Preparation method of synthetic wood

A technology for synthesizing wood and wood powder, applied in the field of synthetic wood preparation, can solve the problems of high production cost, short service life, fast aging, etc., and achieve the effects of reducing the use of wood, long service life, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

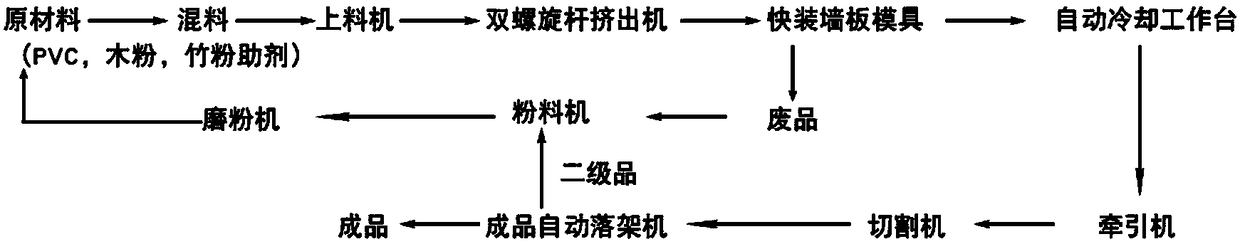

[0027] see figure 1 , in the embodiment of the present invention, a kind of preparation method of synthetic wood comprises the following steps:

[0028] S1. Preparations before starting the machine. First, check whether the water, electricity, and air of the extruder are normal. The water includes the cooling water inside the extruder, whether the water supply of the water pump is normal, and whether the cooling water of the equipment setting table is normal; electricity includes: extrusion Whether the temperature control of the machine is normal, whether the setting table moves forward and backward, the motor of the tractor rotates, whether the cutting saw is normal, etc.; the gas includes: whether the pressure of the copying machine, the cutting saw, and the tractor are normal;

[0029] S2. Put stabilizer, acid, PE wax, foaming agent, foam regulator, wood powder, and pigment in a container to form a small material, and then add PVC resin, CaCa, and gusset grinding powder to ...

Embodiment 2

[0039] see figure 1 , in the embodiment of the present invention, a kind of preparation method of synthetic wood comprises the following steps:

[0040] S1. Preparations before starting the machine. First, check whether the water, electricity, and air of the extruder are normal. The water includes the cooling water inside the extruder, whether the water supply of the water pump is normal, and whether the cooling water of the equipment setting table is normal; electricity includes: extrusion Whether the temperature control of the machine is normal, whether the setting table moves forward and backward, the motor of the tractor rotates, whether the cutting saw is normal, etc.; the gas includes: whether the pressure of the copying machine, the cutting saw, and the tractor are normal;

[0041] S2. Put stabilizer, acid, PE wax, foaming agent, foam regulator, wood powder, and pigment in a container to form a small material, and then add PVC resin, CaCa, and gusset grinding powder to ...

Embodiment 3

[0051] see figure 1 , in the embodiment of the present invention, a kind of preparation method of synthetic wood comprises the following steps:

[0052] S1. Preparations before starting the machine. First, check whether the water, electricity, and air of the extruder are normal. The water includes the cooling water inside the extruder, whether the water supply of the water pump is normal, and whether the cooling water of the equipment setting table is normal; electricity includes: extrusion Whether the temperature control of the machine is normal, whether the setting table moves forward and backward, the motor of the tractor rotates, whether the cutting saw is normal, etc.; the gas includes: whether the pressure of the copying machine, the cutting saw, and the tractor are normal;

[0053] S2. Put stabilizer, acid, PE wax, foaming agent, foam regulator, wood powder, and pigment in a container to form a small material, and then add PVC resin, CaCa, and gusset grinding powder to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com