Textile printing and dyeing wastewater treatment system

A wastewater treatment system, textile printing and dyeing technology, applied in textile industry wastewater treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the difficulty of cleaning the sludge in the lower hopper and increase the workload of workers and other problems to achieve the effect of avoiding blockage

Inactive Publication Date: 2018-12-28

张兴宇

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the traditional textile printing and dyeing wastewater treatment system uses a sewage desilter to treat the wastewater, after the wastewater and the sludge are separated, the sludge is discharged and accumulated inside the holding container, and the accumulated sludge needs to be manually pushed evenly, which increases the The workload of the workers is increased, and the sludge located on the inner wall of the lower hopper is difficult to clean

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

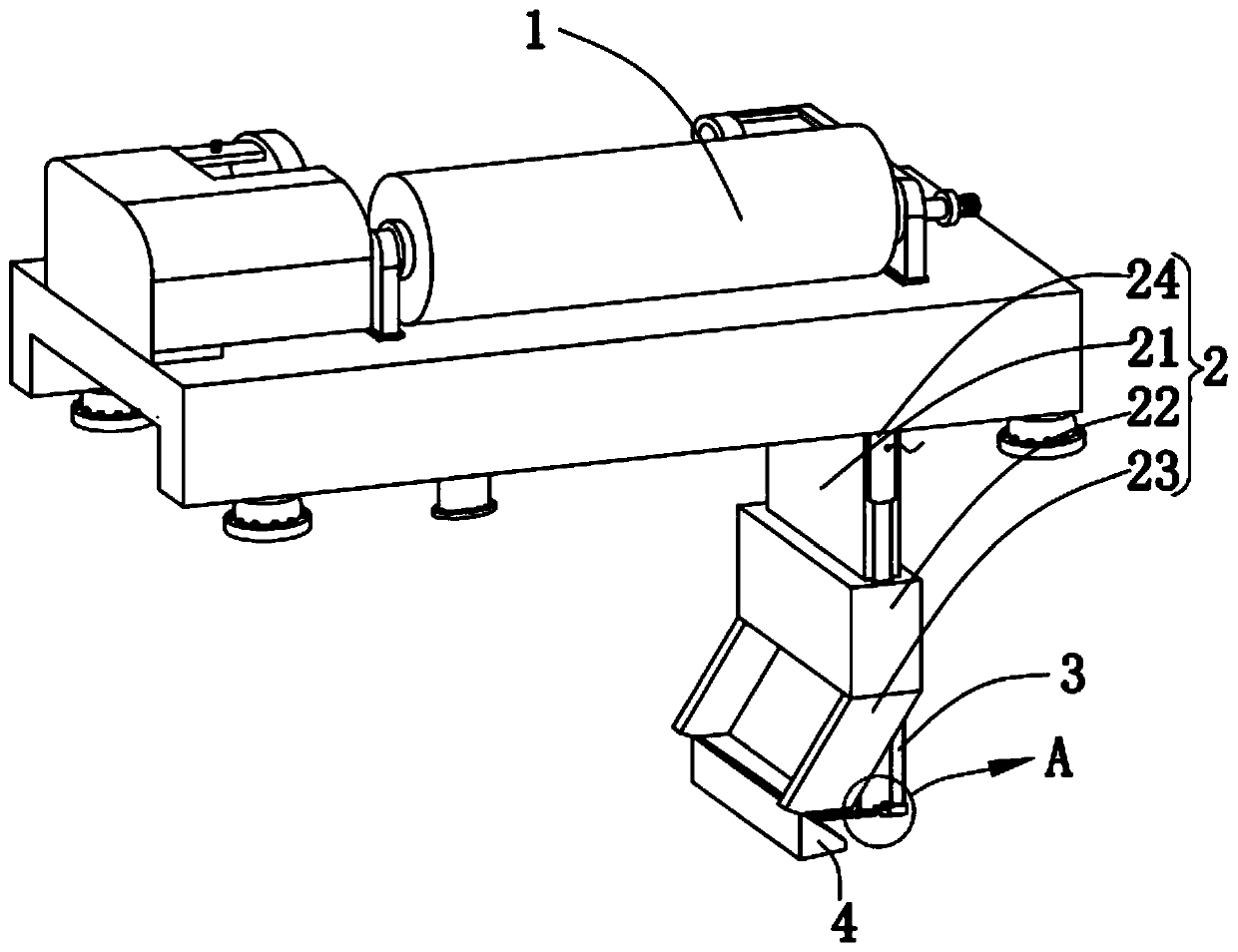

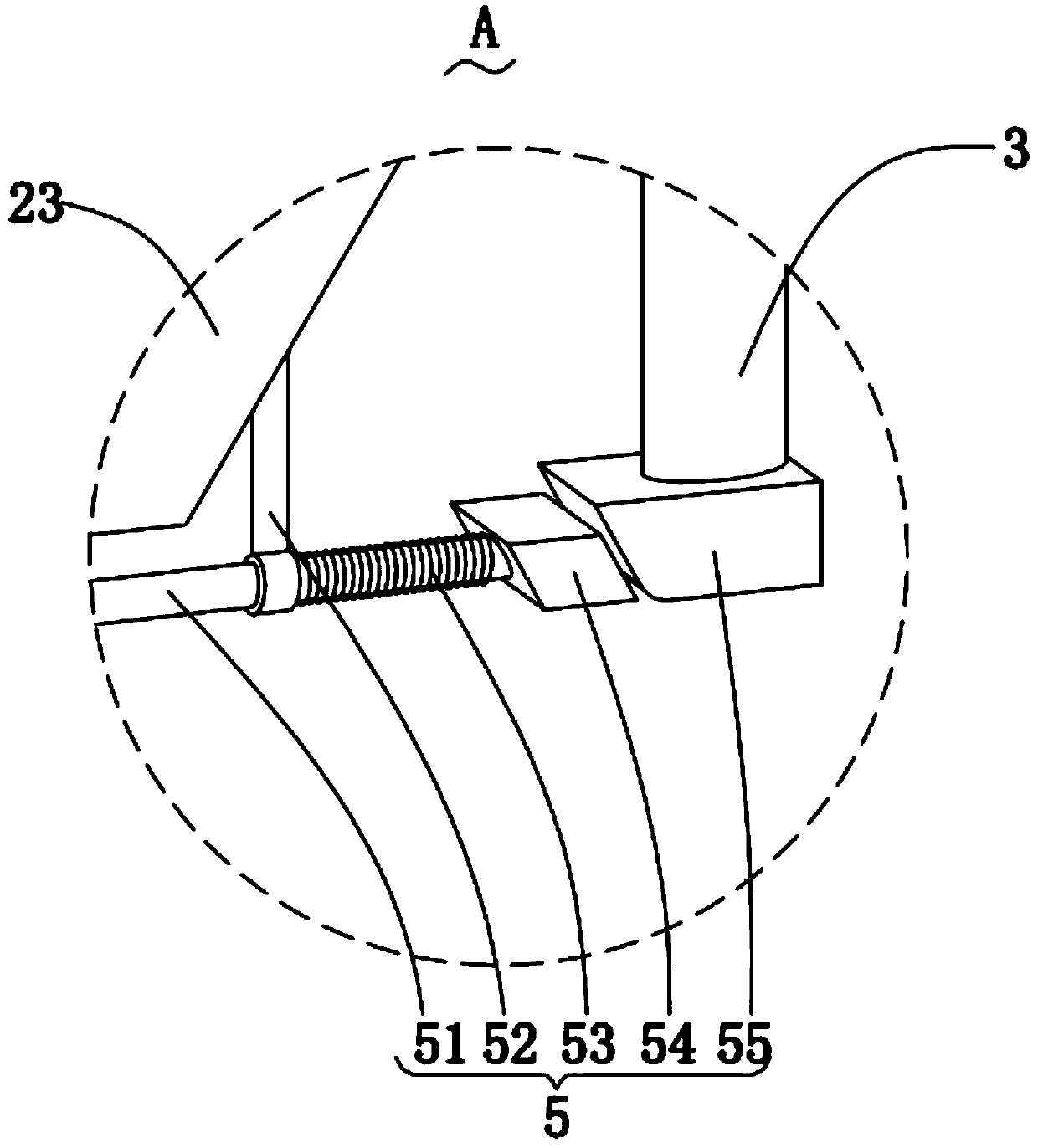

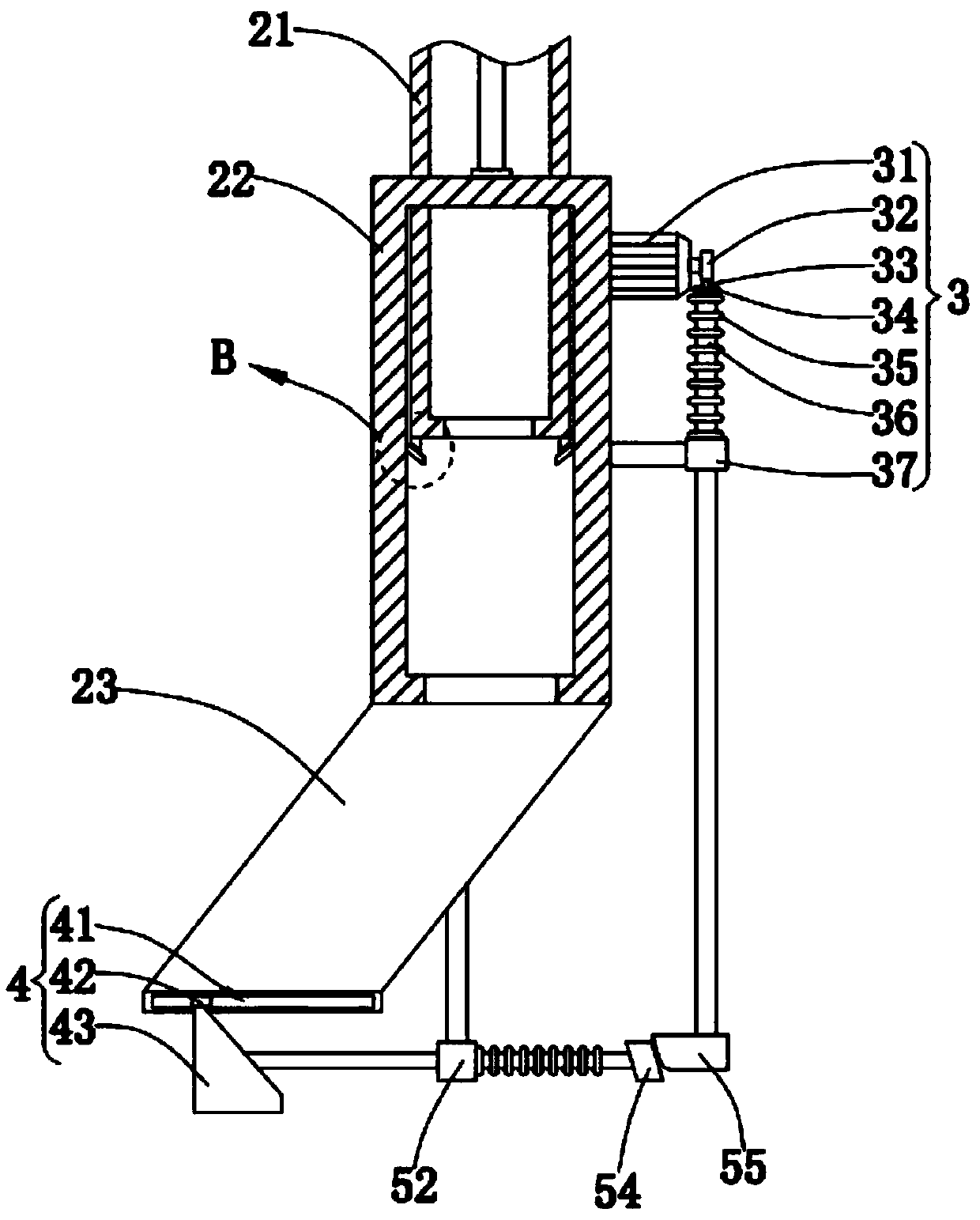

The invention relates to the field of textile printing and dyeing wastewater treatment, in particular to a textile printing and dyeing wastewater treatment system. The system comprises a sewage sludgeremoving machine, a discharging mechanism, a driving mechanism, a sludge pushing mechanism, a link mechanism and a sludge scraping mechanism, wherein the bottom of the sewage sludge removing machineis communicated with a discharging pipe used for discharging sludge; an electric drive pusher fixed with top of a connecting cylinder is mounted on the side wall of the discharging pipe; stretching and retraction of the electric drive pusher cooperate with placement of a sludge container, height of the electric drive pusher is adjusted according to the amount of sludge in the sludge container, anda drainage hopper is prevented from being blocked; the driving mechanism is mounted on the side wall of the connecting cylinder, a motor is powered on during beating of sludge, the link mechanism isbeaten by the driving mechanism, further, the sludge pushing mechanism is enabled to flatten sludge pushed and extruded together in the sludge container, and the defect of traditional manual pushing is overcome.

Description

technical field The invention relates to the field of textile printing and dyeing wastewater treatment, in particular to a textile printing and dyeing wastewater treatment system. Background technique Printing and dyeing is also called dyeing and finishing. It is a processing method, and it is also a general term for pretreatment, dyeing, printing, finishing, washing, etc.; the undergraduate dyeing and finishing major has now been incorporated into the light chemical engineering major, and the sludge dewatering machine is a continuous operation of sludge treatment. The equipment has a low moisture content in the mud, stable operation, low energy consumption, relatively simple control and management, and convenient maintenance. However, when the traditional textile printing and dyeing wastewater treatment system uses a sewage desilter to treat the wastewater, after the wastewater and the sludge are separated, the sludge is discharged and accumulated inside the holding conta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/12C02F103/30

CPCC02F11/121C02F2103/30

Inventor 张兴宇张家俊陈浩

Owner 张兴宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com