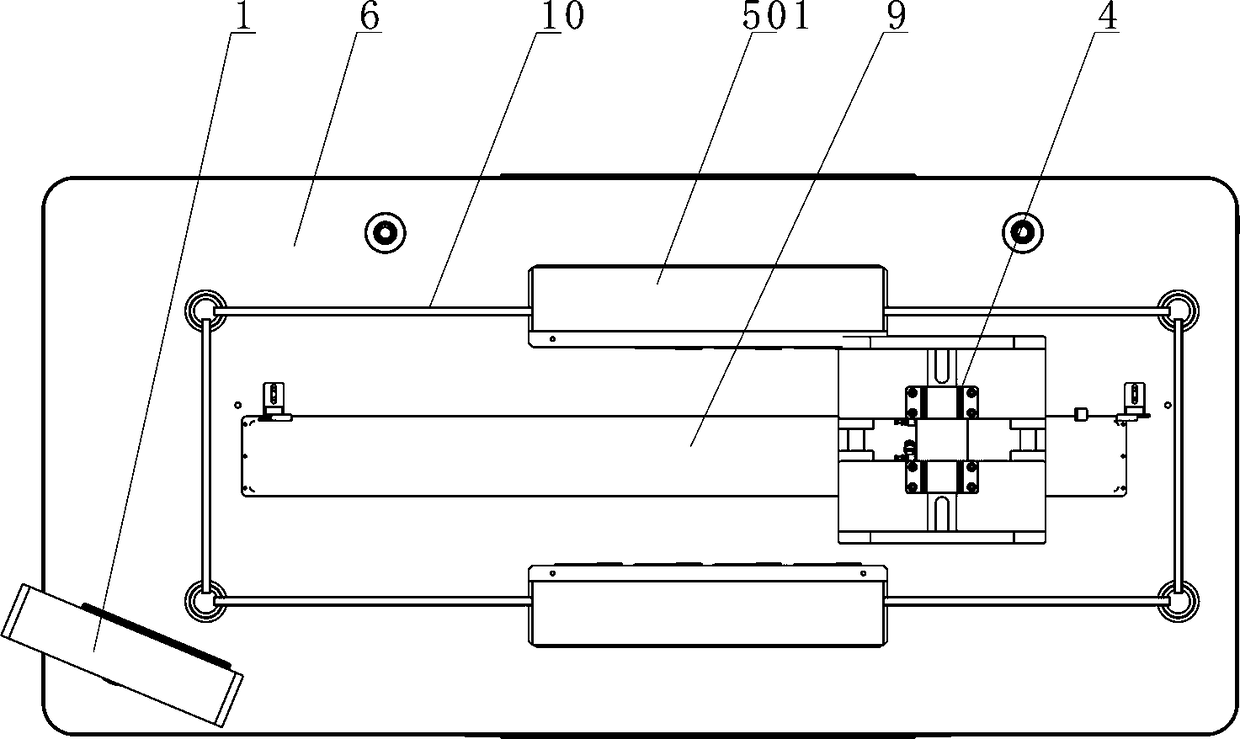

[0043] Such as Figure 1-10 As shown: the present invention is a glue sealing end surface cutting equipment, and its main core components are control system 1, motor 2, transmission mechanism 3, clamping mechanism 4 and cutter assembly 5. Among them, the control system 1 is connected with the motor 2, the transmission mechanism 3, the clamping mechanism 4 and the cutter assembly 5 to complete the automatic control of these functional accessories, mainly to control the work of the motor 2, the position adjustment of the cutter assembly 5, and the clamping mechanism 4 reciprocating motion, etc. The motor 2 is connected to the transmission mechanism 3 to provide power for it. The clamping mechanism 4 is used to fix the installation position of the workpiece, which adopts an automatic centering mechanical structure, so that after the workpiece is mounted on it, the two ends of the clamping mechanism 4 move closer to the center with the center as a fixed point, thereby realizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com