Coating-free glass fiber reinforced PBT/PET composition having metal effect and preparation method thereof

A metal effect and composition technology, which is applied in the field of non-spraying metal effect glass fiber reinforced PBT/PET composition and its preparation field, can solve the problems of long molding cycle, brittle bakelite, inconvenient production and processing, etc., and can improve the surface metal effect. , the effect of excellent mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

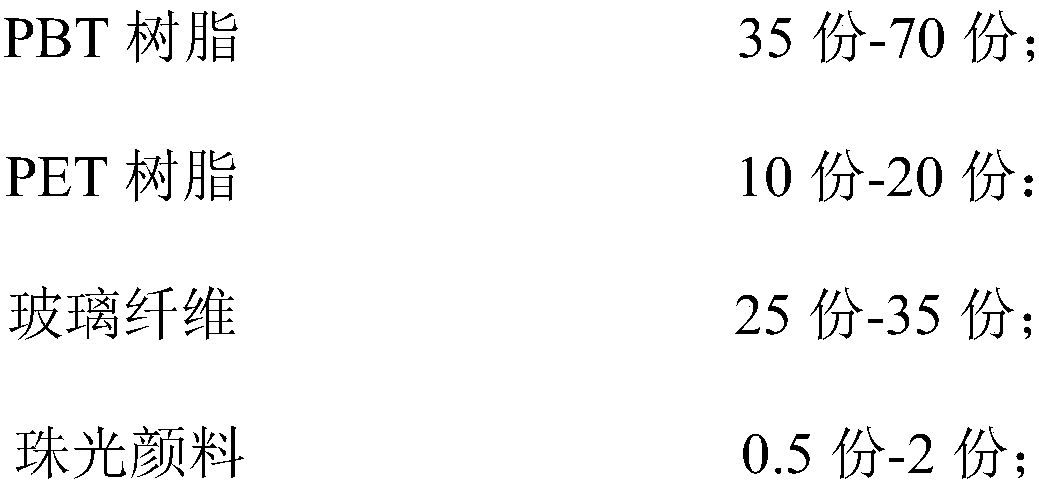

[0032] A spray-free metal effect glass fiber reinforced PBT / PET composition, prepared from the following components in parts by weight: 62 parts of PBT resin; 10 parts of PET resin: 25 parts of glass fiber; 1 part of pearlescent pigment; 2 parts of auxiliary agent parts; the composition also includes tetrahydrofuran, based on the total weight of the composition, the content of tetrahydrofuran is 350ppm.

[0033] The preparation method of the above-mentioned spray-free metal effect glass fiber reinforced PBT / PET composition comprises the following steps:

[0034] Mix tetrahydrofuran and methyl siloxane into a tetrahydrofuran methyl siloxane solution; mix tetrahydrofuran methyl siloxane solution, PBT resin, PET resin and additives in a high-speed mixer for 1-2 minutes to obtain a premix , the premixed material is melt-extruded through a twin-screw extruder at 220°C-240°C, side-fed with glass fibers, cooled, and granulated to obtain a glass fiber-reinforced PBT / PET composition; t...

Embodiment 2

[0036] A spray-free metal effect glass fiber reinforced PBT / PET composition, prepared from the following components in parts by weight: 52 parts of PBT resin; 20 parts of PET resin: 25 parts of glass fiber; 1 part of pearlescent pigment; 2 parts of auxiliary agent parts; the composition also includes tetrahydrofuran, based on the total weight of the composition, the content of tetrahydrofuran is 200ppm.

[0037] The preparation method of the above-mentioned spray-free metal effect glass fiber reinforced PBT / PET composition is the same as that of Example 1.

Embodiment 3

[0039] A spray-free metal effect glass fiber reinforced PBT / PET composition, prepared from the following components in parts by weight: 52 parts of PBT resin; 15 parts of PET resin: 30 parts of glass fiber; 1 part of pearlescent pigment; 2 parts of auxiliary agent parts; the composition also includes tetrahydrofuran, based on the total weight of the composition, the content of tetrahydrofuran is 150ppm.

[0040] The preparation method of the above-mentioned spray-free metal effect glass fiber reinforced PBT / PET composition is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com